Preparation method and application of carbon material-based nano wave absorbing agent

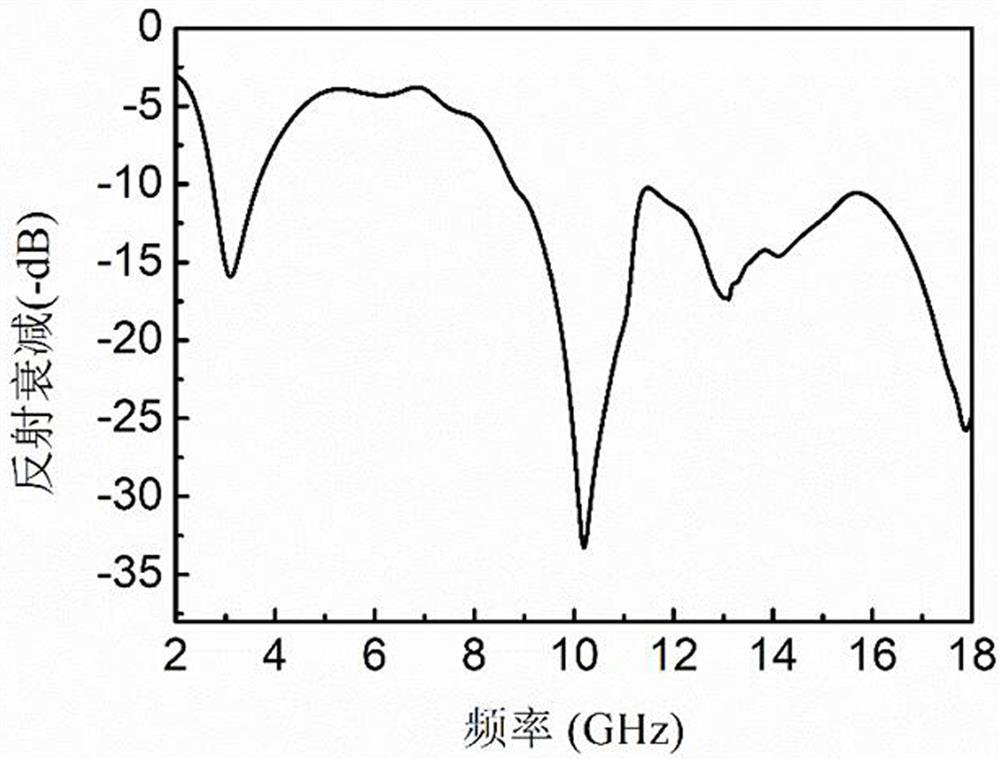

A technology of wave absorbing agent and carbon material, which is applied in the preparation and application field of nano wave absorbing agent based on carbon material, can solve the problem of narrow wave absorbing frequency band, achieve wide absorbing frequency band, strong electromagnetic wave loss capability, and broaden absorbing frequency band The effect of width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

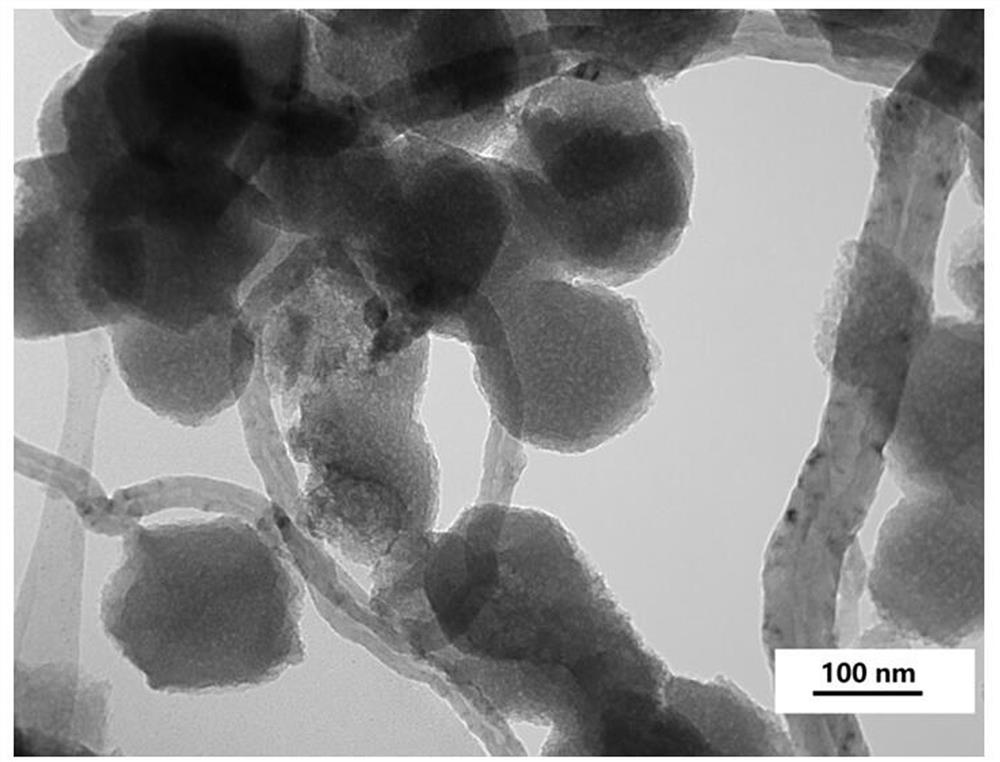

[0026] Embodiment 1: carry out according to the following steps.

