Acid-resistance lactococcus lactis and application thereof

A technology of Lactococcus lactis and yogurt, applied in the direction of streptococcus/lactococcus, application, bacteria, etc., can solve the problems affecting the production efficiency of cell metabolism activity, and achieve simple and easy operation, obvious effect, good growth performance and acid resistance receptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The breeding method of embodiment 1 Lactococcus lactis (CCTCC NO:M 2016234)

[0011] Lactococcus lactis NZ9000 was used as the starting strain, cultured in GM17 medium to the logarithmic growth phase, and the concentration of the bacterial solution was adjusted to 1*10 7 Unit / CFU, the supernatant was removed after the sample was centrifuged (5000rpm; 10min), washed and resuspended with 0.85% normal saline, and repeated twice. Add an equal volume of GM17 medium containing 0.5% v / v diethyl sulfate (DES) to resuspend, 100rpm, treat at 30°C for 30 minutes, immediately wash and resuspend with 0.85% normal saline, repeat 5 times, add an equal volume of GM17 After the culture medium was resuspended, it was cultured statically at 30°C for 1.5h.

[0012] Add 1 ml of GM17 (pH 5.0) medium to 2.2 ml of 96 deep-well plates, transfer the above-mentioned post-cultivation culture solution to 96 deep-well plates with a 2% inoculation amount, and culture at 30°C for 48 hours. Investiga...

Embodiment 2

[0013] The growth performance of embodiment 2 Lactococcus lactis (CCTCC NO:M 2016234) acid stress condition

[0014] The starting strain Lactococcus lactis NZ9000 and the selected Lactococcus lactis WH102 stored in a glycerol tube at -80°C were inserted into GM17 medium at an inoculation amount of 2%, and cultured statically at 30°C for 12 hours.

[0015] Transfer the activated Lactococcus lactis NZ9000 and Lactococcus lactis WH102 to GM17 (pH 4.5) medium with an inoculum amount of 2%, and culture them statically at 30°C for 48 hours. After the fermentation, measure the bacterial concentration of the fermentation broth . Under the condition of pH 4.5, the mutant strain OD 600 The value reached 0.527, which was 4.5 times higher than before breeding. The results are shown in Table 1.

[0016] Thalline growth performance under acid stress conditions in table 1

[0017] strain Lactococcus lactis NZ9000 Lactococcus lactis WH102 OD 600 0.081 0.371

Embodiment 3

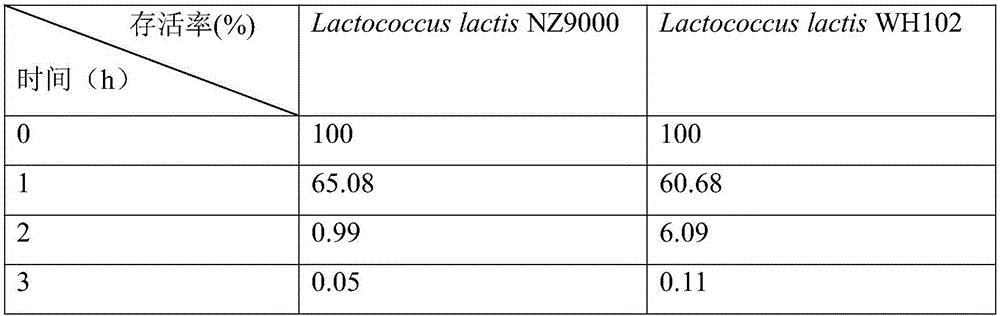

[0018] Embodiment 3 acid tolerance experiment

[0019] The starting strain Lactococcus lactis NZ9000 and the selected Lactococcus lactis WH102 stored in a glycerol tube at -80°C were inserted into GM17 medium at an inoculation amount of 2%, and cultured statically at 30°C for 12 hours.

[0020] The activated Lactococcus lactis NZ9000 and Lactococcus lactis WH102 were put into the GM17 medium with an inoculation amount of 2%, and cultured statically at 30°C until the logarithmic growth phase.

[0021] Take the cells in the logarithmic growth phase, collect the cells by centrifugation at 5000rpm for 10 minutes, wash and centrifuge the cells twice with 0.85% normal saline, resuspend in an equal volume in GM17 (pH 4.0) medium, and take samples at different times of stress, and re- Centrifuge and wash the cells twice with the same normal saline, resuspend in an equal volume of normal saline, take 100 μl of the bacterial solution and spread it on a plate after appropriate dilution, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com