A full-process roll-to-roll preparation method of intelligent dimming film

An intelligent dimming, roll-to-roll technology, applied in optics, nonlinear optics, instruments, etc. Optical film preparation and other issues, to achieve the effect of reducing electrode cost, low production cost, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Distributed process of graphene transparent conductive film

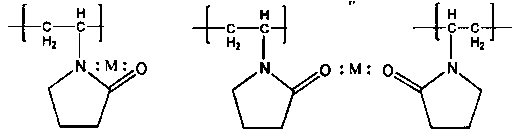

[0051] (1) Preparation of carbon-containing organic macromolecules and polymer coating fluids

[0052] A polyvinylpyrrolidone (PVP) / N,N-dimethylformamide (DMF) solution with a concentration of 1.2 g / ml was prepared.

[0053] (2) Roll-to-roll process

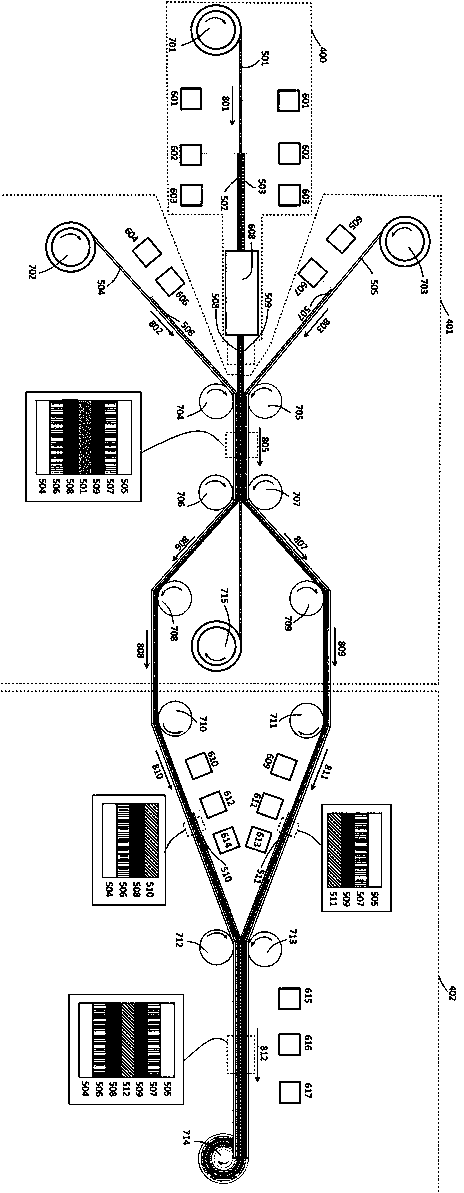

[0054] The production line is shown as Figure 4 As shown, the flexible substrate can be continuously coated or processed through the transport path. The winding roller 701 pulls the Cu foil substrate 501 with a thickness of 50 μm and a width of 0.5 m, and moves along the direction 801 from the unwinding roller 701 at a speed of 0.1 m / min. The Cu foil substrate then undergoes a series of coating and handling processes in the 801 direction.

[0055] In the pretreatment workstation 601, both sides of the Cu foil are cleaned, and then enter the coating workstation 602, where the coating workstation will coat PVP molecules on the surface of the Cu foil substrate...

Embodiment 2

[0062] Distributed process of liquid crystal smart dimming film

[0063] (1) Preparation of liquid crystal@polymer mixed coating solution

[0064] Mix epoxy resin: polyamide modifier: epichlorohydrin (small molecule to adjust the refractive index) according to the ratio of 4:1:3.2, and then add 70% of the liquid crystal mixture with the same refractive index (LC-Beijing Bayi Time and Space Liquid Crystal Technology Co., Ltd.), fully mixed and stirred at room temperature for 3 hours, that is, the mixed coating solution of liquid crystal@polymer.

[0065] (2) Roll-to-roll process

[0066] Roll to roll production line such as Figure 5 As shown, the two rolls of thin film electrodes prepared according to Example 1 will be placed on the unwinding rollers 710 and 711 respectively, and then the winding roller 714 will pull the thin film electrodes released at 710 into the release film peeling workstation 610 ; at the same time 714 will also pull the film electrode released at 711...

Embodiment 3

[0071] Integrated process of liquid crystal smart dimming film

[0072] (1) Preparation of carbon-containing organic macromolecules and polymer coating fluids

[0073] A polyvinylpyrrolidone (PVP) / N,N-dimethylformamide (DMF) solution with a concentration of 1.2 g / ml was prepared.

[0074] Electrochromic layer coating solution preparation

[0075] The PEDOT:PSS liquid purchased from Zhuhai Kaiwei was passed through a 1000-mesh filter to remove insoluble matter, and then a directly usable electrochromic layer coating liquid was formed.

[0076] Electrolyte layer coating solution preparation

[0077] Dissolve 2.4 parts by mass of lithium perchlorate in 30 parts by mass of propylene carbonate solvent, heat to dissolve, then weigh 3 parts by mass of polymethyl methacrylate into the solution, heat in an oil bath at 70°C for 8 hours , forming a viscous liquid, which is the electrolyte layer coating liquid.

[0078] Roll to Roll Process

[0079] The production line is shown as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com