Catalyst for coproduction of mixed alcohols and alpha-olefin through synthesis gas one-step method and preparing method and application thereof

A catalyst and synthesis gas technology, which is applied in the field of catalysts and preparations for the one-step co-production of mixed alcohols and α-olefins in synthesis gas, and can solve the problems of failure to realize industrialization, activity, selectivity, stability and unsatisfactory economy. , to achieve strong industrial application prospects, good stability and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

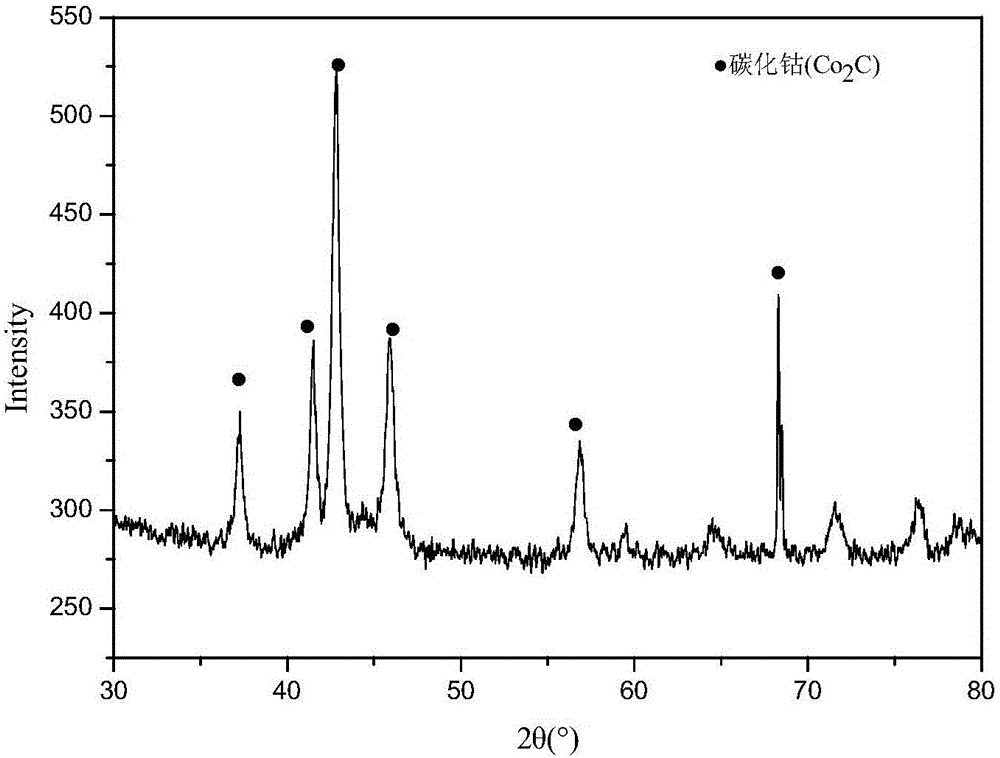

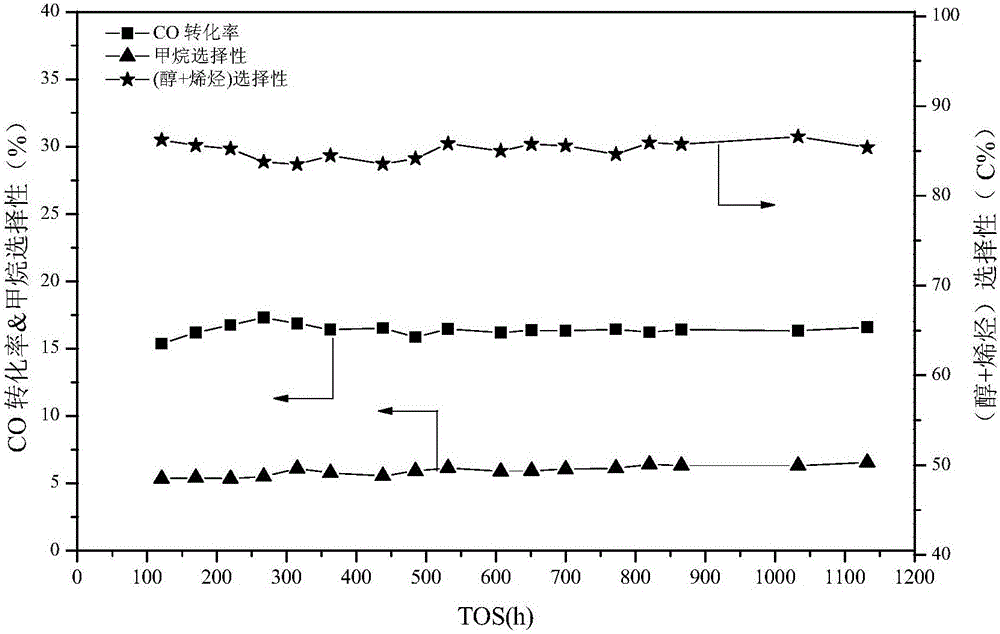

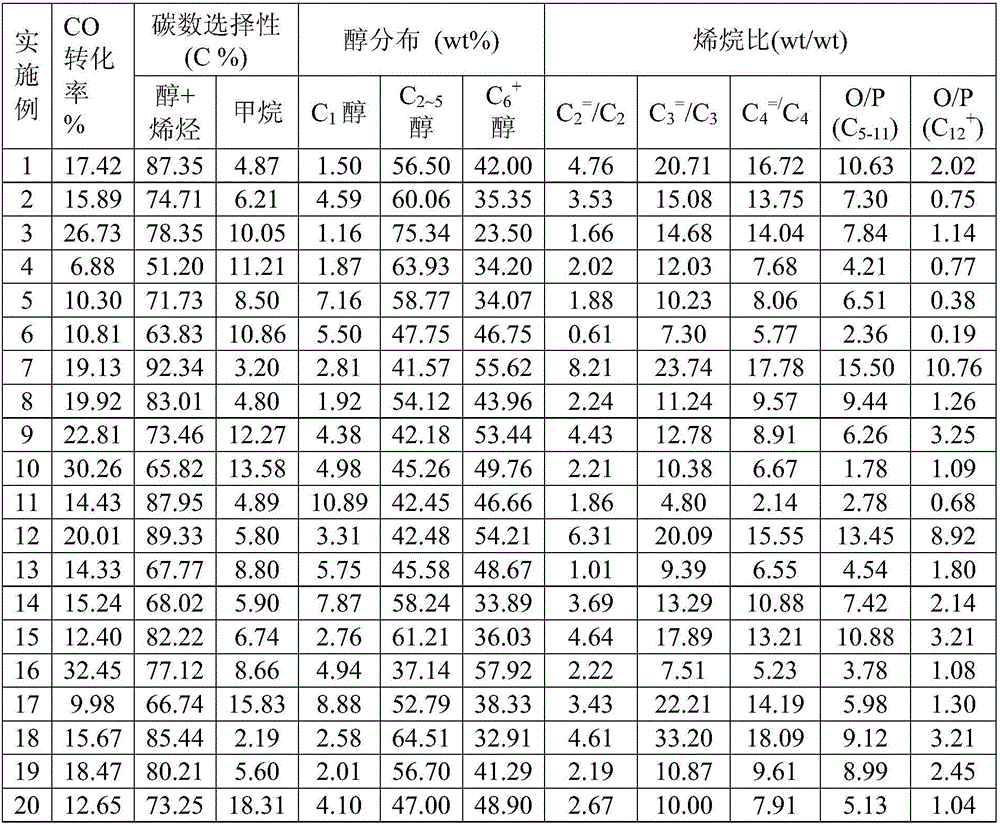

Embodiment 1

[0062] 50%Mn(NO 3 ) 2 Aqueous solution and Co(NO 3 ) 2 ·6H 2 O is dissolved in a certain amount of deionized water according to the molar ratio Co / Mn=3 / 1 to form a mixed solution with a total metal concentration of 2mol / L, and then dissolve sodium carbonate in a certain amount of deionized water to form a concentration of 2mol / L L lye. The titration temperature was adjusted to 40° C., the titration pH was controlled to be 8, and the above two solutions were co-precipitated in a co-current manner. After the titration, it was aged at 40°C for 4 hours, centrifuged and washed until the pH was neutral, and then dried in an oven at 100°C for 12 hours. Then, sodium carbonate was used as the metal salt precursor of the impregnating solution, and an equal volume of 1 wt% sodium was used to impregnate (Referring to the percentage of M1 accounting for the total mass of the catalyst, the following examples are the same, that is, M1 is sodium, accounting for 1wt% of the total mass of ...

Embodiment 2

