Preparation method and application of compound photocatalyst for growth of ZnIn2S4 on surfaces of TiO2 hollow spheres

A surface growth, hollow sphere technology, applied in physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as no reports, and achieve convenient operation, mild reaction conditions, and energy consumption. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

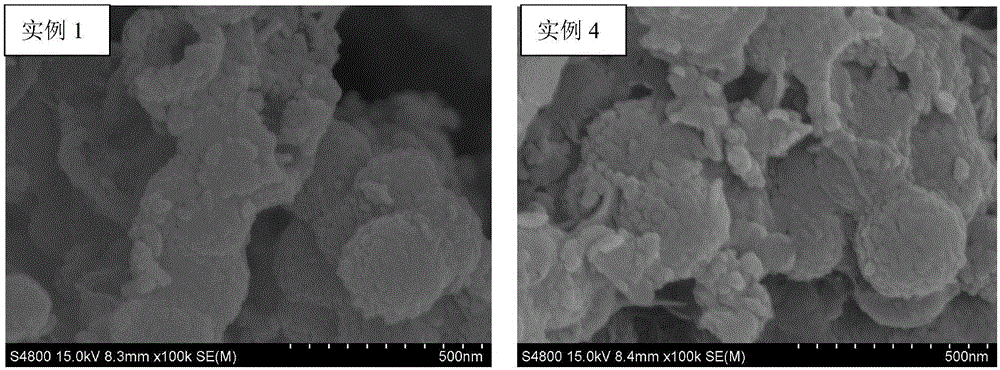

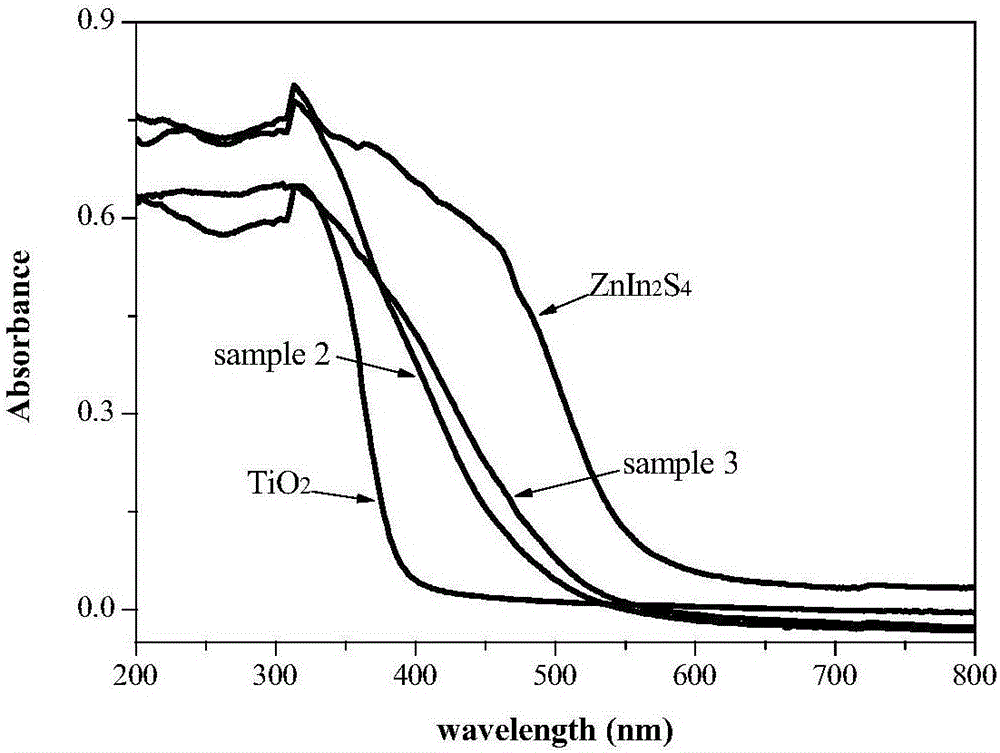

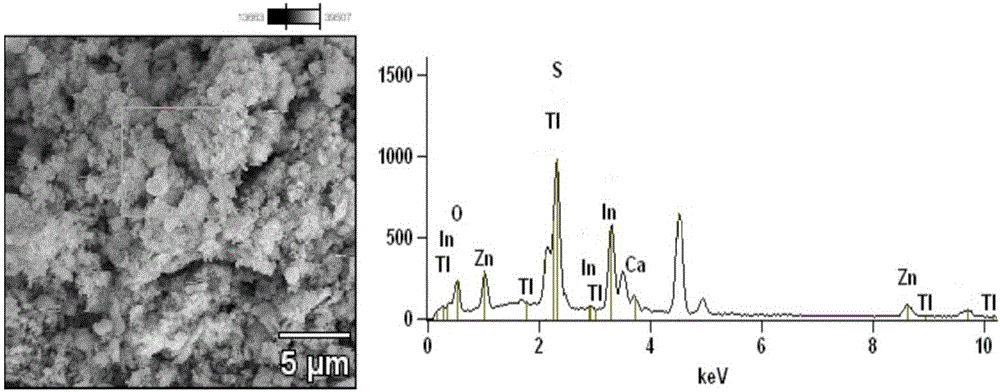

[0027] (1) Weigh 0.05g TiO 2 Hollow sphere, TiO 2 The diameter of the hollow sphere is 200-400nm. Measure 20mL of twice distilled water in a beaker, sonicate for 10min, and then stir for 2h to obtain TiO 2 Hollow sphere dispersion.

[0028] (2) Weigh 0.052g zinc nitrate, 0.115g indium nitrate, 0.069g thioacetamide (TAA) and 0.045g cetyltrimethylammonium bromide (CTAB) in sequence and add them to step (1) to prepare TiO 2 hollow sphere dispersion; then the suspension was stirred for 2 hours; then the suspension was transferred to a reaction kettle for reaction; the reaction temperature was 160°C, and the reaction time was 6 hours. After the reaction, after cooling to room temperature, the obtained product was washed several times with deionized water and absolute ethanol, and dried in vacuum to obtain TiO 2 Growth of ZnIn on the surface of hollow spheres 2 S 4 Composite photocatalyst, where ZnIn 2 S 4 The content of the composite photocatalyst is 45.8%.

[0029] With ...

example 2

[0032] (1) Weigh 0.1g TiO 2 Hollow sphere, TiO 2 The diameter of the hollow sphere is 200-400nm. Measure 30mL of twice distilled water in a beaker, sonicate for 5min, and then stir for 2h to obtain TiO 2 Hollow sphere dispersion.

