Adhesive composition, adhesive layer, surface protective film, and optical member

A surface protection film and adhesive layer technology, applied in the direction of non-polymer adhesive additives, adhesive types, adhesive additives, etc., can solve problems such as difficult to suppress, difficult to obtain high cross-linking, to prevent Increased adhesion, excellent cross-linking stability, and high cross-linking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

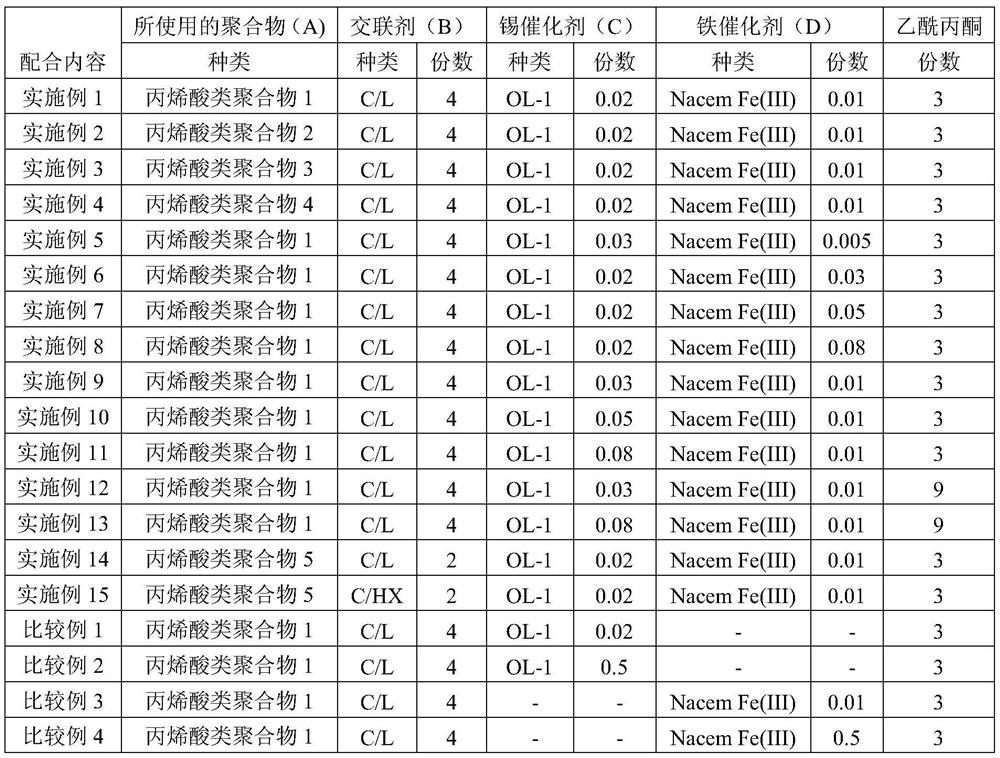

[0109] Hereinafter, Examples etc. which specifically show the structure and effect of this invention are demonstrated, However, this invention is not limited to these Examples. In addition, the evaluation item in an Example etc. was measured as follows.

[0110]

[0111] 96.2 parts by mass of 2-ethylhexyl acrylate (2EHA), 3.8 parts by mass of hydroxyethyl acrylate (HEA), and 2 , 0.2 parts by mass of 2'-azobisisobutyronitrile, 150 parts by mass of ethyl acetate, introducing nitrogen gas while stirring slowly, keeping the liquid temperature in the flask at about 65°C and performing polymerization reaction for 6 hours, thereby preparing Acrylic polymer 1 solution (40% by mass). The weight average molecular weight (Mw) of the said acrylic polymer 1 was 540,000, and the glass transition temperature (Tg) was -68 degreeC.

[0112]

[0113] Put 98.5 parts by mass of 2-ethylhexyl acrylate (2EHA) and 1.5 parts by mass of 4-hydroxybutyl acrylate (4HBA) into a four-necked flask with...

Embodiment 2

[0126] A surface protection film was produced by the method similar to Example 1 except having used the acrylic polymer 2 instead of the acrylic polymer 1 used in Example 1.

Embodiment 3

[0128] A surface protection film was produced by the method similar to Example 1 except having used the acrylic polymer 3 instead of the acrylic polymer 1 used in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com