A kind of method and application of utilizing coconut shell fiber to prepare nano-fibrils of different scales

A technology for coconut husk fibers and fibers, which is applied in the field of preparing nanofibrils of different scales by an oxidation method, can solve the problems of high efficiency, easily corroded equipment, and pollution by chemical methods, and achieves high efficiency, low corrosiveness, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

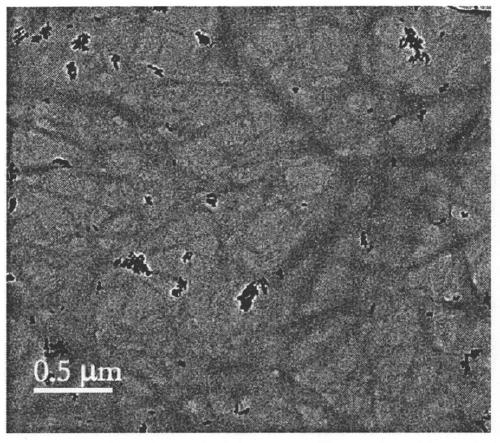

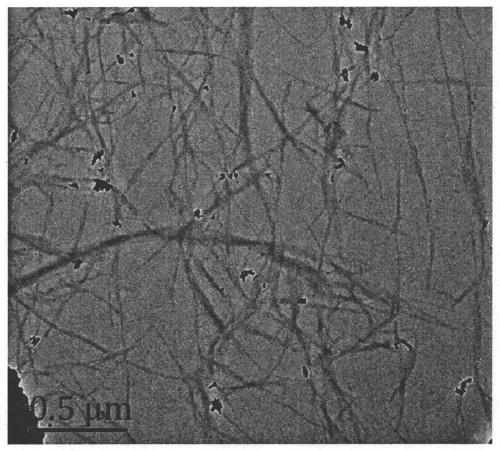

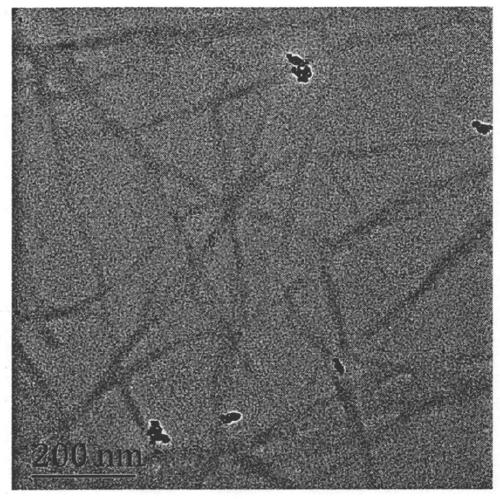

Image

Examples

Embodiment 1

[0048] A kind of method that utilizes coconut shell fiber to prepare nano-fibrils of different scales, concrete steps are:

[0049] (1) Opening and removing impurities, scouring and swelling, and cleaning to remove adherent impurities: the coconut shells are loosened by mechanical striking, rubbing and pulling, and the adhered coconut shell fibers and impurities at the roots are removed to obtain fiber clusters. The fiber mass is scoured, washed and squeezed to remove water. The specific steps of scouring, washing and squeezing to remove water include placing the fiber mass in a beaker, completely submerging it in water, and placing it in a 98°C water bath Carry out scouring and swelling for 1 hour, stir with a rotating speed of 500rpm while scouring, and use a multi-stage roller device to squeeze the fiber mass to remove water after scouring, wash with water, and then squeeze to remove water; the scouring, Washing and extruding to remove the water cycle for 4 times to remove ...

Embodiment 2

[0055] A kind of method that utilizes coconut shell fiber to prepare nano-fibrils of different scales, concrete steps are:

[0056] (1) Opening and removing impurities, scouring and swelling, and cleaning to remove adherent impurities: the coconut shells are loosened by mechanical striking, rubbing and pulling, and the adhered coconut shell fibers and impurities at the roots are removed to obtain fiber clusters. The fiber mass is scoured, washed and squeezed to remove water. The specific steps of scouring, washing and squeezing the water include placing the fiber mass in a beaker, completely submerging it in water, and placing it in a water bath at 80°C. Carry out scouring and swelling for 3 hours, stir with a rotating speed of 500rpm while scouring, and use a multi-stage roller device to squeeze the fiber mass to remove water after scouring, wash with water, and then squeeze to remove water; the scouring, Washing and extruding to remove the water cycle for 3 times to remove t...

Embodiment 3

[0062] A kind of method that utilizes coconut shell fiber to prepare nano-fibrils of different scales, concrete steps are:

[0063] (1) Opening and removing impurities, scouring and swelling, and cleaning to remove adherent impurities: the coconut shells are loosened by mechanical striking, rubbing and pulling, and the adhered coconut shell fibers and impurities at the roots are removed to obtain fiber clusters. The fiber mass is scoured, washed and squeezed to remove water. The specific steps of scouring, washing and squeezing to remove water include placing the fiber mass in a beaker, completely submerged in water, and placed in a 70°C water bath Carry out scouring and swelling for 3 hours, stir with a rotating speed of 500rpm while scouring, and use a multi-stage roller device to squeeze the fiber mass to remove water after scouring, wash with water, and then squeeze to remove water; the scouring, Washing and extruding to remove the water cycle for 3 times to remove the int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com