A kind of preparation method of wet process bright acrylic fiber

A bright, wet process technology, applied in the field of wet process bright acrylic fiber and its preparation, can solve problems such as affecting the fiber luster and fiber light transmittance, and achieve the effects of easy control, strong light transmittance and good gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

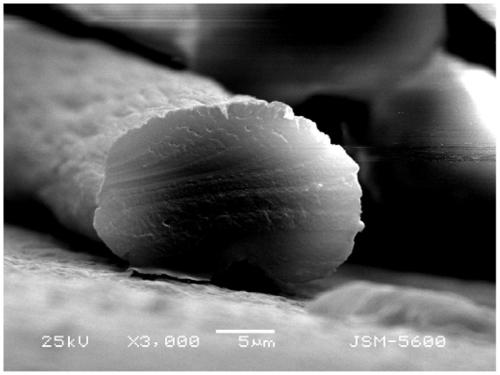

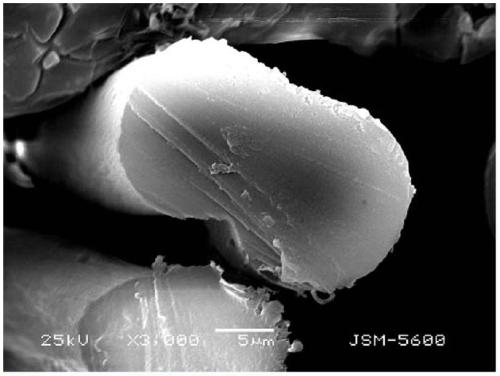

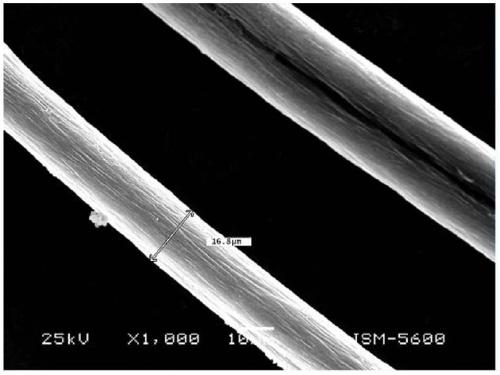

Image

Examples

Embodiment 1

[0049] (1) Preparation of polymer: Mix 94wt% acrylonitrile and 6wt% vinyl acetate, adjust the mixed concentration to 35wt%, and carry out continuous suspension in water at 58-62°C and pH 2.5 Polymerization reaction; when the intrinsic viscosity of the reaction system reaches 0.152, the chelation reaction is terminated, and the unreacted monomer is removed by a stripper, and then the salt and water are removed by washing and filtering, and it is obtained by drying after granulation Polyacrylonitrile powder polymer;

[0050] (2) Preparation of spinning stock solution: heat the polyacrylonitrile powdery polymer at 80-90°C to completely dissolve the polymer in dimethylacetamide, and then add water to obtain a spinning stock solution. The concentration of silk stock solution is 25wt%, and the addition of water is 0.5wt% of polyacrylonitrile weight;

[0051] (3) The spinning dope obtained in step (2) is spun in a coagulation bath at a pressure of 0.9 MPa and a temperature of 80 to ...

Embodiment 2

[0053] The technical process and technical parameters of this example for preparing bright acrylic fibers refer to Example 1, the difference is that the retarder is sodium borate, and the amount of sodium borate added is 1.0 wt% of the weight of polyacrylonitrile.

Embodiment 3

[0055] The process and process parameters of this example for preparing bright acrylic fibers refer to Example 1, the difference is that the retarder is zinc sulfate, and the amount of zinc sulfate added is 1.5 wt% of the weight of polyacrylonitrile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com