System and method for intelligently controlling sewage plant on basis of nitrogen balance

An intelligent control system and technology for sewage treatment plants, applied in water treatment parameter control, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problem of destroying denitrifying bacteria, favorable denitrification environment, substandard removal of total nitrogen, inclusions, etc. problem, to achieve the effect of saving energy consumption of aeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

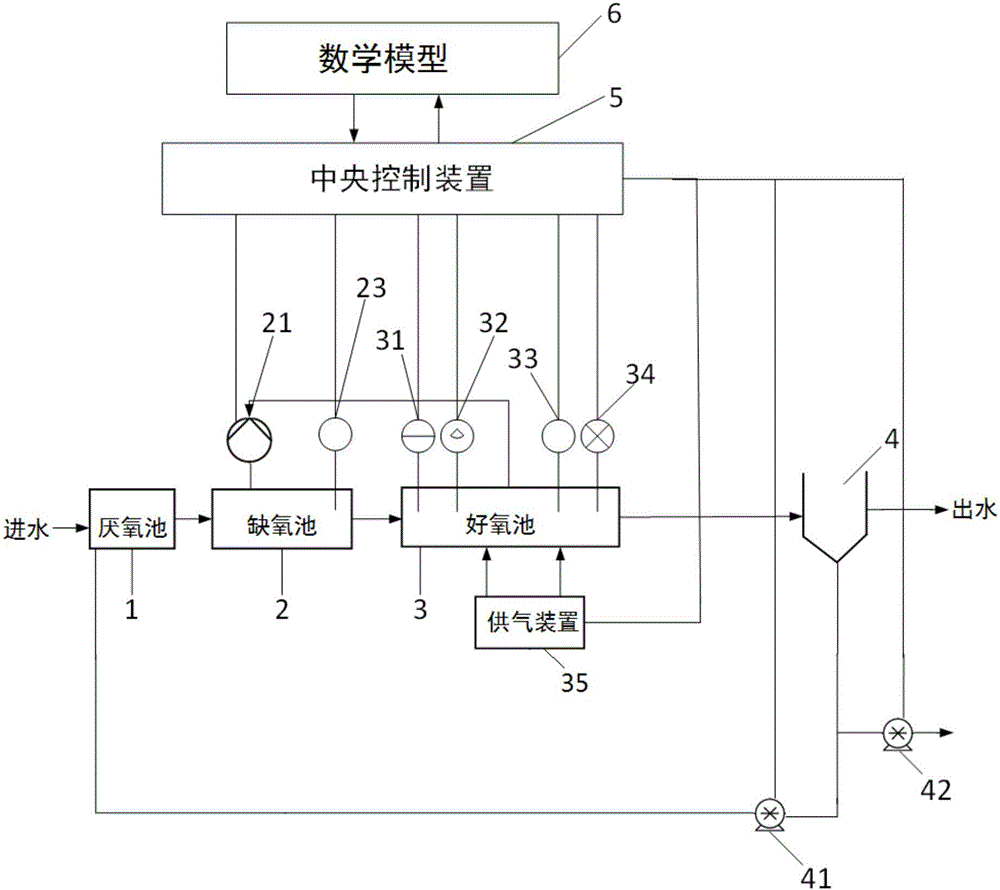

[0018] Such as figure 1 As shown, it is a structural schematic diagram of an intelligent control system of a sewage plant based on nitrogen balance in this embodiment.

[0019] A kind of sewage plant intelligent control system based on nitrogen balance, comprising anaerobic pond 1, anoxic pond 2, aerobic pond 3, sedimentation pond 4, central control device 5 and mathematical model 6, described anaerobic pond 1, anoxic pond Pool 2, aerobic pool 3 and sedimentation tank 4 are connected successively by pipelines, a reflux pump 21 is provided between the anoxic pool 2 and the aerobic pool 3, and the central control device 5 is connected with the mathematical model 6, so The central control device 5 is also respectively connected to the air supply device 35 for aeration in the aerobic pool 3, the first ammonia nitrogen detector 23 for measuring the actual value of ammonia nitrogen in the anoxic pool 2, and the first ammonia nitrogen detector 23 for measuring the actual value of amm...

