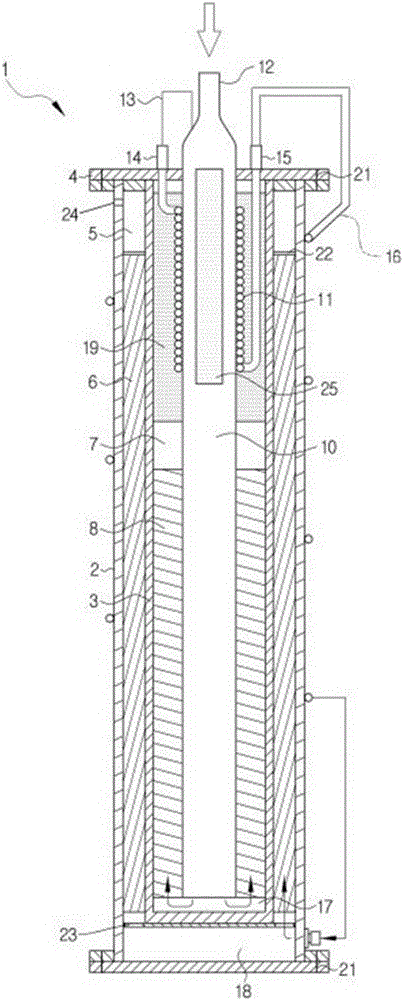

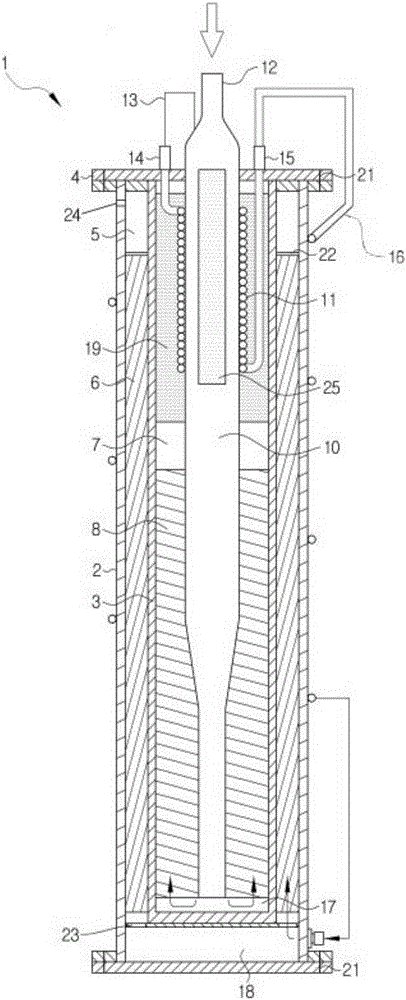

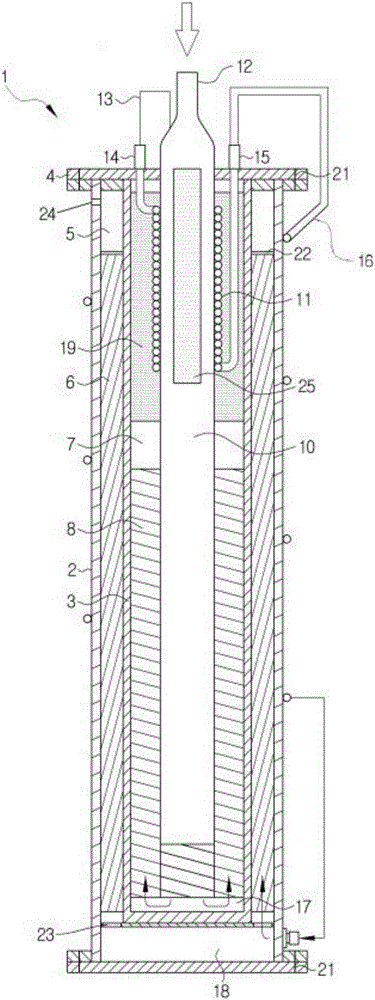

A hydrogen production reactor

A hydrogen production reactor and reactor technology, applied in hydrogen, electrochemical generator, hydrogen/synthesis gas production, etc., can solve problems such as difficult heat supply, low output power, and low thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0153] The reforming part is filled with a copper (Cu) component catalyst made in the shape of a tray with an average diameter of 1.5mm as a reforming catalyst, and the combustion part is filled with platinum (Pt) made in the shape of a ceramic honeycomb. )catalyst. The preheating pipe uses a 1 / 8-inch pipe, and winds the outside of the reforming section into a coil shape at equal intervals according to the height, so that the vaporized reforming raw material is further preheated by the heat supplied by the reforming section on the outer wall.

[0154] As a raw material, a liquid fuel prepared by mixing 60% by weight of methanol and 40% by weight of distilled water on a mass basis was used. In addition, the same liquid fuel is used for the heating raw material and the reforming raw material. As a reforming raw material, the liquid fuel was supplied at 7.8 g / min. The heating raw material is supplied at a flow rate of 2.9g / min. For combustion, the Air is supplied at the same ...

Embodiment 2

[0158] The reforming part is filled with a copper (Cu) component catalyst manufactured in the shape of a tray with an average diameter of 1.5 mm as a reforming catalyst, and the combustion part is filled with platinum (Cu) made in a ceramic honeycomb shape. Pt) catalyst. The preheating pipe uses a 1 / 8-inch pipe, and winds the outside of the reforming section into a coil shape at equal intervals according to the height, so that the vaporized reforming raw material is further preheated by the heat supplied by the reforming section on the outer wall. In addition, a catalyst composed of ruthenium (Ru) produced in a tray shape with an average diameter of 1.5 mm was filled in the carbon monoxide removal unit at the end of the reformer unit.

[0159] As a raw material, a liquid fuel prepared by mixing 60% by weight of methanol and 40% by weight of distilled water on a mass basis was used. In addition, the same liquid fuel is used for the heating raw material and the reforming raw ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com