A process for depositing silicon nitride by tubular PECVD

A technology of silicon nitride and process, applied in metal material coating process, gaseous chemical plating, sustainable manufacturing/processing, etc., can solve the problem that graphite boats are prone to uneven heating, affect surface passivation characteristics, and hydrogen passivation effect Changes and other problems, achieve good hydrogen passivation effect, reduce self-absorption phenomenon, and slow deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The coating experiment was carried out using the process parameters in Table 1 below.

[0027] Table 1

[0028]

Embodiment 2

[0030] The coating experiment was carried out using the process parameters in Table 2 below.

[0031] Table 2

[0032]

Embodiment 3

[0034] The coating experiment was carried out using the process parameters in Table 3 below.

[0035] table 3

[0036]

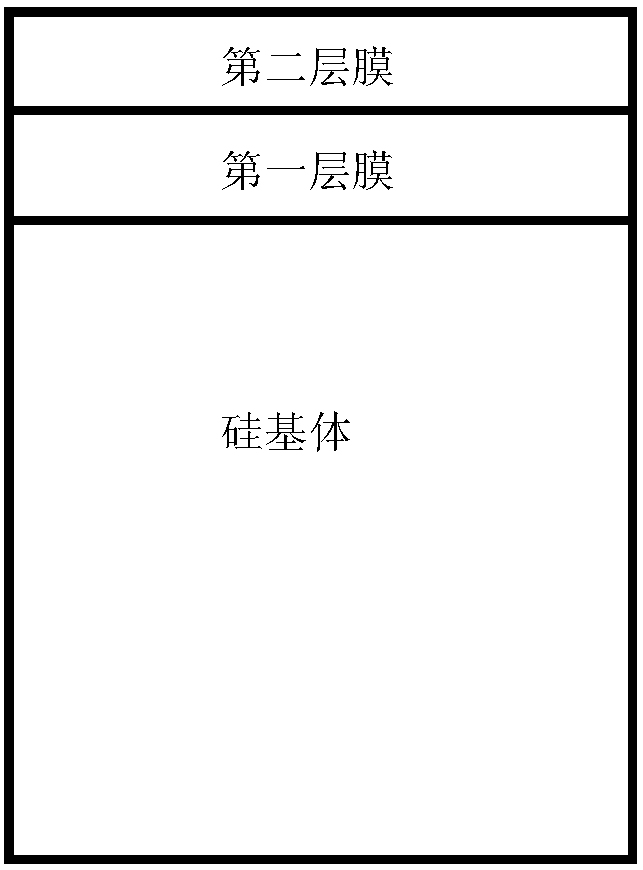

[0037] figure 1 is a schematic diagram of the structure of a bilayer membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com