Regeneration method for failure polyethylenimine-modified cation exchange membranes

A technology of cation exchange membrane and polyethyleneimine, which is applied in the field of regeneration of cation exchange membrane, can solve problems such as invalidation, pollution, monovalent selectivity of single cation exchange membrane, achieve prolong life, improve cross-linking stability, and the method is simple and easy line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

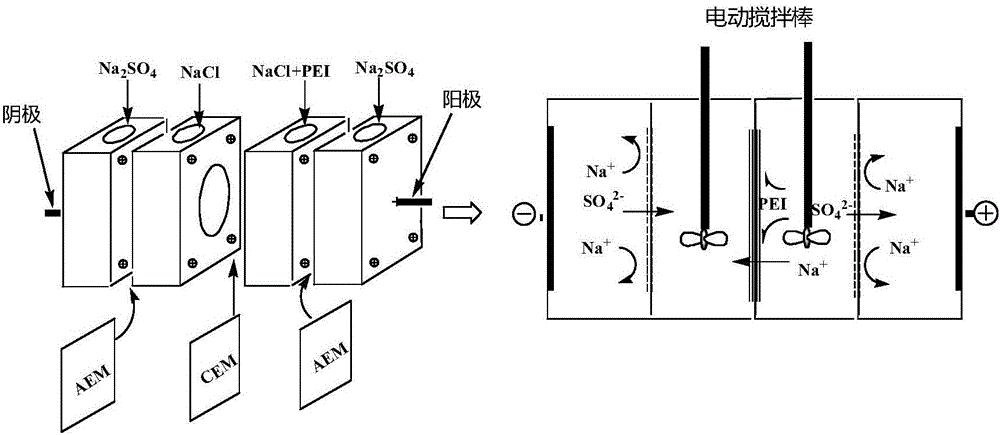

[0036] Japanese SELEMION that loses ion selectivity after industrial application TM The cation exchange membrane is an invalid membrane, soaked in 10% methanol solution and treated with ultrasonic vibration at 60kHz for 2h, then soaked in 0.05M dilute sulfuric acid solution and treated with ultrasonic vibration at 60kHz for 2h, in order to eliminate the monovalent selective functional failure membrane The pollutants on the surface and the chemically degraded polyethyleneimine (PEI) functional groups were rinsed three times with deionized water after two ultrasonic treatments to remove the residual solution on the surface, and then used figure 1 The electrodeposition apparatus shown performs electrodeposition.

[0037] Fix the cation exchange membrane to be deposited in the middle, and the two auxiliary membranes are Japanese SELEMION TM anion exchange membrane. When energized, the two sides of the film to be deposited form a concentrated chamber and a dilute chamber respecti...