[0027] (1): Preparation of dispersion A: Weigh 1 g of cobalt nitrate hexahydrate powder, disperse it in 100 ml of solvent methanol, add 20 mg of carbon nanotubes, and use a magnetic stirrer to stir at 500 r / min for 2 min. A dispersion liquid of cobalt nitrate and carbon nanotubes was prepared and set aside.

[0028] (2): Preparation of dispersion B: Weigh 1.32 g of dimethylimidazole, disperse it in 100 ml of methanol, and use a magnetic stirrer to stir at 500 r / min for 2 min to obtain a dispersion of dimethylimidazole ,spare.

[0029] (3): Add the above two dispersions A and B into an airtight container and mix them. After standing for 12 hours, the dispersion will be stratified. After filtering through a funnel with a sand core, take the purple solid substance and store it under the condition of 80 ℃. Dry and set aside.

[0030] (4): Put the purple powdery substance prepared in step (3) in a quartz boat, pl...

Embodiment 2

[0032] Embodiment 2: carry out according to the following steps.

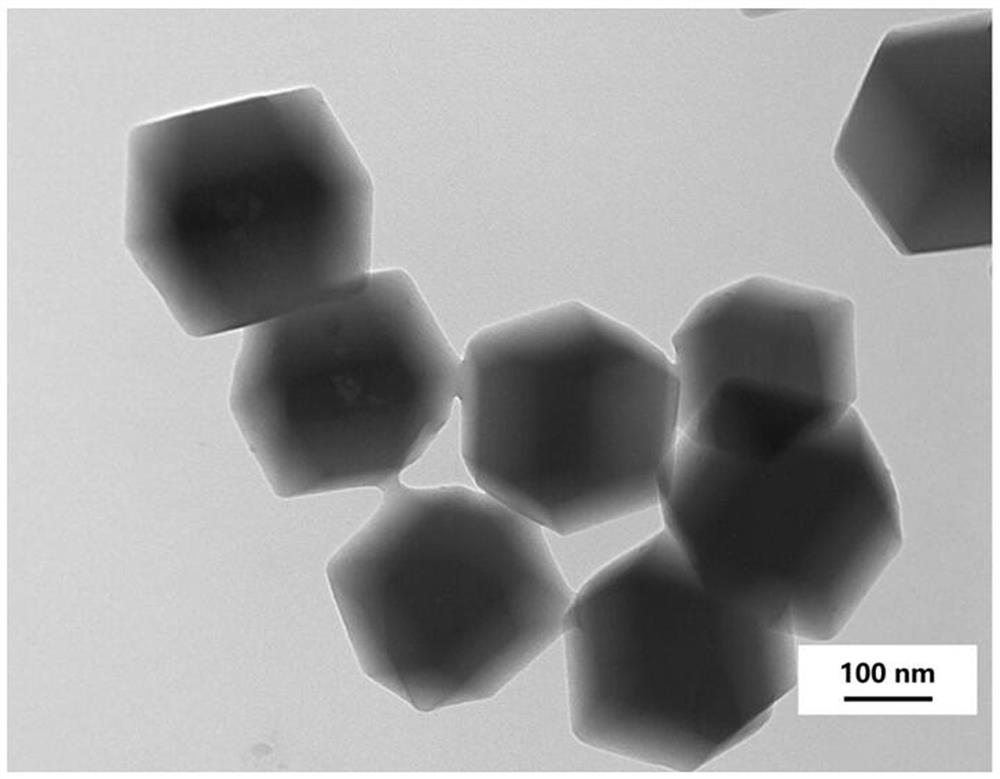

[0033] (1): Preparation of dispersion A: Weigh 1 g of cobalt nitrate hexahydrate powder, disperse it in 200 ml of solvent methanol, add 100 mg of graphene, and stir at 500 r / min for 10 min with a magnetic stirrer to prepare Obtain the dispersion liquid of cobalt nitrate and carbon nanotube, set aside.

[0034] (2): Preparation of dispersion B: Weigh 1.32 g of dimethylimidazole, disperse it in 200 ml of methanol, and use a magnetic stirrer to stir at 500 r / min for 10 min to obtain a dispersion of dimethylimidazole ,spare.

[0035] (3): Add the above two dispersions A and B into an airtight container and mix them. After standing for 12 hours, the dispersion will be stratified. After filtering through a funnel with a sand core, take the purple solid substance and store it under the condition of 80 ℃. Dry and set aside.

[0036] (4): Put the purple powdery substance prepared in step (3) in a quartz boat, place i...

Embodiment 3

[0038] Embodiment 3: carry out according to the following steps.

[0039] (1): Preparation of dispersion A: Weigh 1 g of cobalt nitrate hexahydrate powder, disperse it in 200 ml of solvent methanol, add 30 mg of graphene, and stir at 500 r / min for 5 min with a magnetic stirrer to prepare Obtain the dispersion liquid of cobalt nitrate and carbon nanotube, set aside.

[0040] (2): Preparation of dispersion B: Weigh 1.32 g of dimethylimidazole, disperse it in 200 ml of methanol, and use a magnetic stirrer to stir at 500 r / min for 5 min to obtain a dispersion of dimethylimidazole ,spare.

[0041] (3): Add the above two dispersions A and B into an airtight container and mix them. After standing for 12 hours, the dispersion will be stratified. After filtering through a funnel with a sand core, take the purple solid substance and store it under the condition of 80 ℃. Dry and set aside.

[0042] (4): Put the purple powdery substance prepared in step (3) in a quartz boat, place it in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com