Construction method of long spiral extruded cast-in-place pile based on circulating mud retaining wall

A technology of mud wall protection and construction method, which is applied in basic structure engineering, drilling equipment and methods, sheet pile walls, etc., can solve the problems of differences in experience, inability to use, and low bearing capacity of single piles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

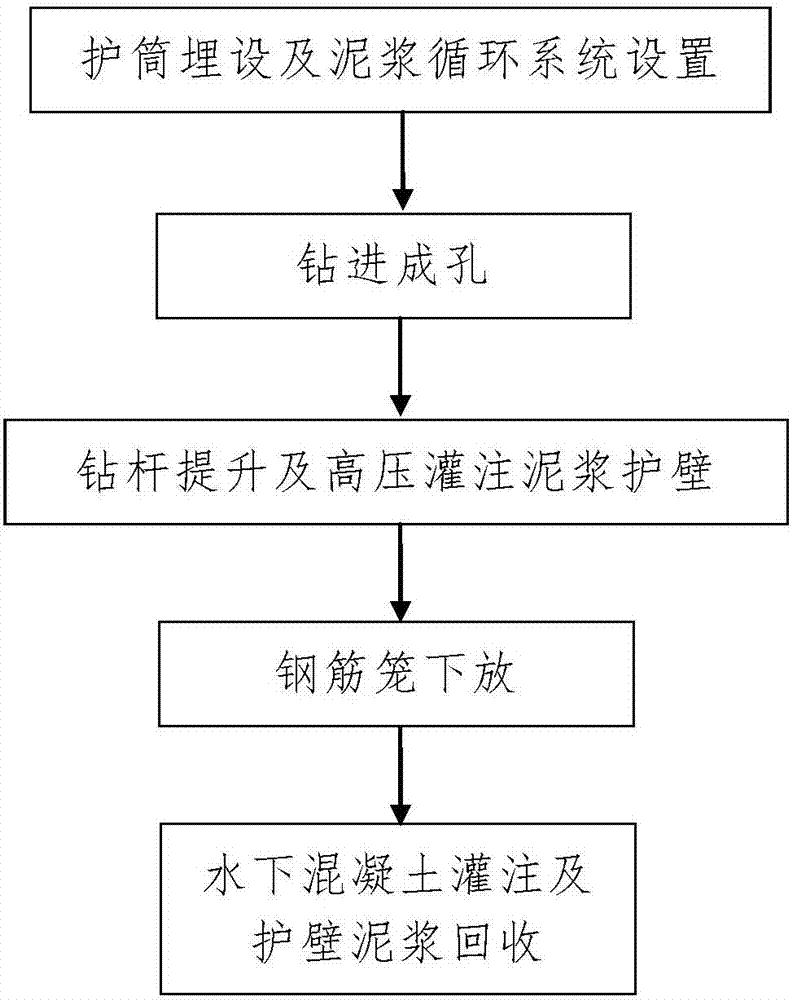

[0098] like figure 1 A construction method of long spiral extruded cast-in-place piles based on circulating mud retaining wall shown, including the following steps:

[0099] Step 1. Casing embedding and mud circulation system setting: measure and set out the pile position of the constructed long screw extruded cast-in-place pile, and bury the casing on the pile position obtained by measuring and setting out; at the same time, in the Set up a mud circulation system around the pile position of the long screw extruded cast-in-place pile;

[0100] The mud circulation system includes a slurry storage tank for storing the retaining mud and a mud pumping device for pumping the retaining mud; the upper part of the casing exposed to the ground is an exposed segment, and the exposed segment There are a plurality of overflow holes for the overflow of the retaining wall mud;

