T-type grooved gate MOSFET (Metal Oxide Semiconductor Field-effect Transistor)

A trench gate and deep trench technology, which is applied in the field of power semiconductors, can solve problems such as the influence of device threshold and on-resistance, and achieve the effects of preventing failure, increasing gate-source capacitance, and reducing gate-drain capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

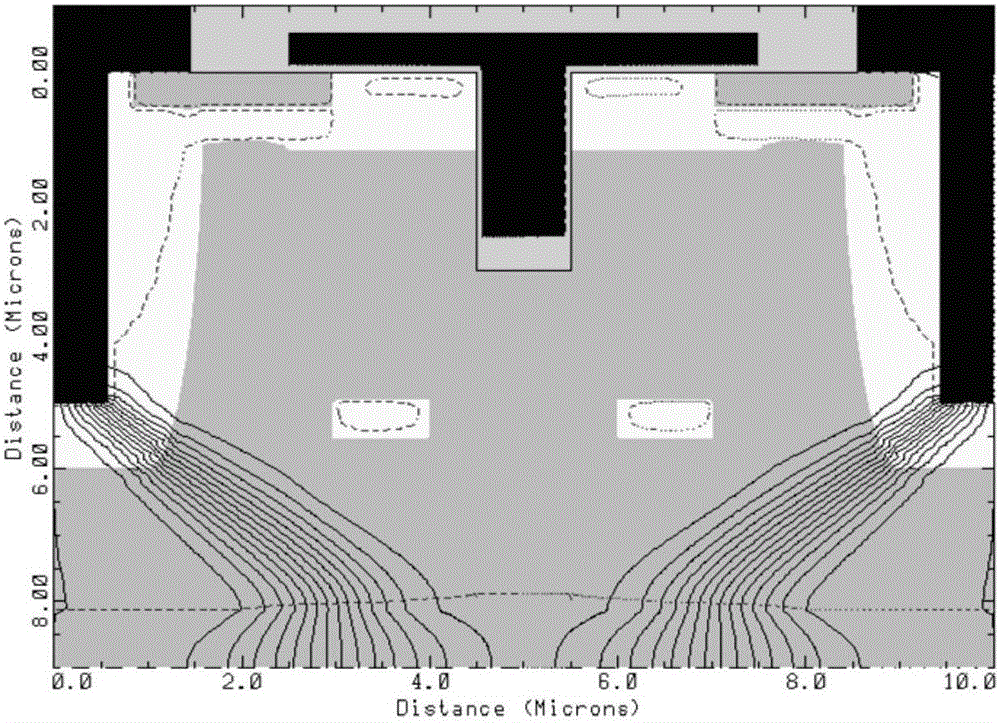

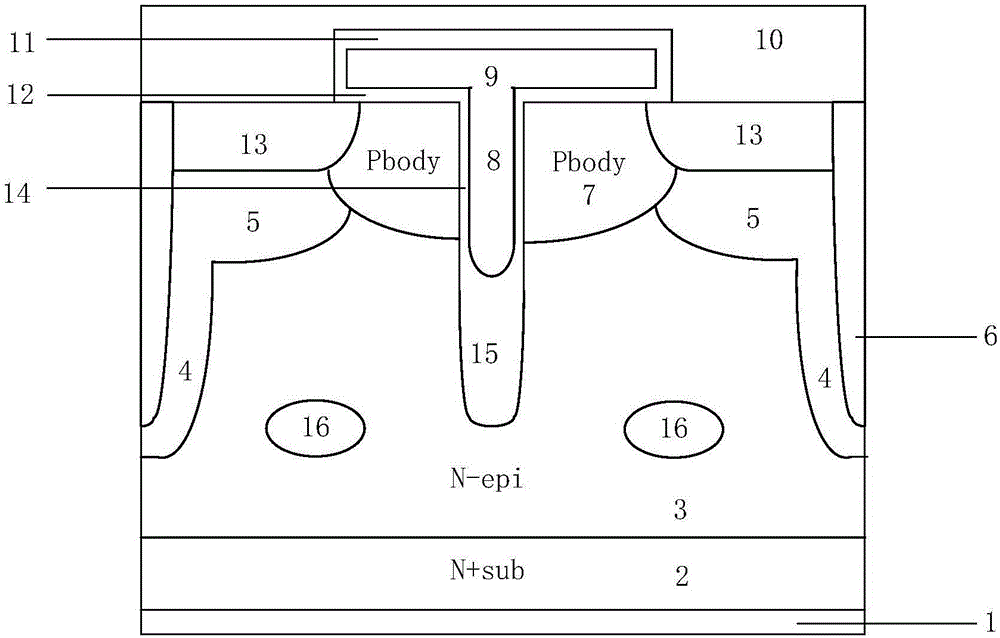

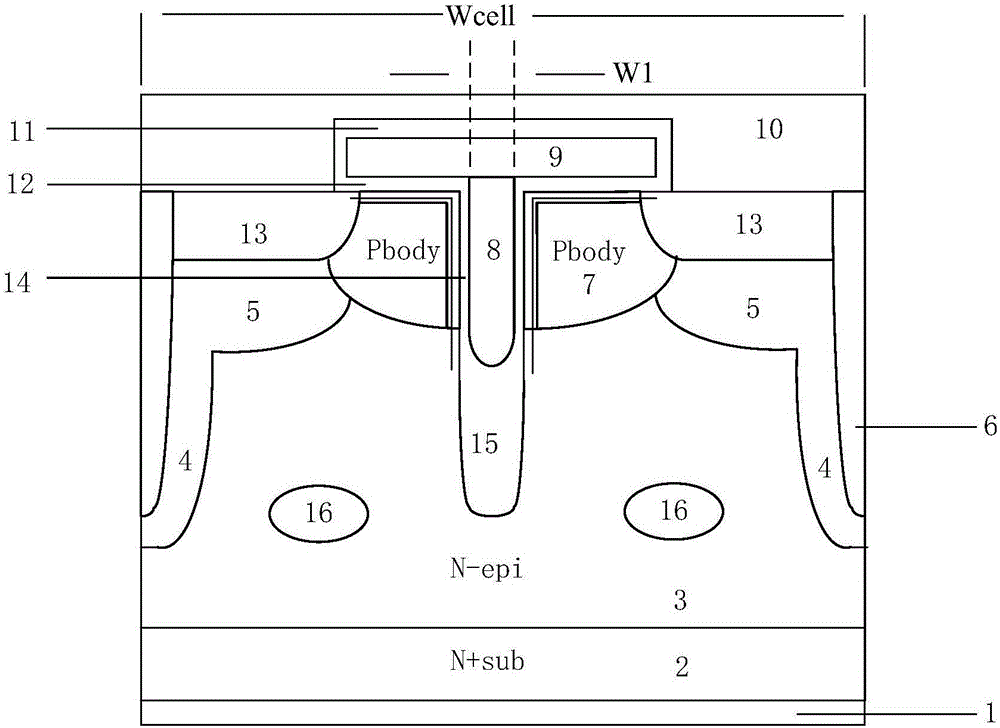

[0024] The present invention is described in detail below in conjunction with accompanying drawing

[0025] like figure 1 As shown, a T-groove gate MOSFET of the present invention includes a drain electrode 1, an N-type heavily doped single crystal silicon substrate 2, an N-epitaxial layer 3, and a source electrode 10 that are sequentially stacked from bottom to top; The middle part of the upper layer of the N-epitaxial layer 3 has a Pbody region 7, and the two sides of the N-epitaxial layer 3 have deep groove metal 6; the upper surface of the deep groove metal 6 is in contact with the source electrode 10; the Pbody region 7 is in contact with the deep The upper layer of the N- epitaxial layer 3 between the groove metal 6 has an N+ doped region 13, the upper surface of the N+ doped region 13 is in contact with the source electrode 10, and the side surfaces of the N+ doped region 13 are respectively connected to the Pbody region 7 and the deep Groove metal 6 contacts; There is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com