Method of flue gas denitration with ionic liquid and urea

A technology of ionic liquid and urea, which is applied in the field of wet flue gas denitrification, can solve the problems of easy loss, difficult storage and transportation, and strong corrosion, and achieve the effects of low volatility, strong corrosion and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

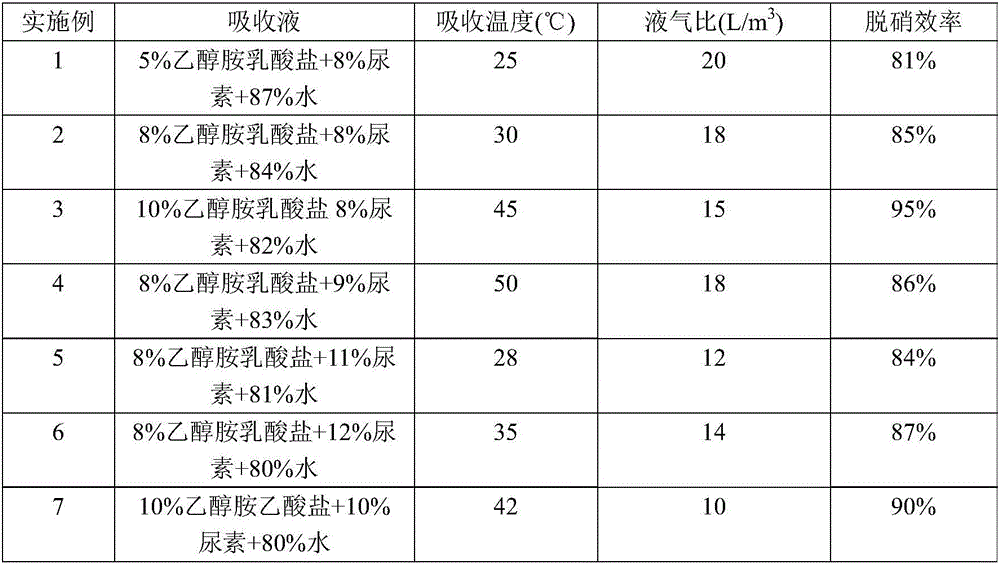

Examples

Embodiment 1

[0023] Ethanolamine lactate ionic liquid and urea are dissolved in water to form an absorption liquid, the mass percentage of ionic liquid in the absorption liquid is 5%, the mass percentage of urea in the absorption liquid is 8%, and then injected into the spray absorption tower , the temperature in the spray absorption tower is 25°C, and the liquid-gas ratio in the spray tower is 20L / m 3 , so that the absorption liquid and the NO 2 The original flue gas is reversely contacted by spraying to realize wet denitrification.

Embodiment 2

[0025] Ethanolamine lactate ionic liquid and urea are dissolved in water to form an absorption liquid, the mass percentage of ionic liquid in the absorption liquid is 8%, the mass percentage of urea in the absorption liquid is 8%, and then injected into the spray absorption tower , the temperature in the spray absorption tower is 30°C, and the liquid-gas ratio in the spray tower is 18L / m 3 , so that the absorption liquid and the NO 2 The original flue gas is reversely contacted by spraying to realize wet denitrification.

Embodiment 3

[0027] Ethanolamine lactate ionic liquid and urea are dissolved in water to form an absorption liquid, the mass percentage of ionic liquid in the absorption liquid is 10%, the mass percentage of urea in the absorption liquid is 8%, and then injected into the spray absorption tower , the temperature in the spray absorption tower is 45°C, and the liquid-gas ratio in the spray tower is 15L / m 3 , so that the absorption liquid and the NO 2 The original flue gas is reversely contacted by spraying to realize wet denitrification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com