Gas interval-type droplet evaporation-resistant micro fluidic chip apparatus and method thereof

A microfluidic chip and anti-evaporation technology, which is applied in the field of microfluidic analysis, can solve problems such as cross-contamination, and achieve the effects of inhibiting evaporation, preventing volume reduction, and avoiding material exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

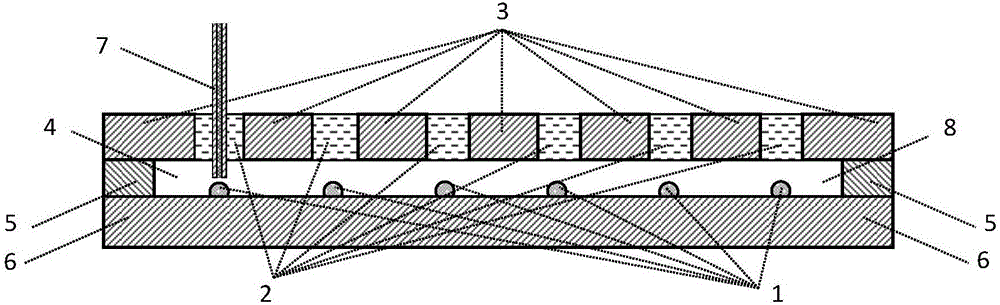

[0069] Microfluidic droplet chip device that prevents droplet evaporation, see figure 1 , figure 1 A longitudinal sectional view of the device. The whole device is circular, placed in a transparent plastic petri dish with a diameter of 6 cm, and the bottom surface of the lower end of the chip device is in contact with the petri dish. The anti-evaporation cover plate 3 with a through hole for carrying the anti-evaporative phase 2 is made of an acrylic plate through laser engraving. 1.0 mm, the anti-evaporation phase is carried in the through hole.

[0070] The bottom surface of the petri dish is directly used as the droplet plate 6 carrying the microdroplet 1, and the thickness is 1.5 mm. There is a layer of annular spacer 5 between the perforated anti-evaporation cover plate 3 and the droplet plate 6, which is made of polydimethylsiloxane (PDMS) material and has a thickness of 3.0 mm, which is used to avoid the droplet 1 and anti-evaporation Phase 2 contacts. Epoxy resin ...

Embodiment 2

[0075] Conventional cell culture is carried out in culture flasks or culture dishes. Cells grow in the container according to their own survival characteristics. Adherent cells grow in a single layer on the surface, and suspension cells grow in suspension in the medium. Conventional cell culture in droplets is to wrap the droplets containing cells and their culture medium in the oil phase for cultivation. However, by using the present invention, the cells and their culture fluid can be cultured in droplets without contacting the anti-evaporation phase, so as to avoid possible interference and adverse effects of the anti-evaporation phase on cell culture.

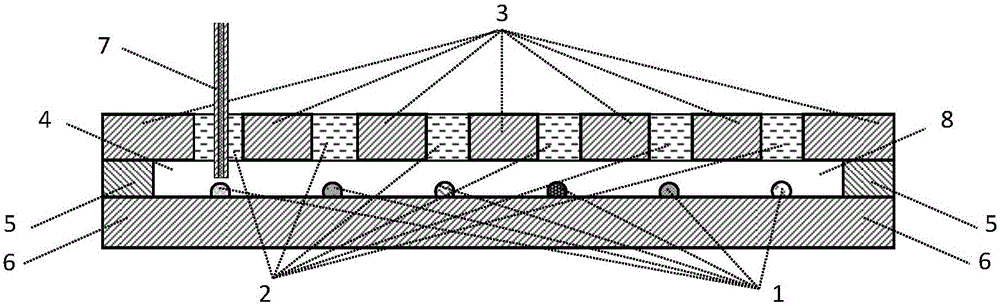

[0076] Non-contact anti-evaporation microfluidic droplet chip device for studying cell droplet culture, see Figure 3a , 3b , 3c and 3d, Figure 3a , 3b , 3c and 3d are longitudinal cross-sectional views of the device. Figure 4a , 4b , 4c and 4d are partial enlarged views corresponding to the above four devices or long...

Embodiment 3

[0084] A microfluidic droplet chip device that can complete the pretreatment of trace protein samples, see Figure 4a , 4b Or 4c, which is a pretreatment device for a sample. Multi-sample, high-throughput pretreatment can be obtained by integrating the above independent devices Figure 3a , 3b or 3d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com