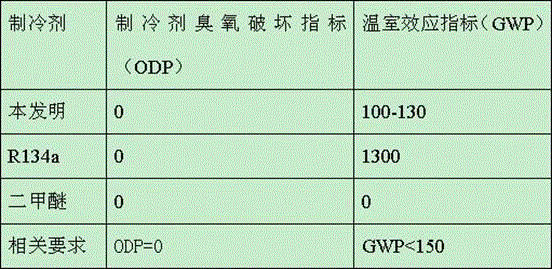

Ether-based refrigerant and preparation method thereof

A refrigerant and ether-based technology, which is applied in the field of ether-based refrigerants and their preparation, to achieve the effects of reducing dosage, slowing down the degree of flashing, and increasing charging volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

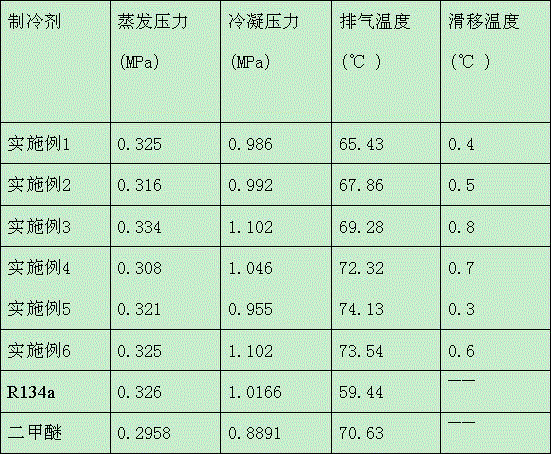

Embodiment 1

[0017] The ether-based refrigerant of this embodiment is made of the following raw materials: 80 kg of dimethyl ether, 5 kg of castor oil, 5 kg of liquid carbon dioxide, 5 kg of isobutanol, and 5 kg of trifluoroiodomethane.

[0018] The preparation method of the ether-based refrigerant in this embodiment is to physically mix the components in a liquid state according to the weight ratio.

Embodiment 2

[0020] The ether-based refrigerant of this embodiment is made from the following raw materials in parts by weight: 85 kg of dimethyl ether, 3 kg of castor oil, 2 kg of liquid carbon dioxide, 5 kg of isobutanol, and 5 kg of trifluoroiodomethane .

[0021] The preparation method of the ether-based refrigerant in this embodiment is to physically mix the components in a liquid state according to the weight ratio.

Embodiment 3

[0023] The ether-based refrigerant of this embodiment is made from the following raw materials in parts by weight: dimethyl ether 82 kg, castor oil 4 kg, liquid carbon dioxide 4 kg, isobutanol 2 kg, trifluoroiodomethane 8 kg .

[0024] The preparation method of the ether-based refrigerant in this embodiment is to physically mix the components in a liquid state according to the weight ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com