Automatic control equipment and method for preparing organic-inorganic mixed fertilizer from garden greening waste compost

A landscaping and waste technology, applied in the field of automatic control equipment, can solve the problem of low nutrient content of compost, achieve the effect of increasing nutrient content, shortening composting time, and reducing phosphorus fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

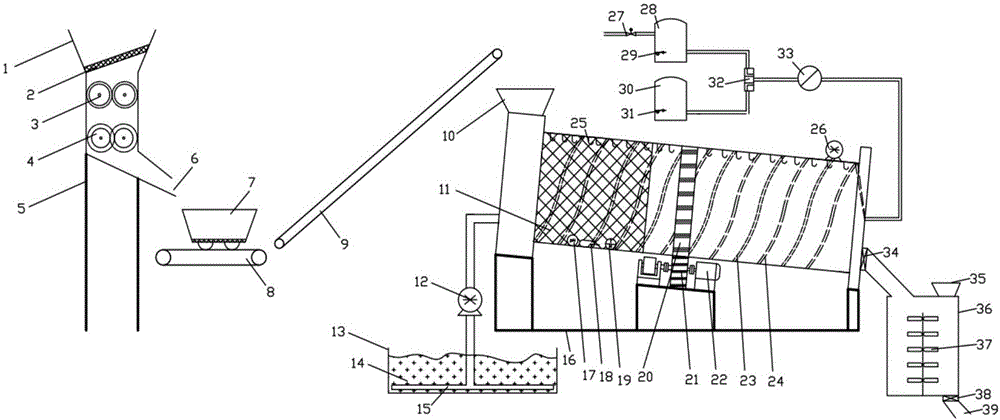

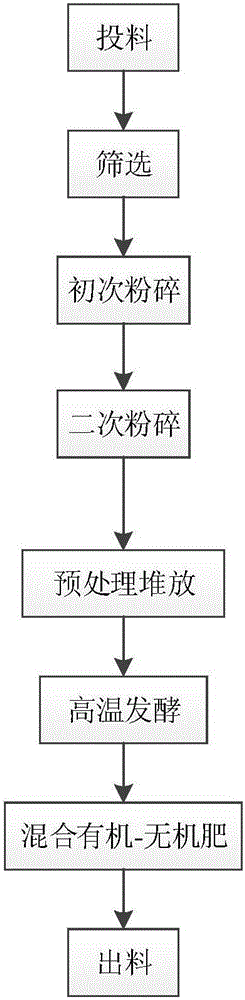

[0058] After the thick branches (diameter ≥ 1.5cm) of the garden waste are selected and separated, they are fed and crushed by the feed port 1 of the pulverizer. The garden waste is pulverized by the primary pulverizer 3, and the particle size is ≤ 20mm, and the particle size is pulverized by the secondary pulverizer 4. The diameter is less than or equal to 5mm, and then the material is discharged through the discharge port 6 of the pulverizer.

[0059] The pulverized material enters the movable bucket truck 7 for material pretreatment, and the C / N of the pulverized material is adjusted to be (25-30):1, and the moisture content is 55%-65%. After the above-mentioned pretreatment, the material reaches the entrance 10 of the fermentation bin through the translation device 8 and the lifting device 9, and the composting process begins after the material enters the fermentation bin body.

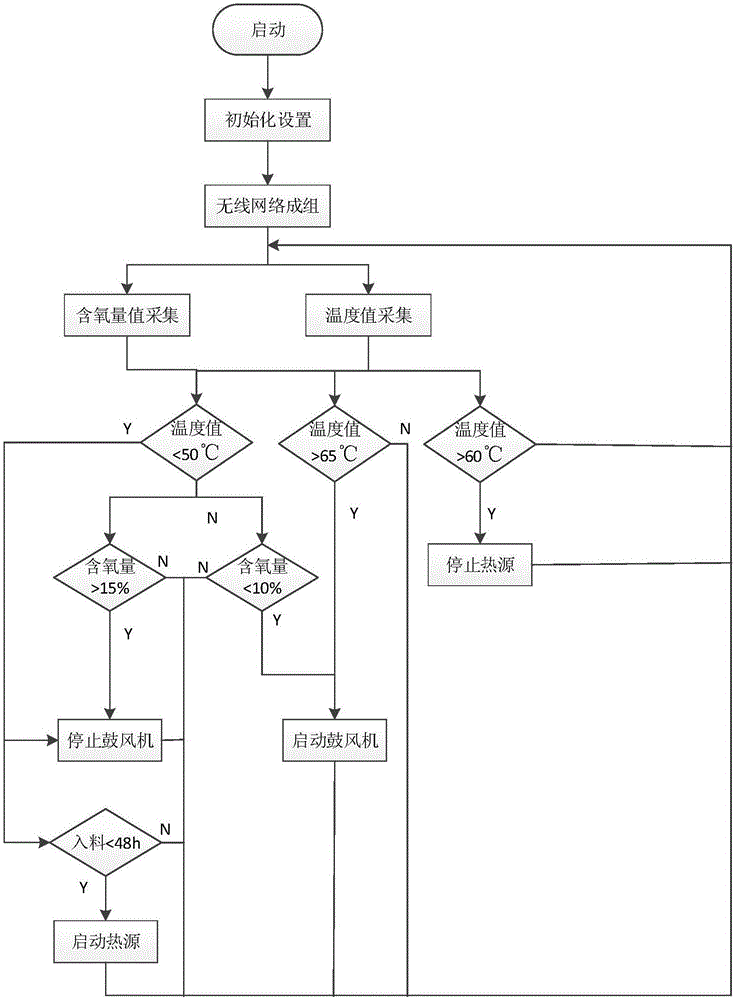

[0060] In the composting process, the initial temperature and oxygen content adjustment contro...

Embodiment 2

[0065] The operation steps and composting treatment conditions are the same as in Example 1, the difference is that the composting material is fermented and decomposed through 12 to 15 days, and ammonium sulfate, superphosphate, and chlorine are added to the organic-inorganic mixed fertilizer device 36 through the batching port 35 Potassium chloride, ammonium sulfate, superphosphate, potassium chloride, and compost decomposed clinker are in a mass ratio of 12:6:1:40. The organic-inorganic fertilizer produced in this example can be used as the base fertilizer for wheat.

Embodiment 3

[0067] The operation steps and composting treatment conditions are the same as in Example 1, except that the composting material is fermented and decomposed for 12 to 15 days, and ammonium sulfate, monoammonium phosphate, sulfuric acid are added to the organic-inorganic mixed fertilizer device 36 through the batching port 35 The mass ratio of potassium, ammonium sulfate, superphosphate, potassium chloride and compost decomposed clinker is 11:5:6:90. The organic-inorganic fertilizer produced in this embodiment can fertilize some crops that have high requirements for phosphorus and potassium and slightly lower nitrogen, such as potatoes and onions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com