Surface sealing agent and use method thereof

A sealing agent and surfactant technology, applied in the field of surface treatment agents, can solve the problems of expansion in the thickness direction, little effect, affecting processing, etc., achieve excellent anti-expansion performance, solve edge expansion and mildew, and good dispersibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

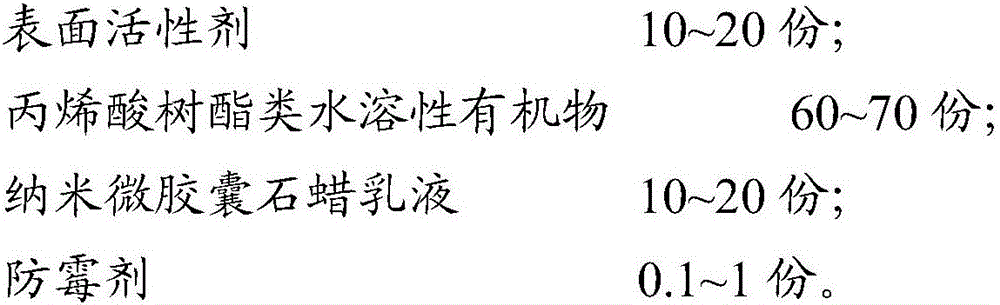

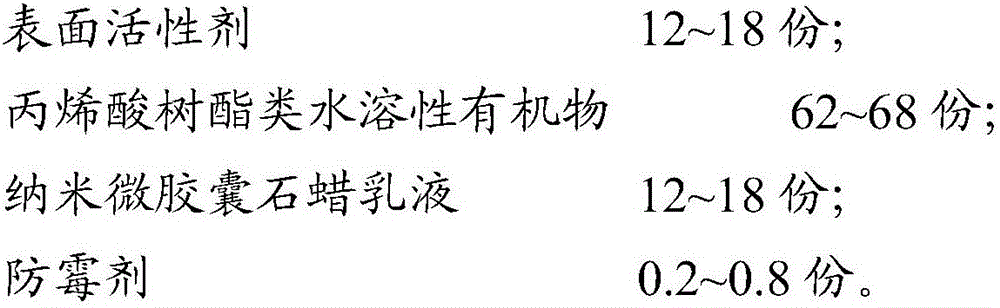

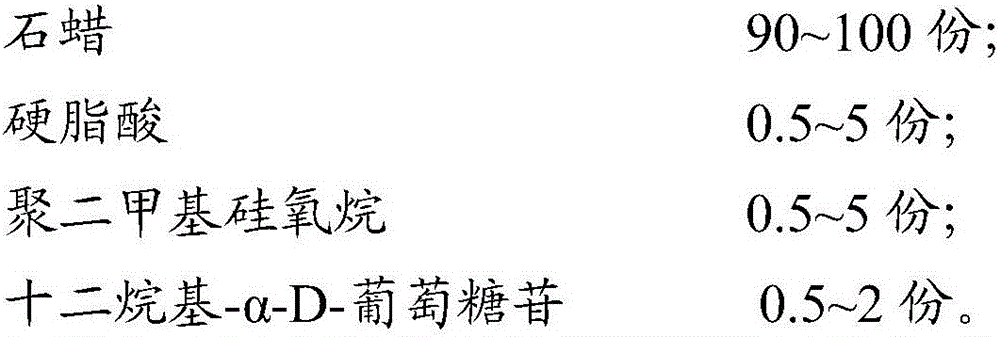

Method used

Image

Examples

preparation example Construction

[0040] The present invention has no special requirements on the preparation method of the surface sealing agent, and the surface active agent, acrylic resin water-soluble organic matter, nano-microcapsule paraffin wax emulsion and antifungal agent can be mixed in any order.

[0041] The surface sealing agent obtained in the present invention is a milky white liquid with a pH value of 7-8.

[0042] The invention also provides a method for using the surface sealing agent, which comprises coating the surface sealing agent on the surface to be treated and drying it.

[0043] The present invention has no special requirements on the specific method of finishing, which may be hand coating, dip coating or brush coating. In the present invention, the coating dosage of the surface sealing agent is preferably 300-400 g / m 2 , more preferably 320-380g / m 2 , most preferably 340-360g / m 2 .

[0044] In the present invention, the drying temperature is preferably 60-100°C, more preferably 7...

Embodiment 1

[0048] Mix 10 parts of surfactant, 60 parts of acrylic resin water-soluble organic matter, 20 parts of nano-capsule paraffin wax emulsion and 1 part of antifungal agent, and paint on the fiberboard with a brushing amount of 400g / m 2 . The painted fiberboard was dried at 60° C. for 3 minutes.

[0049]In the present invention, the dried fiberboards in Example 1 and the fiberboards coated with commercially available sealant #1 and commercially available sealant #2 were soaked in water for four weeks at room temperature, and the thicknesses of the edges of the three boards were tracked. The detailed expansion rate is shown in Table 1. The commercially available sealant #1 is Black Gold Steel (batch number 20160419), and the commercially available sealant #2 is Honglian (20160423).

[0050] Table 1 Example 1 provides surface sealant and commercially available sealant to handle the immersion expansion rate of fiberboard

[0051] Type of sealant one day a week two w...

Embodiment 2

[0063] Mix 20 parts of surfactant, 70 parts of acrylic resin water-soluble organic matter, 10 parts of nano-microcapsule paraffin wax emulsion and 0.5 part of antifungal agent, and paint on the blockboard with a brushing amount of 300g / m 2 . The painted fiberboard was dried at 100° C. for 1 minute.

[0064] The test is carried out according to the experimental method of the example, and the test result shows that the expansion rate of the fiberboard treated with the surface sealant provided by Example 2 is 0.41% after four weeks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com