A method for uncovering coal in high-gassy and low-permeability coal seams by phase transition fracturing of liquid carbon dioxide

A technology of liquid carbon dioxide and Shimen coal uncovering, which is applied in gas discharge, earthwork drilling, wellbore/well components, etc., can solve the problems of affecting gas analysis, limited effect of outburst prevention measures, and high economic cost, so as to prevent coal Combined with gas outburst, increasing the coal seam drainage rate, and realizing the effect of coal seam pressure relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

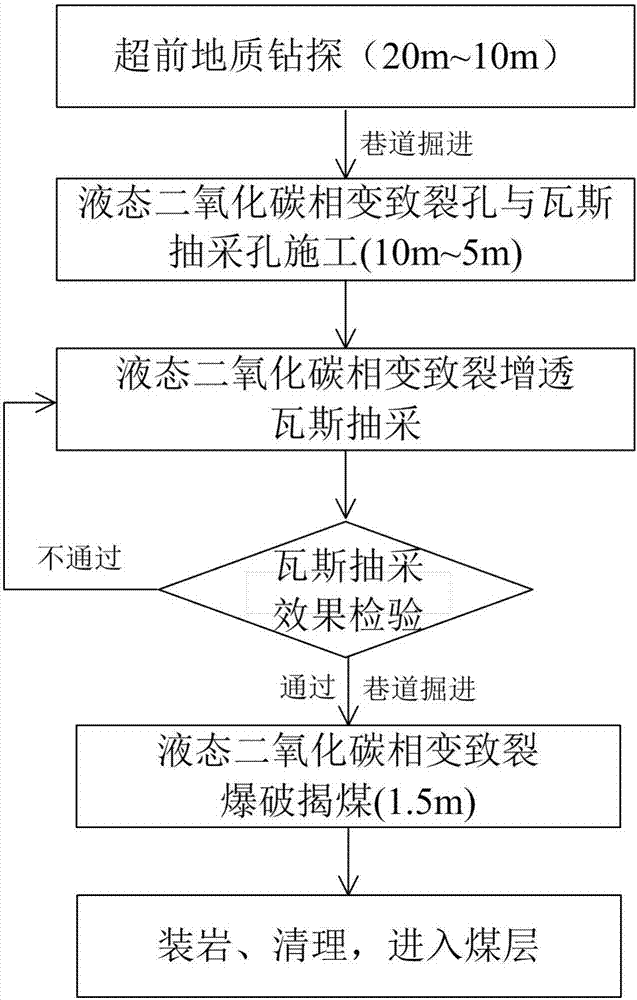

[0075] Such as figure 1 Shown, a kind of high gas low permeable coal seam liquid carbon dioxide phase transition fracturing Shimen uncovering coal method, comprises the following steps:

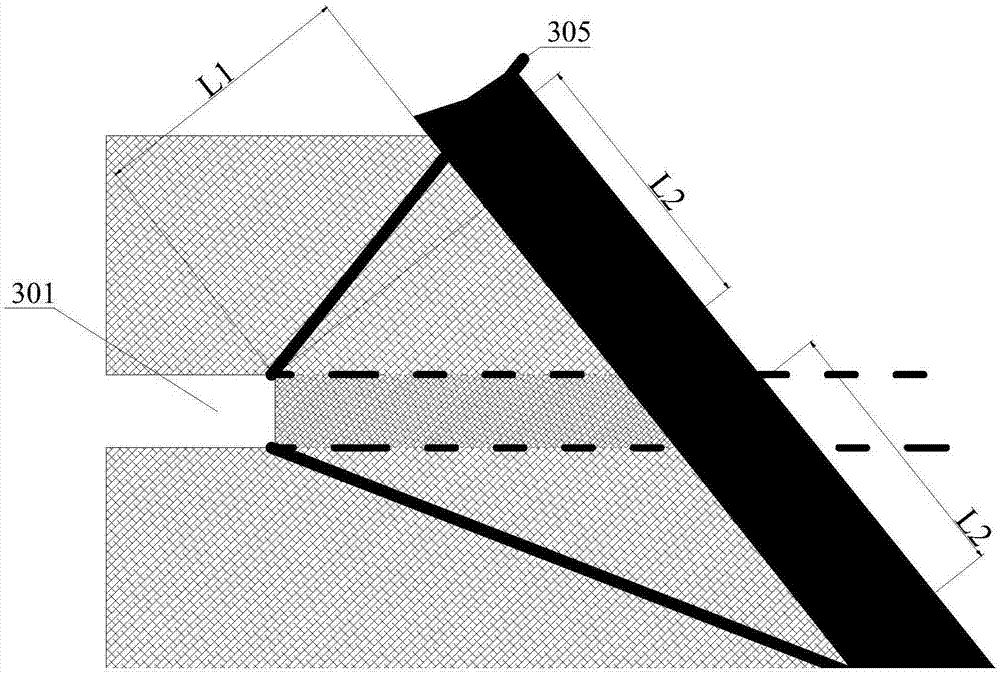

[0076] 1) Advanced geological drilling, such as figure 2 and image 3 Shown:

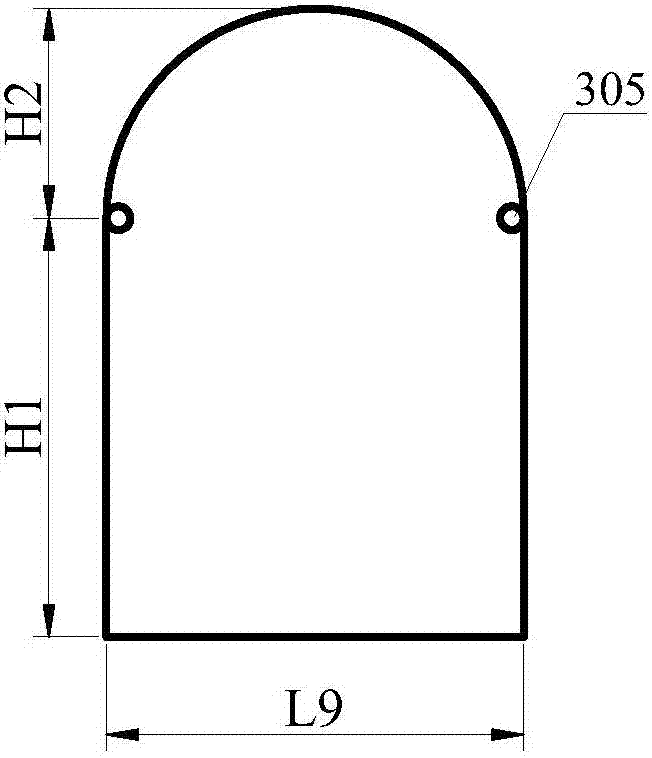

[0077] When the minimum normal distance L1 from the coal seam is 20m-10m in the excavation working face, use a diameter of 75mm or 94mm to construct two full-thickness penetrating coal seams on both sides of the excavation face 301 in the coal mining area, and Enter the front exploration core drilling 305 of no less than 0.5m on the roof or floor, and the position of the drill hole entering the coal seam is located outside the range of 12m from the distance L2 between the upper and lower sides of the coal mining roadway; record in detail whether there is a blowhole phenomenon, the inclination ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Drilling aperture | aaaaa | aaaaa |

| Critical value | aaaaa | aaaaa |

| Critical value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com