Embodiment 2

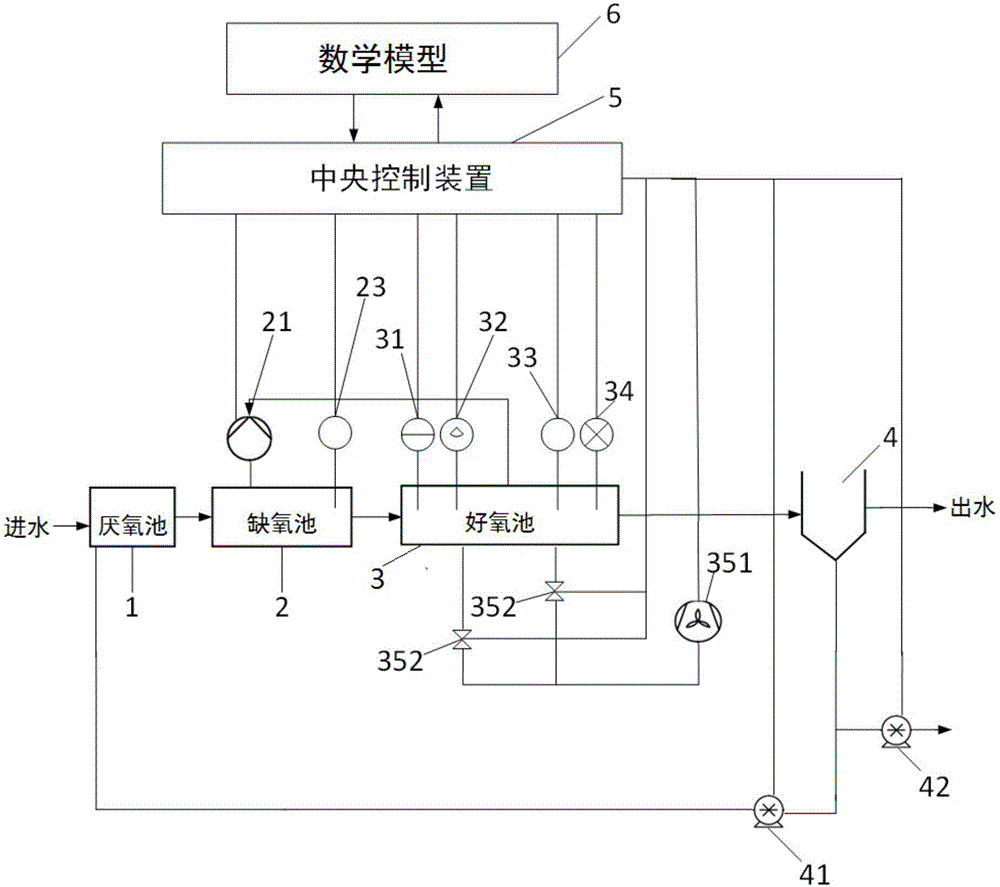

[0026] As mentioned above, the intelligent control system of sewage plant based on nitrogen balance, the difference of this embodiment is that, as figure 2 As shown, the air supply device 35 includes a fan 351 and a plurality of flow regulating valves 352 connected to the fan 351, each of the flow regulating valves 352 is connected to each of the partition sections in the aerobic pool 3 The fan 351 and each of the flow regulating valves 352 are connected to the central control device 5 .

[0027] The control method is as follows: the mathematical model 6 calculates the aeration amount required for the ammonia nitrogen in each of the partitions to reach the target value according to the set value of dissolved oxygen and the actual value of dissolved oxygen, and through the central control device 5 Control the output of the air volume of the fan 351, and then quickly and accurately adjust the opening of the flow regulating valve 352 to complete the distribution of the required ...

