Three-dimensional electric heating cooker and three-dimensional hot pot

An electric heating furnace and electric heating technology, applied in the direction of electric heating fuel, heating method, lighting and heating equipment, etc., can solve the problems of increasing the risk of food residue carcinogens, difficult to clean pots and utensils, and unhygienic charcoal fire, etc. Harmful ingredients to human health, improve food quality and taste, fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

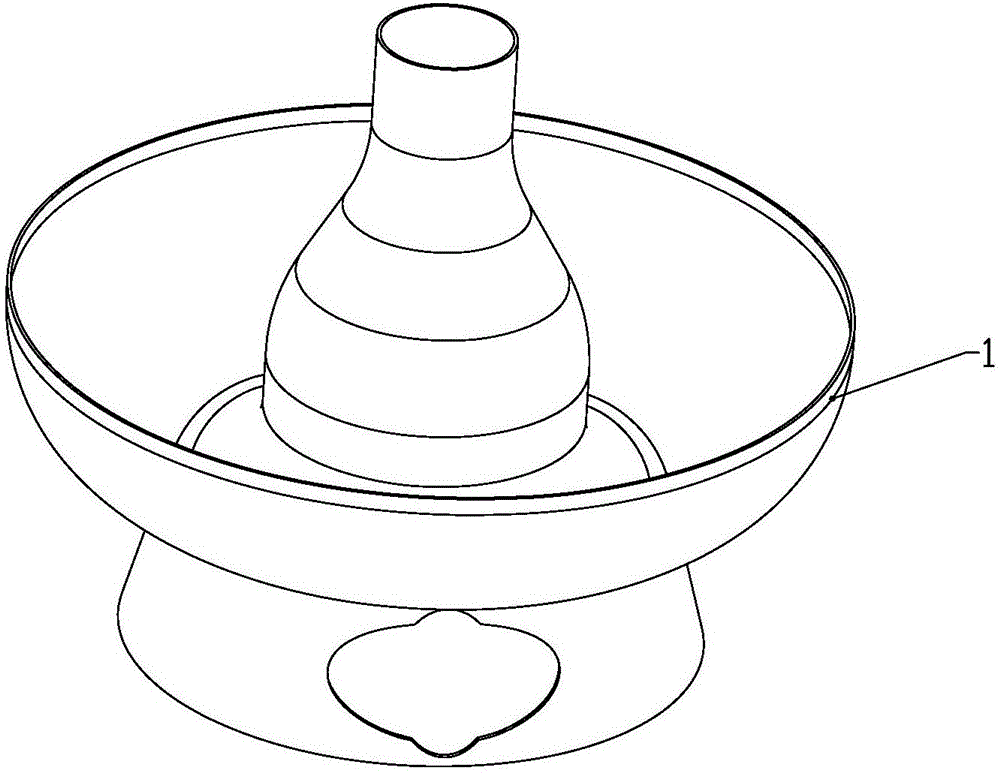

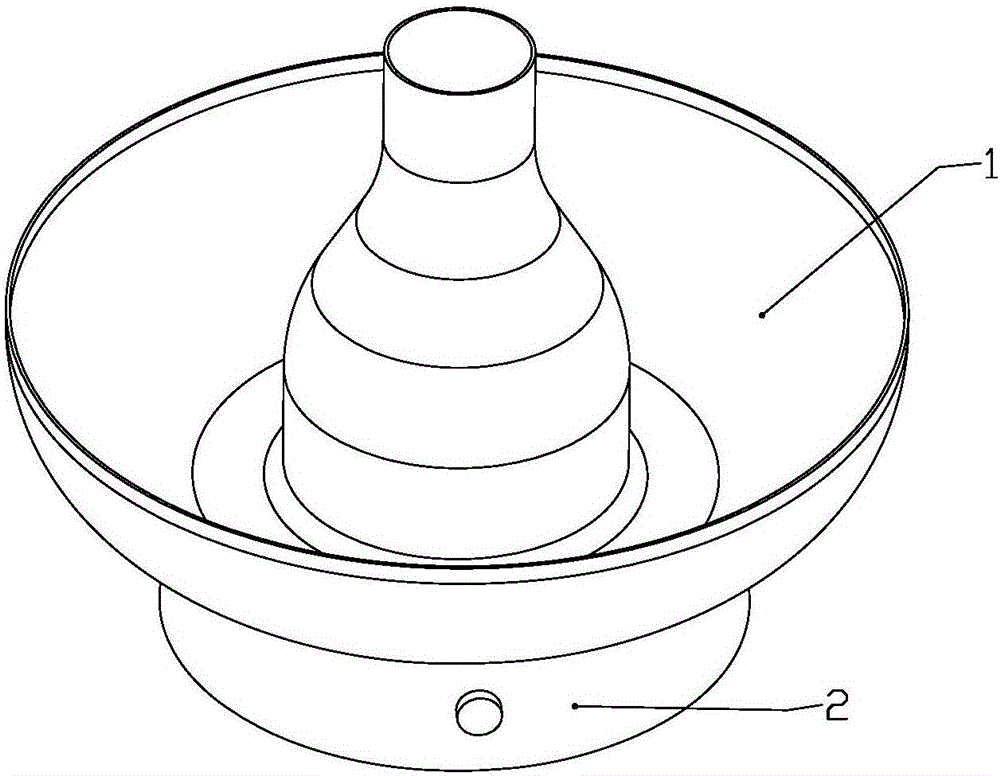

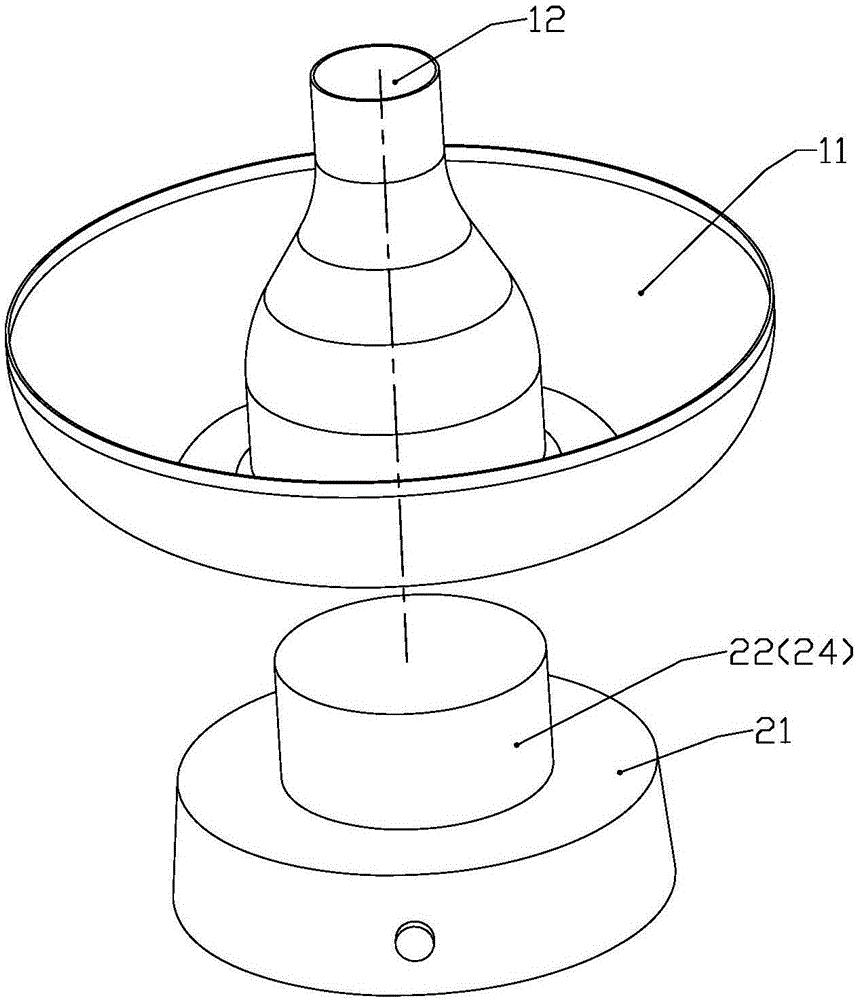

[0054] Embodiment two, such as Figure 10 , a convex-bottom hot pot, comprising a pot body 1, a pot cover and an induction cooker 2, wherein the heat dissipation mode of the electromagnetic induction coil in the induction cooker 2 is forced heat dissipation, and the cold wind rises from the middle cold air passage, and acts on the electromagnetic induction coil and then automatically The lower part is drawn away.

[0055] The pot body is a pot with a convex bottom, and the bottom of the pot body is provided with an upwardly protruding heating portion 121 , and the heating portion is in a closed shape.

[0056] As a breakthrough in the method of use, the pot rim of the above-mentioned pot body can be increased and widened for baking cakes, which is also within the protection scope of the present invention.

Embodiment 3

[0057] Embodiment three, such as Figure 11 As shown in the further improvement scheme, an auxiliary heating electromagnetic induction coil 5 is also arranged in the flat plate part of the induction cooker, which can be quickly realized through the time-sharing control of the control system, for example, in the initial stage, the auxiliary heating electromagnetic induction coil is used for auxiliary heating. Heating, when the temperature in the pot reaches the boiling temperature, it will automatically stop heating.

