Iron carbon-based composite porous material catalyst and preparation method and application thereof

A technology for porous materials and catalysts, which is applied in the field of iron-carbon-based composite porous material catalysts and their preparation, can solve the problems of fast deactivation of catalysts, etc., and achieves the advantages of simple and easy synthesis process, prevention of roasting and agglomeration, and good support and isolation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides the preparation method of above-mentioned catalyst, and this method comprises the following steps:

[0033] (1) dissolving iron source and carbon source in an organic solvent to carry out one or more hydrothermal synthesis reactions;

[0034] (2) centrifuging the product obtained in step (1), and then drying the product after centrifuging;

[0035] (3) high-temperature carbonization of the product obtained in step (2);

[0036] Wherein, the iron source contains Fe and optional M, and M is one or more of Mn, K, Na, S, Cu and Zn.

[0037] According to the present invention, wherein, in step (1), the iron source and the carbon source are dissolved in an organic solvent to carry out one or more hydrothermal synthesis reactions, specifically, in the present invention, when the iron source only contains When iron is a metal element, the iron source and carbon source are dissolved in an organic solvent to carry out a hydrothermal synthesis...

Embodiment 1

[0051] This example is used to illustrate the preparation method of the iron-carbon based composite porous material catalyst according to the present invention.

[0052] FeCl 3 ·6H 2 O (0.374g), terephthalic acid (0.230g) were dissolved in N,N-dimethylformamide DMF (50mL) solvent, stirred at a stirring rate of 800 rpm until the solution became clear, and then The mixed solution was transferred to a hydrothermal kettle, and then the hydrothermal kettle was put into an oven, and the hydrothermal synthesis reaction was carried out at a temperature of 120° C. for 3 days;