Embodiment 2

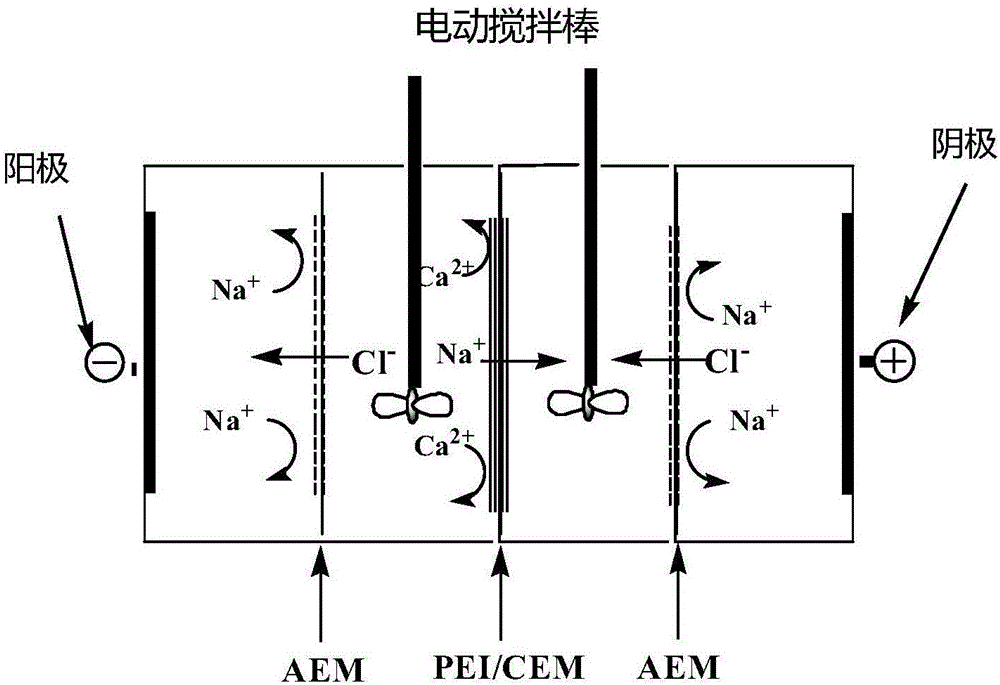

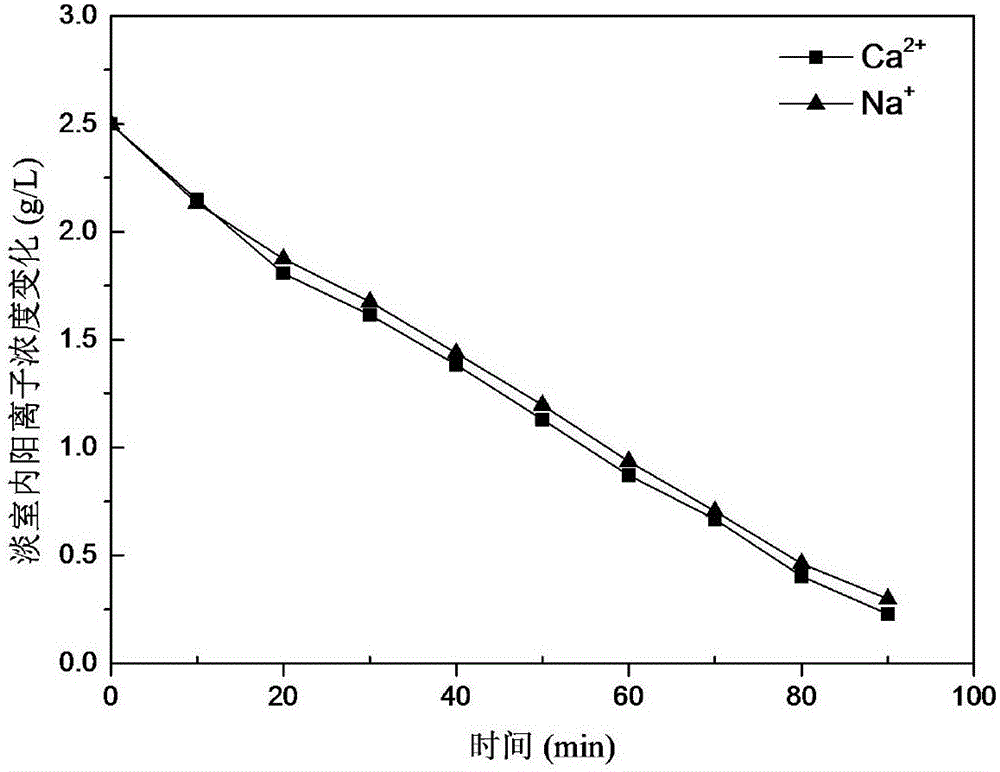

[0040] According to embodiment 1, add sodium chloride concentration in the dilute chamber and be 0.5mol / L, the mixed solution that polyethyleneimine concentration is reduced to 2g / L, be the sodium chloride solution of 0.5mol / L in the concentrated chamber, with 0.2 The mol / L sodium sulfate solution is used as the electrolyte solution in the electrode chamber, and the current on the membrane surface is kept at 10mA / cm 2The deposition of polyethyleneimine on the film was completed after energizing for 0.5 hours; the film deposited with polyethyleneimine was taken out, the surface of the film was cleaned with deionized water, and then placed in an aqueous solution of epichlorohydrin with a volume concentration of 20% for crosslinking for 2 hours; The cross-linked membrane is rinsed with ultrapure water to remove the surface cross-linking agent, and then the membrane is tested in an electrodialysis device according to Example 1, and the change of the modified membrane over time—the ...

Embodiment 3

[0042] According to embodiment 1, adding the concentration of sodium chloride in the dilute chamber is a mixed solution of 0.5mol / L and polyethylenimine concentration of 2g / L; The sodium sulfate solution is used as the electrolyte solution in the electrode chamber, and the surface current of the electrodeposited film is adjusted to 20mA / cm 2 The deposition of polyethyleneimine on the film is completed under electricity and energized for 0.5 hours; then the film deposited with polyethyleneimine is taken out, the surface of the film is cleaned with deionized water, and then cross-linked in an aqueous solution of epichlorohydrin with a volume concentration of 20%. 2h; the membrane after crosslinking is rinsed with ultrapure water to remove the surface crosslinking agent, and then the membrane is tested in an electrodialysis device according to Example 1, and the change of the concentration of divalent cations over time of the modified membrane is as follows Image 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com