Silicone-oil-free agent composition for spandex dry spinning and preparation method thereof

A dry spinning, silicone-free technology, used in textiles and papermaking, fiber processing, fiber types, etc., can solve problems such as poor dyeing, poor dispersion, and difficult cleaning of fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0076] In a preferred embodiment, the nano-mesoporous silica includes one or a combination of MCM-41, MCM-48, MCM-50, SBA-15, and SBA-16.

[0077] The synthesis mechanism of the "nano mesoporous silica" is: use the structure composed of many kinds of surfactants as a template to form an ordered mesoporous material, through various physical and chemical processes (for example: microemulsion, emulsification or Sol-gel), will directly act on the surface of organic and inorganic substances, wrap the inorganic ion polymer into an orderly assembly, and finally undergo calcination and other treatments to completely remove the organic substances, retain the original framework structure, and finally form Porous ordered mesoporous materials.

[0078] In the present invention, the "mesoporous silica" can be synthesized by hydrothermal synthesis method, room temperature synthesis method, phase transformation method, microwave synthesis method, precipitation method, sol-gel method, etc. Of...

Embodiment approach 1

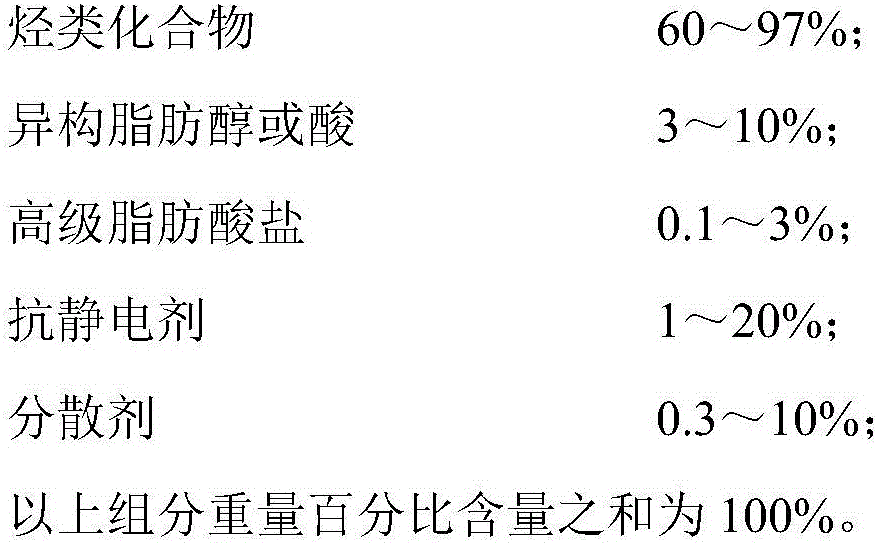

[0087] Embodiment 1: Embodiment 1 of the present invention provides a silicone-free oil composition for dry spinning of spandex, comprising at least the following components:

[0088]

[0089]

Embodiment approach 2

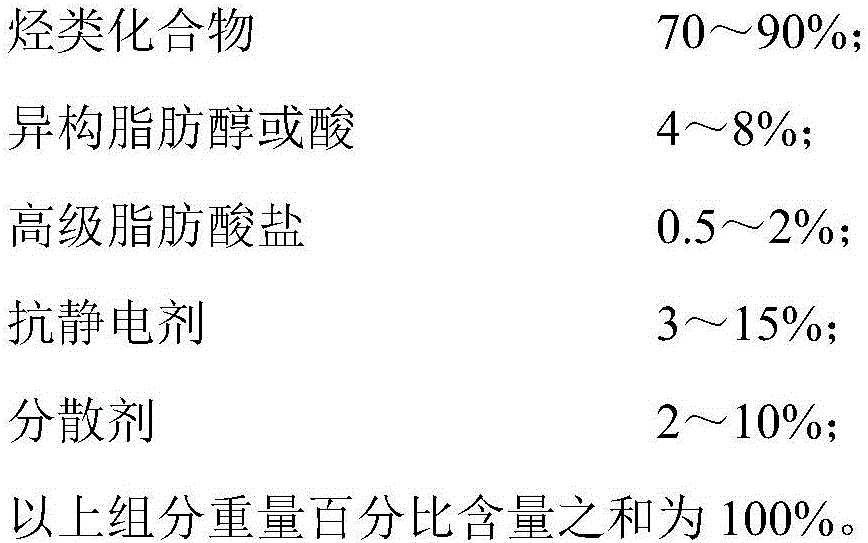

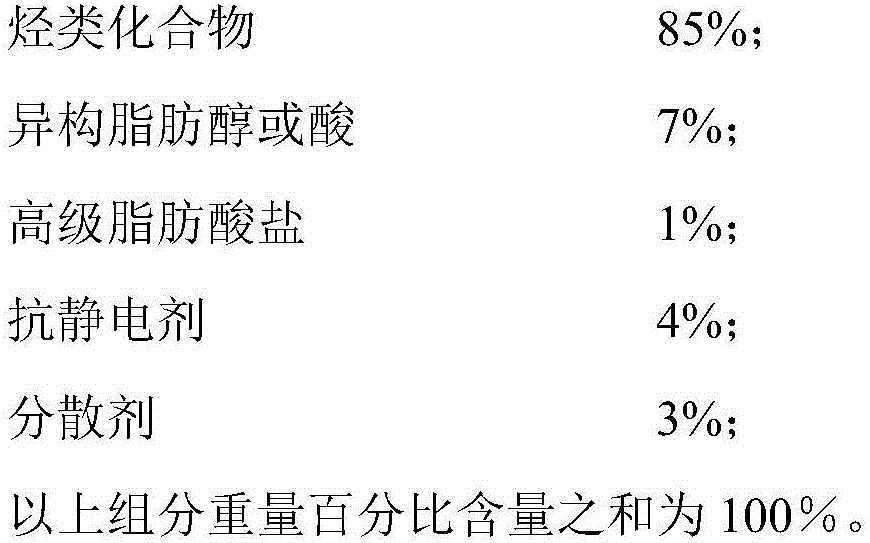

[0090] Embodiment 2: Same as Embodiment 1, the difference is that the non-silicon oil agent composition for spandex dry spinning is characterized in that it includes at least the following components:

[0091]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Kinematic viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com