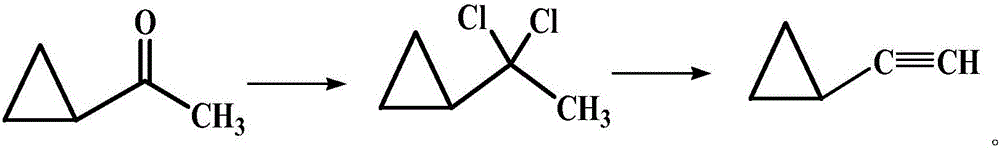

Preparation method of cyclopropyl acetylene

A technology of cyclopropyl acetylene and cyclopropane ketone, which is applied in the field of preparation of cyclopropyl acetylene, can solve problems such as waste of resources and environmental pollution, and achieve the effects of less environmental pollution, reduced pollution and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] Preparation of reaction medium:

[0017] Take a certain amount of crushed waste polyester bottle material, add methanol solution to at least submerge the waste polyester bottle material, heat and reflux until the waste polyester bottle material is completely dissolved, filter out the insoluble matter while it is hot, and obtain a mixture after alcoholysis [(methyl terephthalate (DMT) and ethylene glycol (EG))] for the following reaction.

Embodiment 1

[0019] In the reactor, add 84 grams (1 mole) of cyclopropyl ketone, 208.5 grams (1 mole) of phosphorus pentachloride, utilize the mixture [methyl terephthalate (methyl terephthalate ( DMT) and ethylene glycol (EG)] 404.5 grams, stirred and reacted for 5 hours at a temperature of 0°C, added 112 grams (2 moles) of potassium hydroxide, continued to stir and react at the same temperature, and gas chromatographic tracking was detected until the end of the reaction. After filtering off the solid matter, 49 g of the product was purified by rectification, with a yield of 74%, a boiling point of 52-53°C, and a cyclopropylacetylene content of ≥98% as determined by HPLC.

Embodiment 2

[0021] In the reactor, add 84 grams (1 mole) of cyclopropyl ketone, 417 grams (2 moles) of phosphorus pentachloride, utilize the mixture [methyl terephthalate (methyl terephthalate ( DMT) and ethylene glycol (EG)] 2000 grams, stirred and reacted at -5 ℃ for 5 hours, added 224 grams (4 moles) of potassium hydroxide, continued to stir and react at the same temperature, and gas chromatography tracked and detected until the end of the reaction. After filtering off the solid matter, 48 g of the product was purified by rectification, with a yield of 73%, a boiling point of 52-53°C, and a cyclopropylacetylene content of ≥98% as determined by HPLC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com