Light emitting diode (LED) epitaxial layer and preparing method thereof

A technology of light-emitting diodes and epitaxial layers, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of poor crystal quality of P-type gallium nitride layers, affecting the growth efficiency of light-emitting diodes, affecting the luminous efficiency of light-emitting diodes, etc. Preparation time, excellent crystal quality, and the effect of improving luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

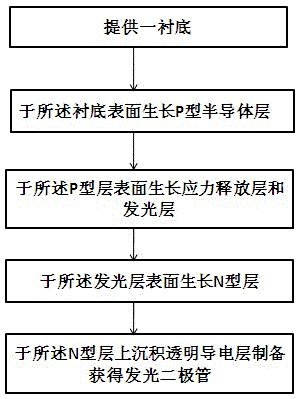

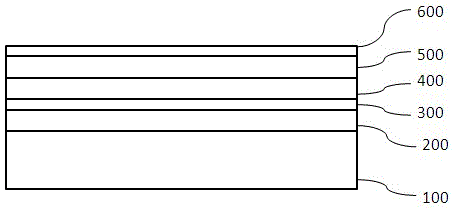

[0030] see Figure 1~2 , the method for preparing the diode epitaxial layer implemented in the present invention will be described in detail below.

[0031] First, a gallium nitride substrate 100 is provided, wherein the gallium nitride substrate 100 is a flat substrate 100 or a patterned substrate 100 .

[0032] Next, put the substrate 100 into the reaction chamber and clean the surface of the substrate 100, adjust the temperature of the chamber to 1000-1200°C, the pressure to 50-100 torr, and adopt low-speed conditions with a rate less than or equal to 0.6 μm / h To grow a P-type gallium nitride layer 200 with a thickness less than or equal to 200 angstroms. In this embodiment, the preferred substrate 100 is a flat substrate 100, and the thickness of the p-type gallium nitride layer 200 is 100-180 angstroms; where the p-type gallium nitride The doping impurity of layer 200 is preferably Mg atom, and because Mg atom has stronger lateral growth ability, so only need to grow thi...

Embodiment 2

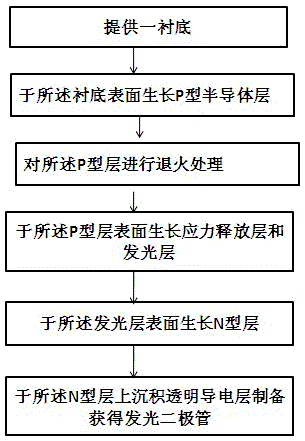

[0037] See attached figure 2 and 3The difference between this embodiment and Embodiment 1 is that this embodiment adds a high-temperature annealing step between the P-type GaN layer 200 and the stress release layer 300, specifically: stop the growth of the P-type GaN layer 200, Stabilize the chamber temperature above 950°C, and perform high-temperature annealing treatment on the P-type GaN layer. The preferred annealing temperature is 950-1100°C, and the annealing time is 1-5 minutes. Use this high-temperature treatment step to activate the P-type gallium nitride layer. The gallium layer is doped with impurities to further increase the impurity concentration entering the light-emitting layer 400 and enhance the luminous efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com