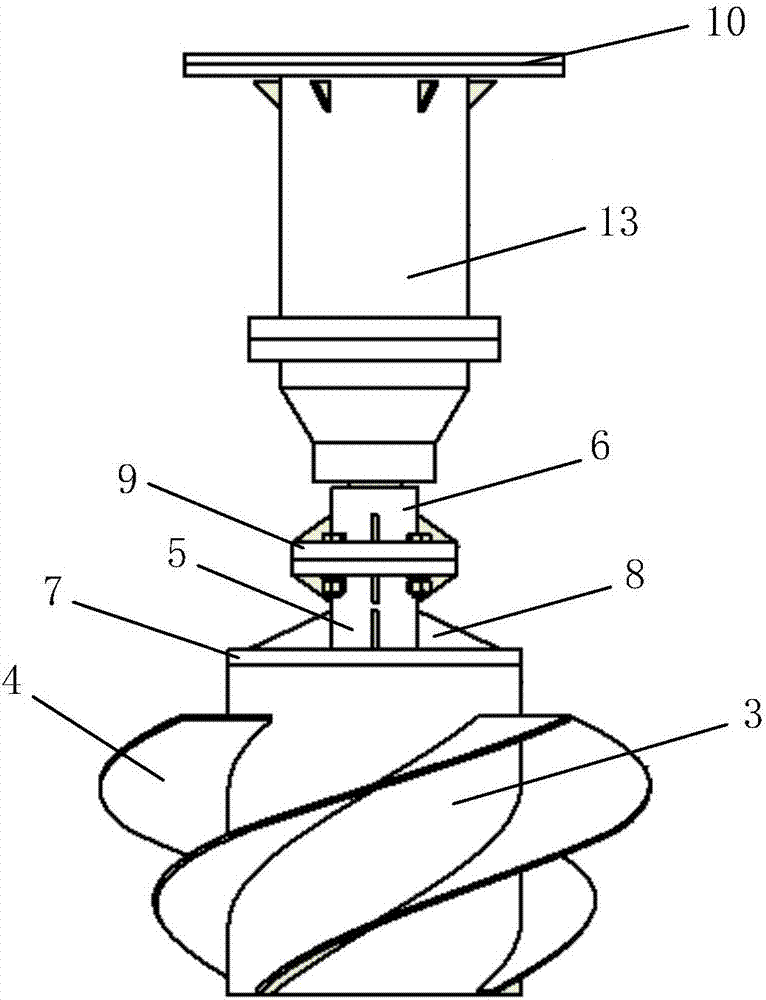

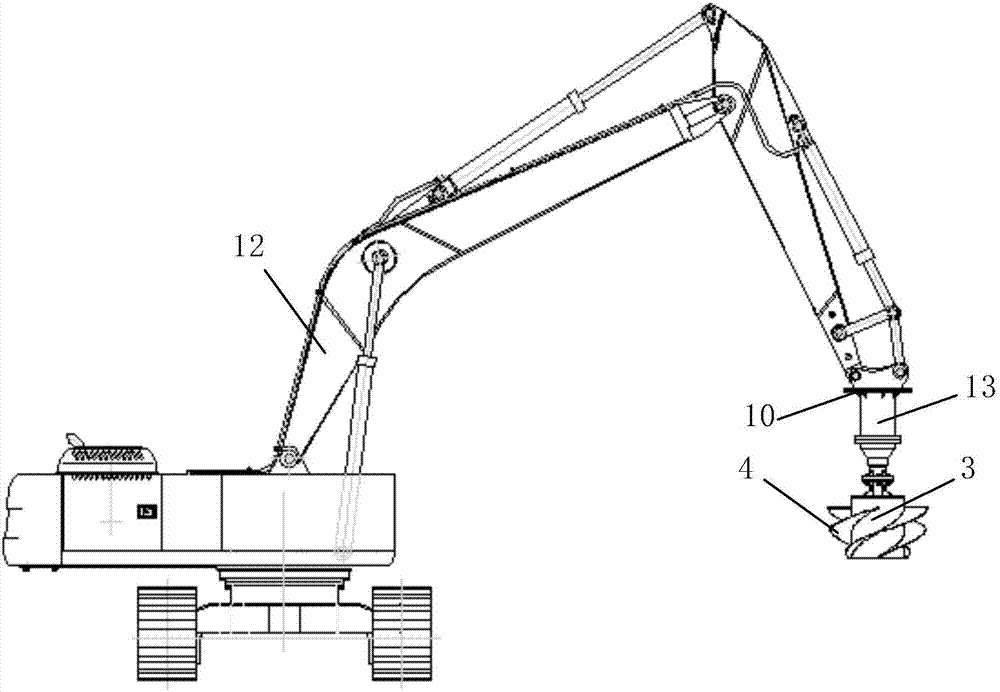

[0101] Step 2. Drilling to form a hole: Utilize the casing buried in step 1, and use a long screw pile driver t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com