[0065] 50%Mn(NO 3 ) 2 Aqueous solution and Co(NO 3 ) 2 ·6H 2 O is dissolved in a certain amount of deionized water according to the molar ratio Co / Mn=3 / 1 to form a mixed solution with a total metal concentration of 2mol / L, and then dissolve sodium carbonate in a certain amount of deionized water to form a concentration of 2mol / L L lye. The titration temperature was adjusted to 40° C., the titration pH was controlled to be 8, and the above two solutions were co-precipitated in a co-current manner. After the titration, it was aged at 40°C for 4 hours, centrifuged and washed until the pH was neutral, and then dried in an oven at 100°C for 12 hours. Then, potassium carbonate was used as the metal salt precursor of the impregnating solution, and an equal volume of 1 wt% potassium was impregnated. , after being air-dried, place it in an oven at 120°C for drying, and finally transfer to a muffle furnace and heat up to 400°C for 5 hours of roasting. The catalyst is obtained afte...

Embodiment 3

[0068] 50%Mn(NO 3 ) 2 Aqueous solution and Co(NO 3 ) 2 ·6H 2 O is dissolved in a certain amount of deionized water according to the molar ratio Co / Mn=3 / 1 to form a mixed solution with a total metal concentration of 0.5mol / L, and then dissolve sodium carbonate in a certain amount of deionized water to form a concentration of 0.5 mol / L lye. The titration temperature was adjusted to 65° C., the titration pH was controlled to be 8, and the above two solutions were co-precipitated in a co-current manner. After the titration, it was aged at 65°C for 6 hours, centrifuged and washed until the pH was neutral, and then dried in an oven at 100°C for 12 hours. Then, sodium carbonate was used as the metal salt precursor of the impregnation solution, and an equal volume of 1 wt% sodium was used to impregnate , after being air-dried, place it in an oven at 120°C for drying, and finally transfer to a muffle furnace and heat up to 400°C for 5 hours of roasting. The catalyst is obtained a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com