[0058]Of course, the above-mentioned auxiliary heating electromagnetic induction coil can also be replaced by a nano-infrared heating coil, a ceramic heating coil, or a quartz heating tube.

[0059] The above-mentioned electromagnetic induction coil is fixed by means of fasteners or fixing pieces.

[0060] A grate 3 is placed in the shabu-shabu cavity of the above-mentioned pot body for filtering impurities therein.

[0061] Above the grate is the heating area ...

Embodiment 4

[0064] As a further improvement, the nano-infrared heating ring is used as an electric heating element. Usually, the working temperature of the nano-infrared heating ring is about 400°C, and the ignition temperature of coke is between 450°C and 650°C. At this time, place coke near the nano-infrared heating ring Finally, the coke glows, simulating the effect of coke burning, which is suitable for the simulation of traditional hot pot.

[0065] In terms of specific structure, the above-mentioned protective cover is replaced with barbed wire or stainless steel wire mesh, and coke is filled inside the barbed wire, and the coke is wrapped in the nano-infrared heating ring to form a carbon pile, which is heated by the nano-infrared heating ring to simulate the above-mentioned process.

[0066] specific structure reference Figure 12 A baking pan 6 is matched with the above-mentioned induction cooker, and the inner surface of the baking pan is heated by heat radiation to form an ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com