Cork pad production technology

A production process and cork technology, applied in the direction of cork machining, wood processing appliances, manufacturing tools, etc., can solve the problems of reduced performance, low density of finished products, easy splitting, etc., to reduce the generation of scraps, improve product yield, Smooth and soft texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

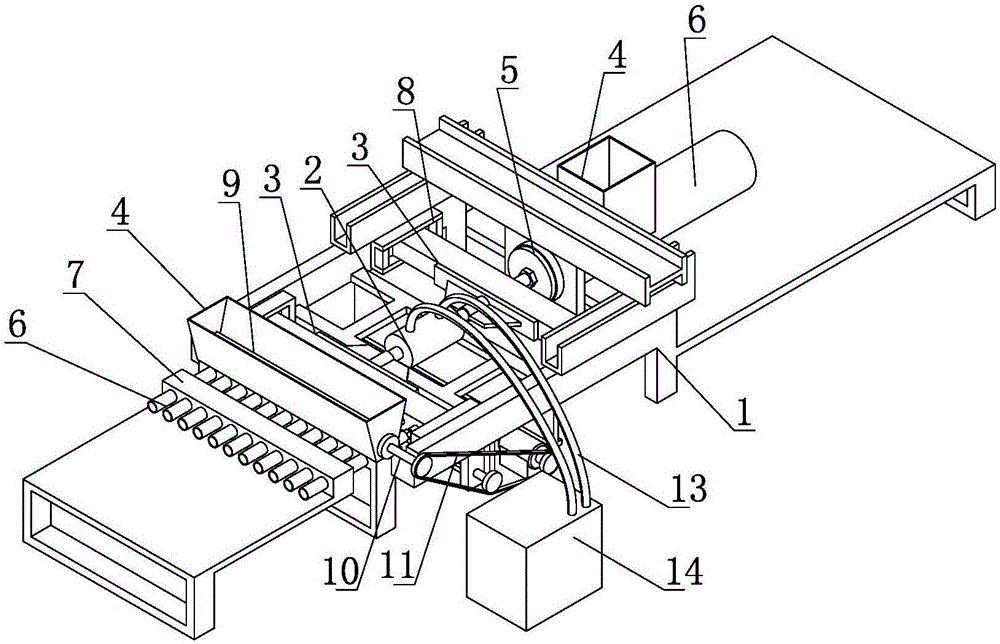

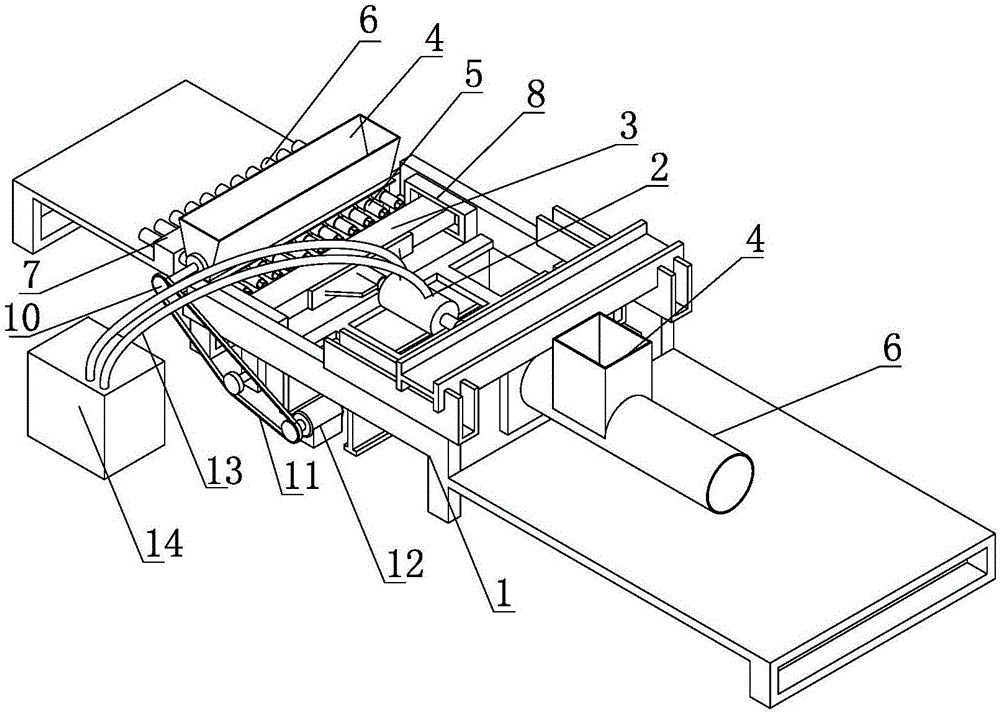

[0048] The production process of a kind of cork pad of the present invention comprises the following steps: material selection → glue mixing → hot pressing bar → curing → cutting → polishing (sanding) → dust removal → (printing) → finished product → (packaging), wherein

[0049] (1) Material selection: Cork bark is crushed, sorted, and impurity removed to obtain cork particles of different sizes. In this implementation, four sizes of large cork particles of 4 mesh, 8 mesh, 10 mesh, and 12 mesh are used. Mix in a ratio of 1:1:1:1.

[0050] In order to ensure the quality of the cork pad, the selected cork bark in the present invention requires as little black bark as possible, which can ensure that the finished product has both soft toughness and impact resistance; the moisture content of the cork particles is about 10%-12%, and the cork The lighter the bulk density of the particles, the better. Choose cork particles with a bulk density of 60-100 kg / m³, preferably 60-80 kg / m³; ...

Embodiment 2

[0080] Based on the process steps of Example 1, the difference of this embodiment is that the cork particles selected are of different sizes. In this implementation, the small cork particles of two specifications of 16 mesh and 32 mesh are respectively used, and mixed according to the ratio of 2:2, also Cork mats with different patterns can be made by adapting to the above process.

[0081] The production process of the cork mat of the present invention is through specific raw material selection and proportioning, and adopts a special hot pressing bar machine to realize the continuous production of feeding-while heating-while pressing the mold-while discharging, so that the formed rod The feed amount per unit area in the pipe 6 is small, the pipe pressure is high, the temperature is high, and the material for one-time heating is small, so that the adhesive and cork particles can be heated and combined evenly, so that the density and strength of the product can be greatly improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com