A kind of preparation method of multi-layer structure wave absorbing agent

A multi-layer structure and wave absorbing agent technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem of narrow wave absorption frequency band, achieve the effect of wide absorption frequency band, broaden absorption frequency band width, and high electromagnetic wave loss capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

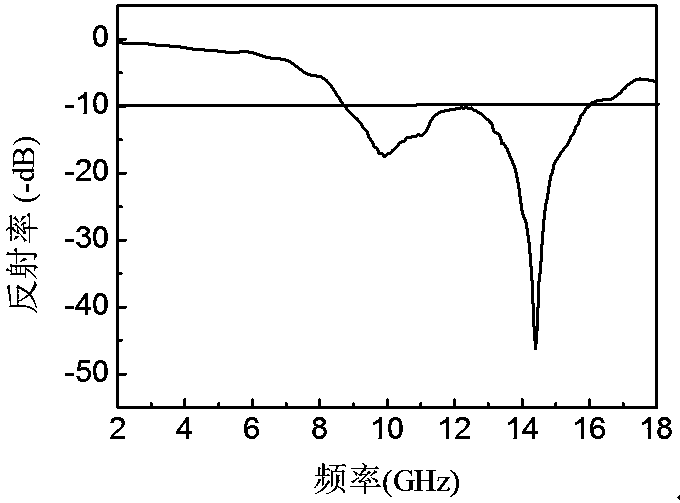

[0025] Embodiment 1: A preparation method of a wave absorbing agent with a similar multi-layer structure is carried out according to the following steps.

[0026] 1. Preparation of hollow porous activated carbon fiber-carbon nanotube dielectric loss layer absorber: use polypropylene nitrile-based hollow porous carbon fiber as the matrix, and use electroplating to load nano-Ni catalyst particles on its surface. The electroplating time is 1s, and then Wash several times with distilled water and dry. Carbon nanotubes are grown on the surface by chemical vapor deposition.

[0027] 2. Preparation of polyacrylonitrile-based hollow porous carbon fiber-carbon nanotube-nano ferroferric oxide magnetic particles / epoxy resin wave absorbing agent: epoxy diluent phenyl glycidyl ether 2.9g, curing agent low molecular weight polyamide 1.54 g, 0.13g of antifoaming agent polyoxyethylene polyoxypropylene glyceryl ether (the material should be specified in the embodiment) and 0.43g of epoxy resi...

Embodiment 2

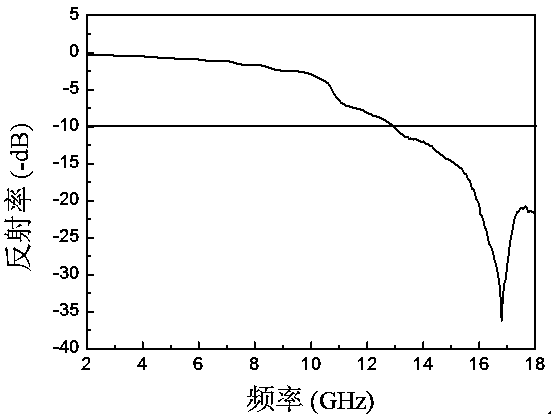

[0032] Embodiment 2: A preparation method of a wave absorbing agent with a similar multi-layer structure is carried out according to the following steps.

[0033] 1. Preparation of absorbing agent for hollow porous activated carbon fiber-carbon nanotube dielectric loss layer: with polypropylene nitrile-based hollow porous carbon fiber as the substrate, nano-Nio catalyst particles are loaded on the surface by electroplating. The electroplating time is 10 minutes, and then Wash several times with distilled water and dry. Carbon nanotubes are grown on the surface by chemical vapor deposition.

[0034]2. Preparation of polyacrylonitrile-based hollow porous carbon fiber-carbon nanotube-nano-nickel magnetic particle absorber: 0.5g of epoxy diluent 1,4-butanediol diglycidyl ether, 0.5g of curing agent, and defoamer Mix 0.053g of polyoxyethylene polyoxypropylene pentaerythritol ether and 3.95g of epoxy resin (E-54) to prepare 5g of epoxy resin solution, add 2g of nano-nickel magnetic...

Embodiment 3

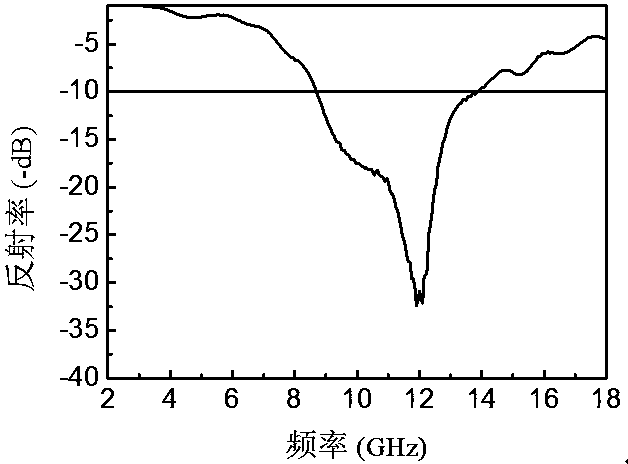

[0038] Embodiment 3: A preparation method of a wave absorbing agent with a similar multi-layer structure is carried out according to the following steps.

[0039] 1. Preparation of hollow porous activated carbon fiber-carbon nanotube dielectric loss layer absorber: use polypropylene-based carbon fiber as the matrix, and carry nano-Fe catalyst particles on its surface by electroplating. The electroplating time is 1min, and then washed with distilled water Several times, dry. Carbon nanotubes are grown on the surface by chemical vapor deposition.

[0040] 2. Preparation of polypropylene-based carbon fiber-carbon nanotube-nanocobalt magnetic particle absorber: 3.9 g of epoxy diluent polypropylene glycol diglycidyl ether, 0.75 g of modified amine curing agent, and defoaming agent polyoxyethylene Mix 0.25g of oxypropyleneamine ether and 0.1g of epoxy resin (E-54) to prepare 5g of epoxy resin solution, add 1g of nano-cobalt magnetic particles to 5g of epoxy resin solution, stir mec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical bandwidth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| optical bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com