Embodiment 3

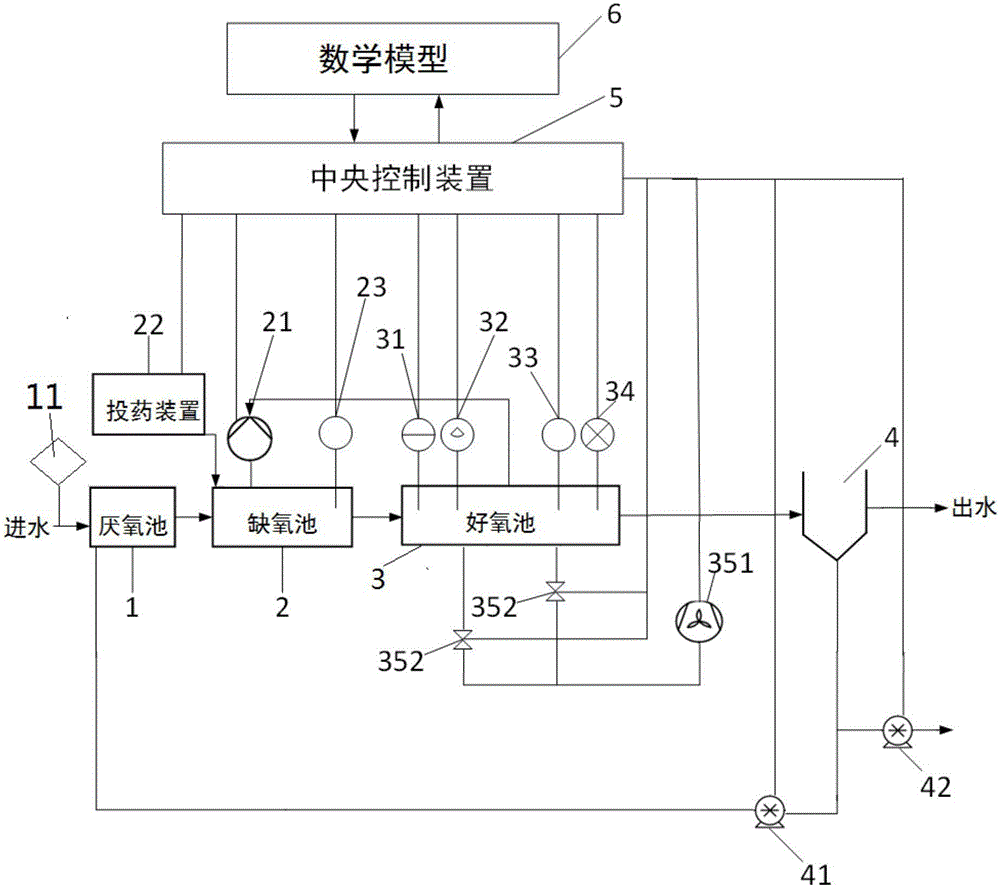

[0029] As mentioned above, the intelligent control system of sewage plant based on nitrogen balance, the difference of this embodiment is that, as image 3 As shown, the anoxic pool 2 is provided with a dosing device 22, which is used to add a carbon source to the anoxic pool 2, and the water inlet is provided with a COD measuring instrument 11, and the dosing device 22, The nitrate nitrogen measuring instrument 34 and the COD measuring instrument 11 are respectively connected with the central control device 5;

[0030] The mathematical model 6 calculates the conversion rate of ammonia nitrogen into nitrate nitrogen according to the actual value of ammonia nitrogen measured by the first ammonia nitrogen measuring instrument 23, the biomass measured by the online sludge concentration detector 32, and the set effluent ammonia nitrogen target value. concentration and calculate the dissolved chemical oxygen demand required for denitrification to remove this nitrate nitrogen, combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com