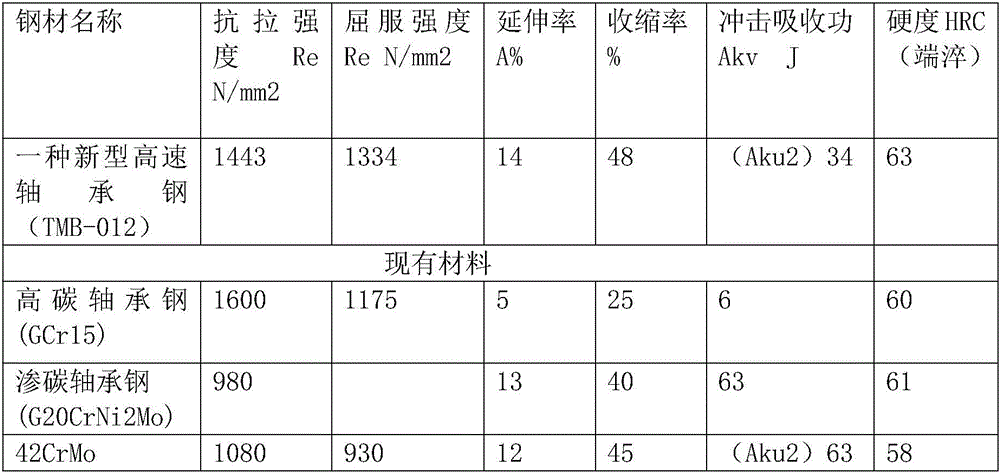

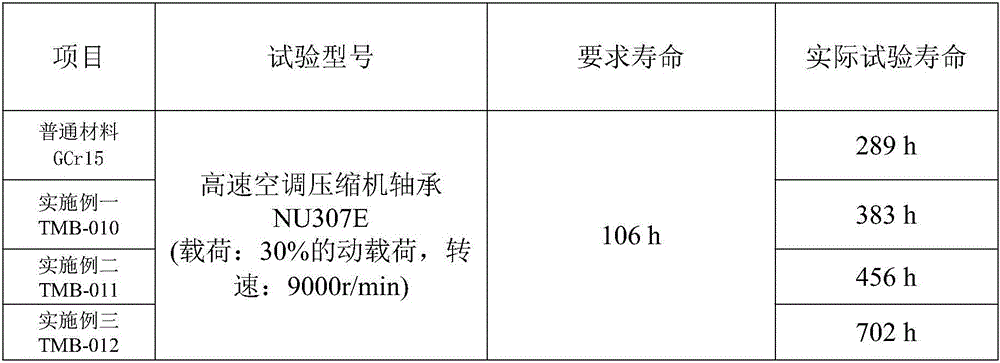

High-speed bearing steel and preparation method thereof

A high-speed bearing and steel retention technology, applied in the field of iron and steel metallurgy, can solve problems such as high price, and achieve the effects of improving hardenability, refining grains, and increasing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A high-speed bearing steel comprising the following components by weight percentage:

[0036] Carbon 0.4-0.45%

[0037] Silicon 0.9-1%

[0038] Manganese 0.95-1.05%

[0039] Phosphorus less than 0.01%

[0040] Sulfur less than 0.005%

[0041] Chromium 1.4-1.6%

[0042] Molybdenum 0.85-0.95%

[0043] Copper less than 0.1%

[0044] Aluminum 0.085-0.1%

[0045] the rest is iron;

[0046] The high-speed bearing steel has an oxygen content lower than 15PPM;

[0047] The high-speed bearing steel has a hydrogen content lower than 2PPM.

[0048] The preparation method of the above-mentioned high-speed bearing steel comprises the following steps in turn:

[0049] In the first step, the basic steel 42CrMo is initially smelted in the EBT electric furnace; after the raw materials are melted, coke powder is sprayed into the foamed slag, and the height of the slag is 550-650mm, and the slag is flowed in time and lime is added to Reduce the phosphorus content during slag ta...

Embodiment 2

[0055] A high-speed bearing steel comprising the following components by weight percentage:

[0056] Carbon 0.4-0.45%

[0057] Silicon 0.9-1%

[0058] Manganese 0.95-1.05%

[0059] Phosphorus less than 0.01%

[0060] Sulfur less than 0.005%

[0061] Chromium 1.4-1.6%

[0062] Nickel 0.4-0.5%

[0063] Molybdenum 0.85-0.95%

[0064] Copper less than 0.1%

[0065] Aluminum 0.085-0.1%

[0066] the rest is iron;

[0067] The high-speed bearing steel has an oxygen content lower than 15PPM;

[0068] The high-speed bearing steel has a hydrogen content lower than 2PPM.

[0069] Compared with Example 1, nickel element was added.

[0070]In the first step, the basic steel 42CrMo is initially smelted in the EBT electric furnace; after the raw materials are melted, coke powder is sprayed into the foamed slag, and the height of the slag is 550-650mm, and the slag is flowed in time and lime is added to Reduce the phosphorus content during slag tapping, and reduce the phosphorus t...

Embodiment 3

[0076] A high-speed bearing steel comprising the following components by weight percentage:

[0077] Carbon 0.4-0.45%

[0078] Silicon 0.9-1%

[0079] Manganese 0.95-1.05%

[0080] Phosphorus less than 0.01%

[0081] Sulfur less than 0.005%

[0082] Chromium 1.4-1.6%

[0083] Molybdenum 0.85-0.95%

[0084] Copper less than 0.1%

[0085] Aluminum 0.085-0.1%

[0086] Vanadium 0.08-0.15%

[0087] Niobium 0.08-0.15%

[0088] the rest is iron;

[0089] The high-speed bearing steel has an oxygen content lower than 15PPM;

[0090] The high-speed bearing steel has a hydrogen content lower than 2PPM.

[0091] Compared with Example 2, vanadium and niobium elements are added.

[0092] In the first step, the basic steel 42CrMo is initially smelted in the EBT electric furnace; after the raw materials are melted, coke powder is sprayed into the foamed slag, and the height of the slag is 550-650mm, and the slag is flowed in time and lime is added to Reduce the phosphorus content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com