[0033] (2) Weigh successively 0.103g of zinc nitrate, 0.224g of indium nitrate, 0.135g of thioacetamide (TAA) and 0.090g of cetyltrimethylammonium bromide (CTAB) into step (1) to obtain TiO 2 hollow sphere dispersion; then the suspension was stirred for 2 hours; then the suspension was transferred to a reaction kettle for reaction; the reaction temperature was 160°C, and the reaction time was 7 hours. After the reaction, after cooling to room temperature, the obtained product was washed several times with deionized water and absolute ethanol, and dried in vacuum to obtain TiO 2 Growth of ZnIn on the surface of hollow spheres 2 S 4 Composite photocatalyst, where ZnIn 2 S 4 The content of the composite photocatalyst is 55.9%.

[0034] The ph...

example 3

[0037] (1) Weigh 0.30g TiO 2 Hollow sphere, TiO 2 The diameter of the hollow sphere is 200-400nm. Measure 80mL of twice distilled water in a beaker, sonicate for 15min, and then stir for 3h to obtain TiO 2 Hollow sphere dispersion.

[0038] (2) Sequentially weigh 0.034g zinc nitrate, 0.076g indium nitrate, 0.045g thioacetamide (TAA) and 0.030g cetyltrimethylammonium bromide (CTAB) and add them to step (1) to prepare TiO 2 hollow sphere dispersion; then the suspension was stirred for 2 hours; then the suspension was transferred to a reaction kettle for reaction; the reaction temperature was 180°C, and the reaction time was 8 hours. After the reaction, after cooling to room temperature, the obtained product was washed several times with deionized water and absolute ethanol, and dried in vacuum to obtain TiO 2 Growth of ZnIn on the surface of hollow spheres 2 S 4 Composite photocatalyst, where ZnIn 2 S 4 The content of the composite photocatalyst is 12.4%.

[0039] Visi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com