Display method of target material metallographic structure

A technology of metallographic structure and display method, which is applied in the preparation of test samples, etc., can solve the problems of difficult control of metallographic structure corrosion rate, unclear grain boundary, and influence on the observation of metallographic structure, etc., to achieve good display effect, The effect of clear grain boundary morphology and easy observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the prior art, the method of displaying the metallographic structure of high-purity tungsten targets generally uses a mixture of nitric acid, sulfuric acid and hydrofluoric acid as an etchant, but the corrosion rate of the etchant to the metallographic structure is not easy to control, and the corrosion The grain boundary of the final sample is not clear enough, which affects the subsequent observation and analysis of the metallographic structure.

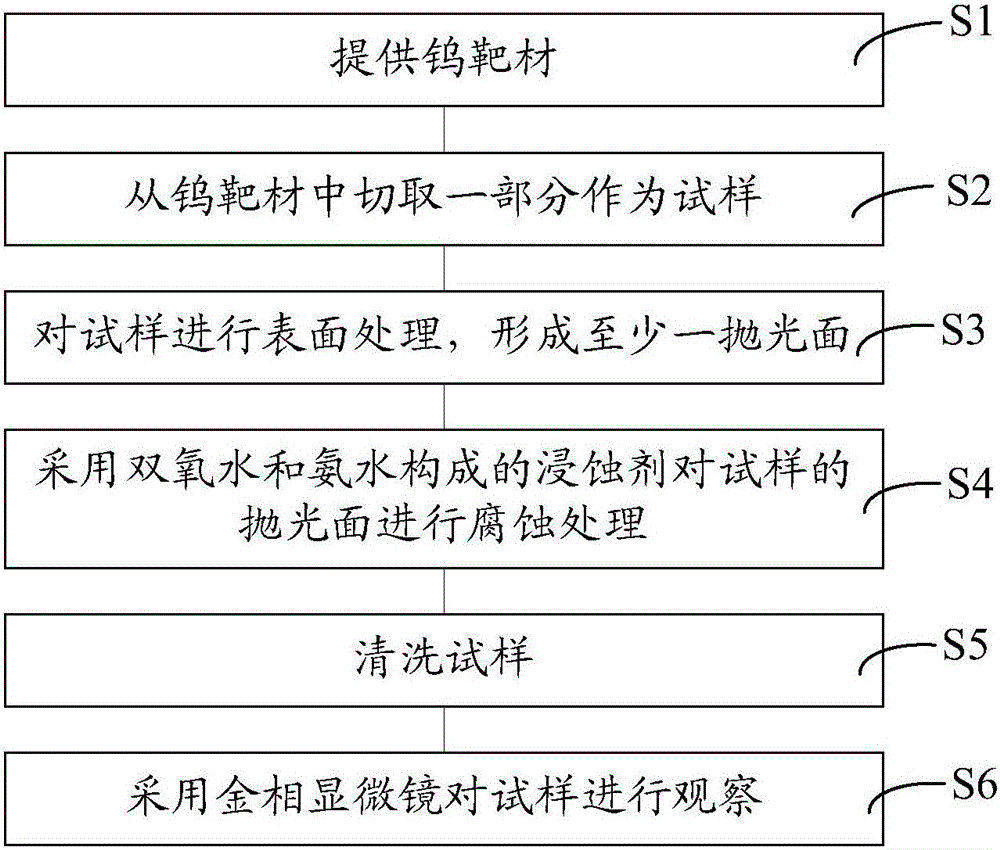

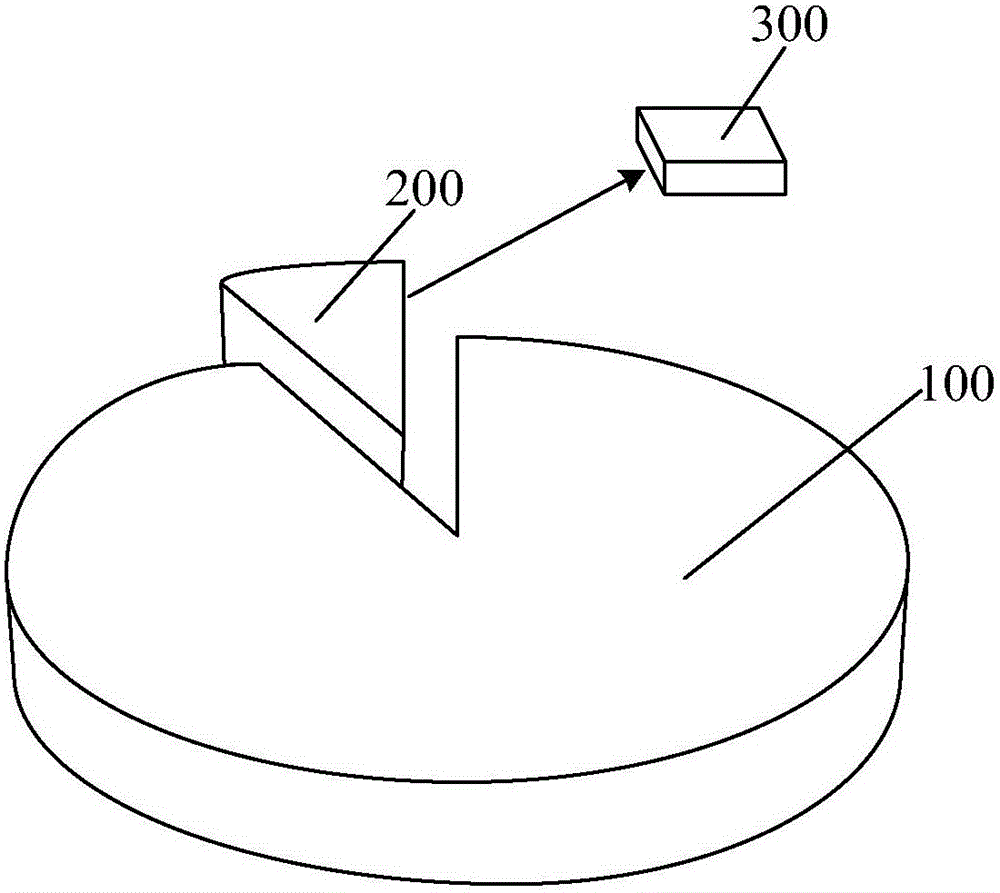

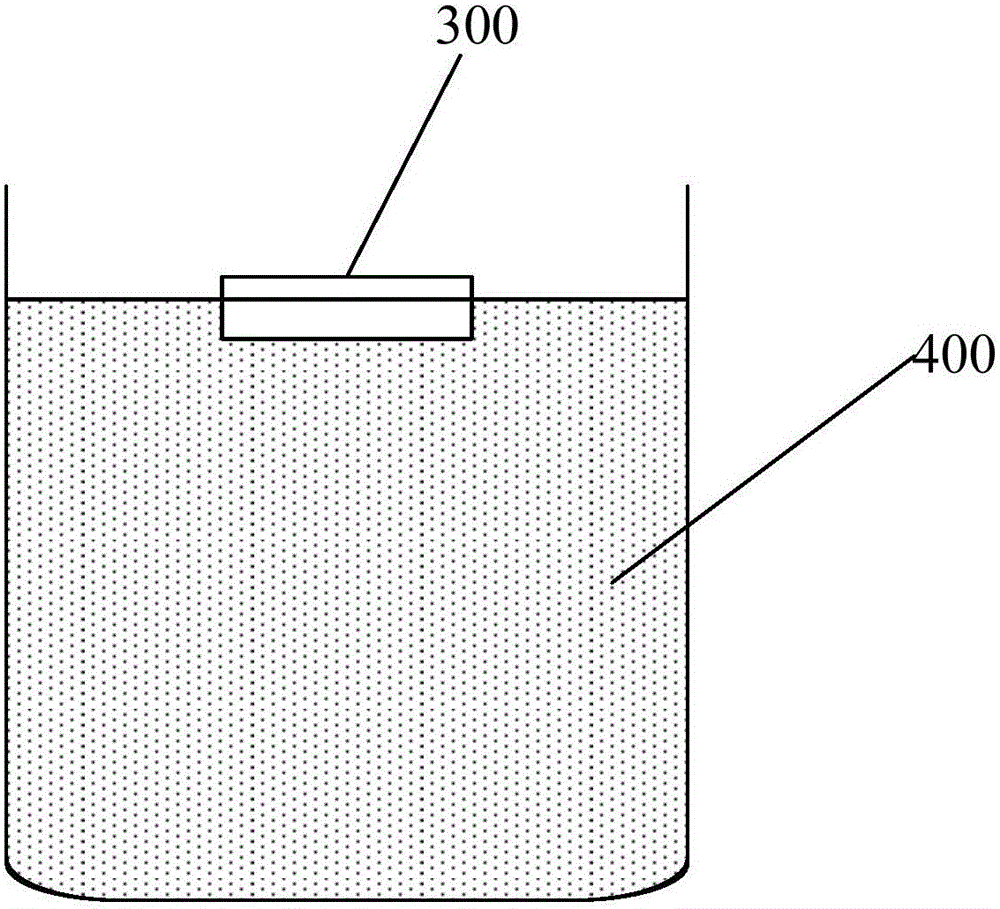

[0030] In order to solve the problem that the metallographic structure of the tungsten target is not clear in the prior art, the inventors of the present invention further optimized the corrosion process of the tungsten target sample, which specifically includes: providing a tungsten target, from the tungsten target cutting a part of the material as a sample; carrying out surface treatment on the sample to form at least one polished surface; using an etchant composed of hydrogen peroxide and ammonia water to corrode the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com