Grinding pad for gallium oxide single crystals and preparation method of grinding pad

A technology of grinding pads and gallium oxide, which is applied in the direction of grinding tools, grinding/polishing equipment, grinding devices, etc., can solve the problems of complicated manufacturing process, high cost of raw materials, increased workload of workers, etc., so as to improve the use efficiency, Avoid the effects of cleavage pits and free shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

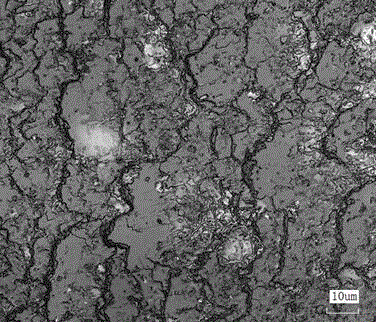

Image

Examples

Embodiment 1

[0032] A polishing pad for gallium oxide single crystal, comprising elastic crepe and a mixed abrasive grain rubber layer from bottom to top, and the mixed abrasive grain rubber layer is mixed with resin glue, diamond micropowder of W3 and water-soluble grinding aid made.

[0033] The preparation method of the polishing pad for the above-mentioned gallium oxide single crystal comprises the following steps:

[0034] Step 1, choose elastic crepe satin as the base of the abrasive pad;

[0035] Step 2, according to the mass fraction, weigh water-soluble resin INTAN TP 340 30%, abrasive 10%, PEG-1000 5%, alkanolamide 1.5%, carbomer 2%, and the balance is deionized water;

[0036] Step 3, weighing the above-mentioned material components according to an appropriate ratio, adding resin glue, grinding aids, abrasives, and deionized water in sequence, and stirring evenly to obtain the first mixture;

[0037] Step 4, the first mixture is evenly sprayed on the surface of the cloth base ...

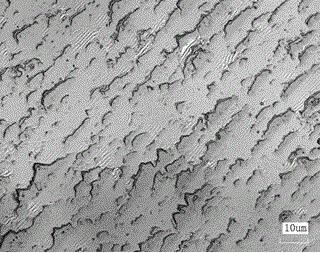

Embodiment 2

[0041] A polishing pad for gallium oxide single crystals, which comprises, from bottom to top, a silk elastic bismuth, a mixed abrasive grain rubber layer, and the mixed abrasive grain rubber layer is mixed with resin glue, diamond micropowder of W1 and water-soluble grinding aids made.

[0042] The preparation method of the polishing pad for the above-mentioned gallium oxide single crystal comprises the following steps:

[0043] Step 1, choose silk elastic double joe as the cloth base of the abrasive pad;

[0044] Step 2, according to the mass fraction, weigh water-soluble resin glue INTAN TP 340 25% and PUR WX 1418 10%, abrasive 5%, PEG-800 5%, alkanolamide 1%, carbomer 1%, the balance is deionized water;

[0045] Step 3, weighing the above-mentioned material components according to an appropriate ratio, adding resin glue, grinding aids, abrasives, and deionized water in sequence, and stirring evenly to obtain the first mixture;

[0046] Step 4, uniformly spraying the fir...

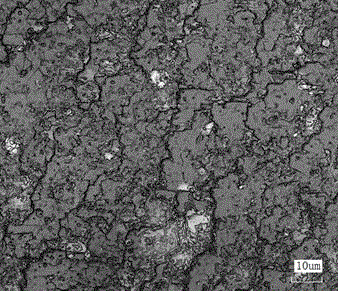

Embodiment 3

[0050] A polishing pad for gallium oxide single crystal, which comprises silk elastic spinning from bottom to top, a mixed abrasive grain rubber layer, and the mixed abrasive grain rubber layer is composed of resin glue, diamond micropowder of W1.5 and water-soluble grinding aid mixed.

[0051]The preparation method of the polishing pad for the above-mentioned gallium oxide single crystal comprises the following steps:

[0052] Step 1, choose silk stretch spinning as the cloth base of the abrasive pad;

[0053] Step 2, according to the mass fraction, weigh water-soluble resin glue INTAN TP 340 30%, PUR WX 1418 10%, RPU069 5%, abrasive 10%, PEG-600 5%, fatty amide sulfosuccinic acid monoester 1 %, Carbomer 1%, the balance is deionized water;

[0054] Step 3, weighing the above-mentioned material components according to an appropriate ratio, adding resin glue, grinding aids, abrasives, and deionized water in sequence, and stirring evenly to obtain the first mixture;

[0055] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com