System and method for treating organic hazardous waste by combining supercritical water partial oxidation and catalytic gasification

A technology for supercritical water gasification and hazardous waste, applied in the field of hazardous waste treatment, can solve the problems of consumption of combustible gas, high heating efficiency and reaction temperature, oxidation and corrosion of the reactor, etc., to reduce external heating energy consumption, The effect of reducing oxygen consumption and reducing oxidation corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. For the experimental methods that do not specify specific conditions in the examples, usually follow the conventional conditions or the conditions suggested by the manufacturer.

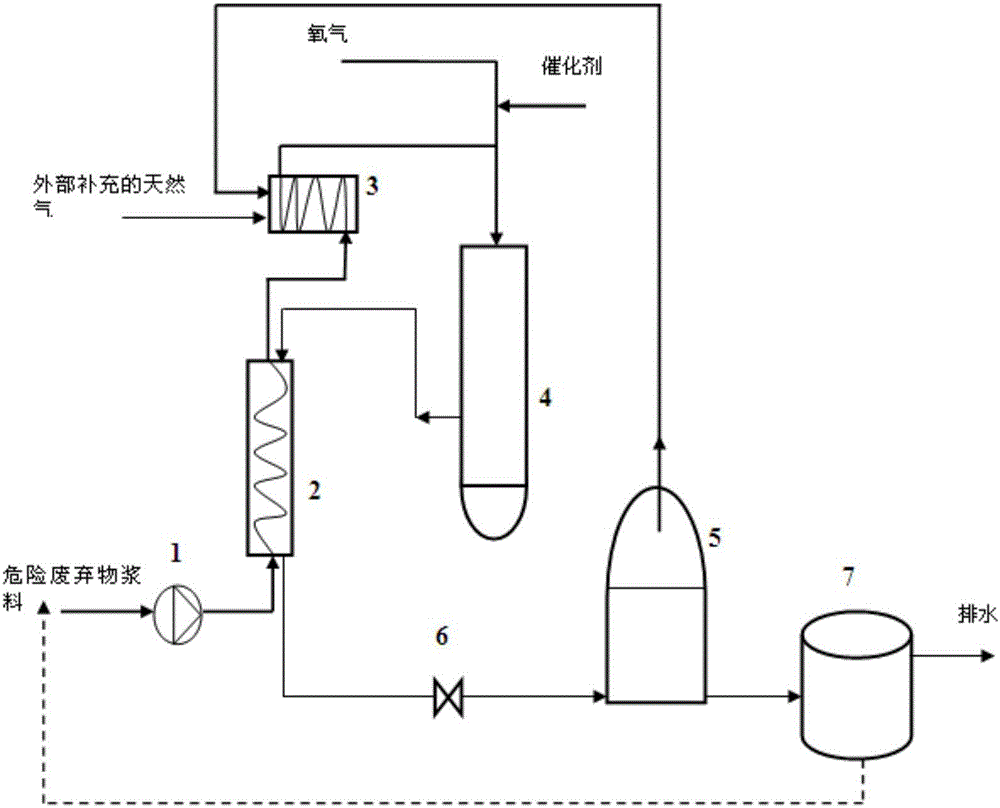

[0027] figure 1 A schematic diagram showing a system of supercritical water partial oxidation combined with catalytic gasification for treating organic hazardous waste.

[0028] The system includes a heater 3, a supercritical water gasification reactor 4, a gas-liquid separator 5, and a drainage tank 7 connected in sequence, and the organic hazardous waste is transported to the supercritical water gasification reactor 4 through the heater 3 And then produce the gas-liquid mixture, the gas-liquid mixture is delivered to the gas-liquid separator 5 for gas-liquid separation;

[0029] The system also includes a regenerator 2, the regenerator 2 includes an inlet a at the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com