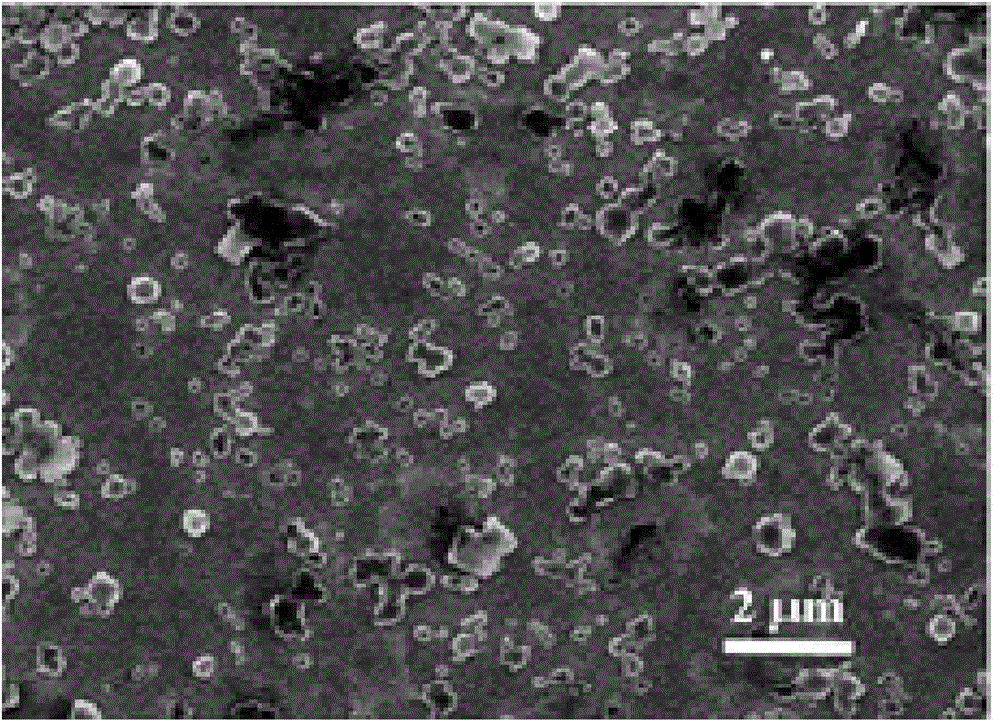

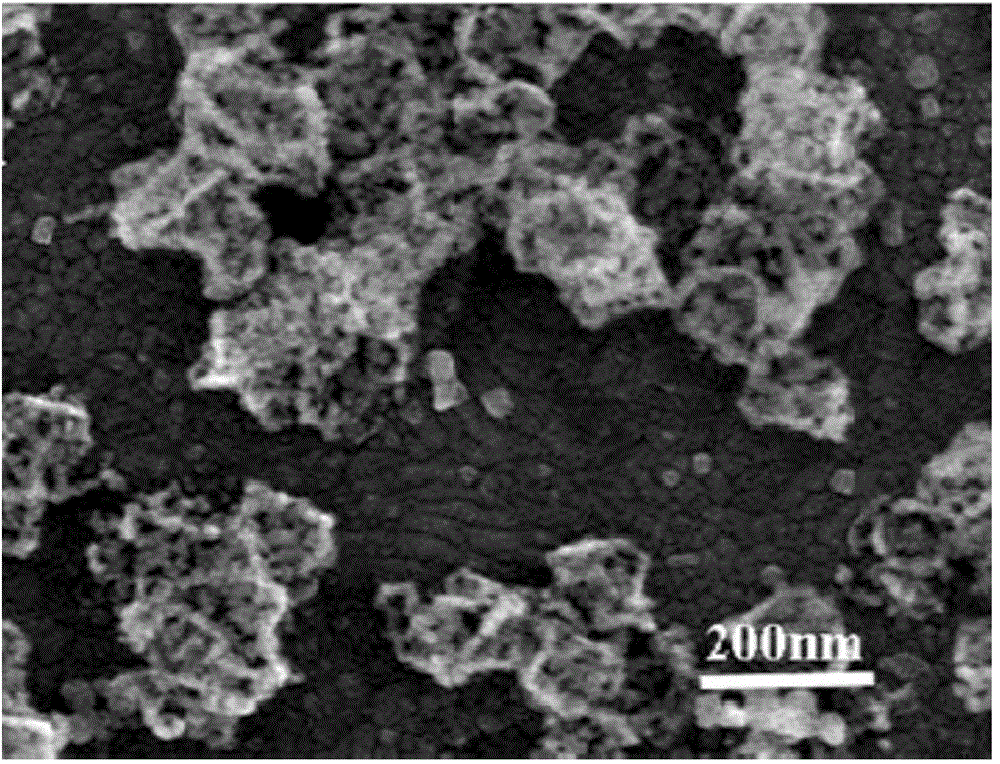

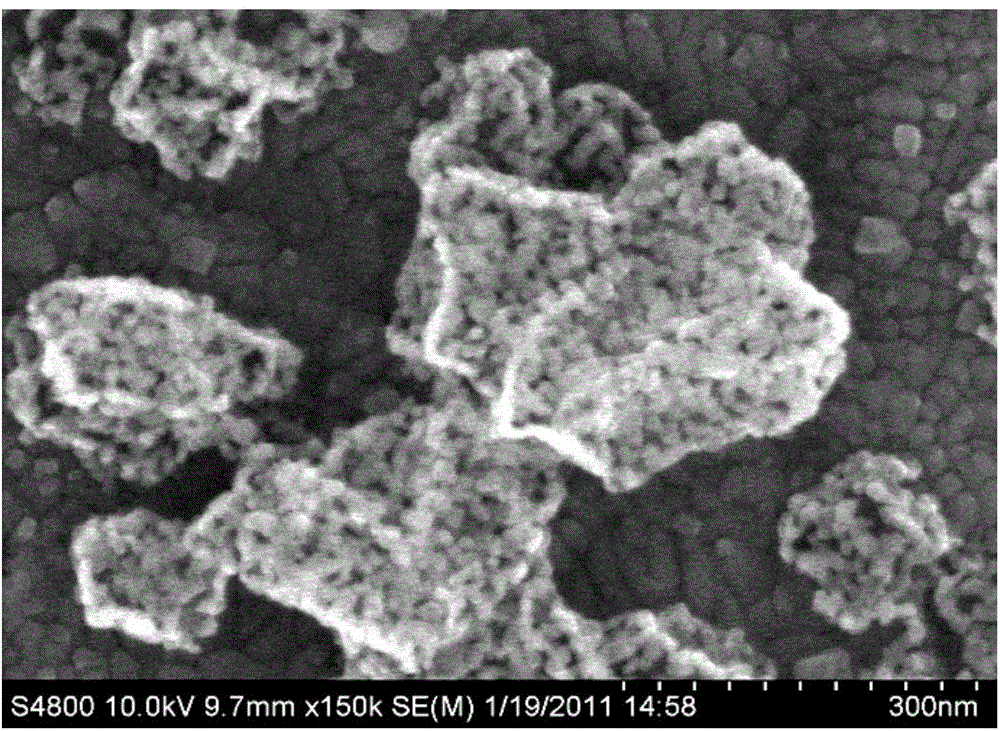

[0053] After the reaction, the hydrothermal kettle was naturally cooled to room temperature, and the product after the hydrothermal synthesis reaction was centrifuged, then washed and filtered with DMF solvent and ethanol, and then dried in a vacuum oven at a temperature of 80°C for 12 hours; the result was metal Organic framework materials, the SEM photos of which are as follows figure 1 As shown, it can be ...

Embodiment 2

[0059] This example is used to illustrate the preparation method of the iron-carbon based composite porous material catalyst according to the present invention.

[0060] FeCl 3 ·6H 2 O (0.804g), Mn (NO 3 ) 2 ·6H 2 O (0.403g), terephthalic acid (H 2 bdc; 0.752 g) was dissolved in DMF (10 mL) solvent and stirred at a stirring rate of 1000 rpm until the solution became clear. Then add NaOH solution (0.4mol / L, 10mL) and continue to stir for 15min, then transfer the mixed solution to a hydrothermal kettle, then put the hydrothermal kettle into an oven, and carry out the hydrothermal synthesis reaction at a temperature of 100°C 15 hours;

[0061] After the reaction, the hydrothermal kettle was naturally cooled to room temperature, and the product after the hydrothermal synthesis reaction was centrifuged, then washed and filtered with DMF solvent, and then dried in a vacuum oven at 70°C for 12 hours; further KOH (0.2g ) was dissolved in 50ml of deionized water, the above cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com