A system and method for comprehensive utilization of lng

A technology of heat exchanger and air conditioner, applied in the field of LNG comprehensive utilization system, which can solve the problems of LNG loss, complicated device/system structure, numerous devices or equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

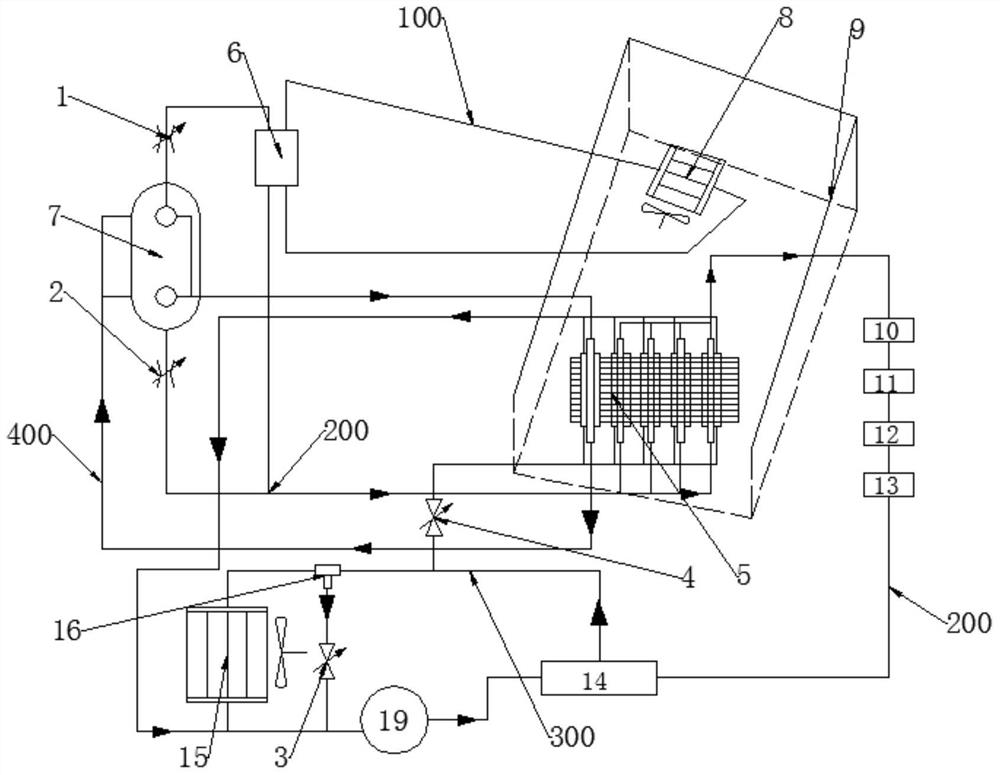

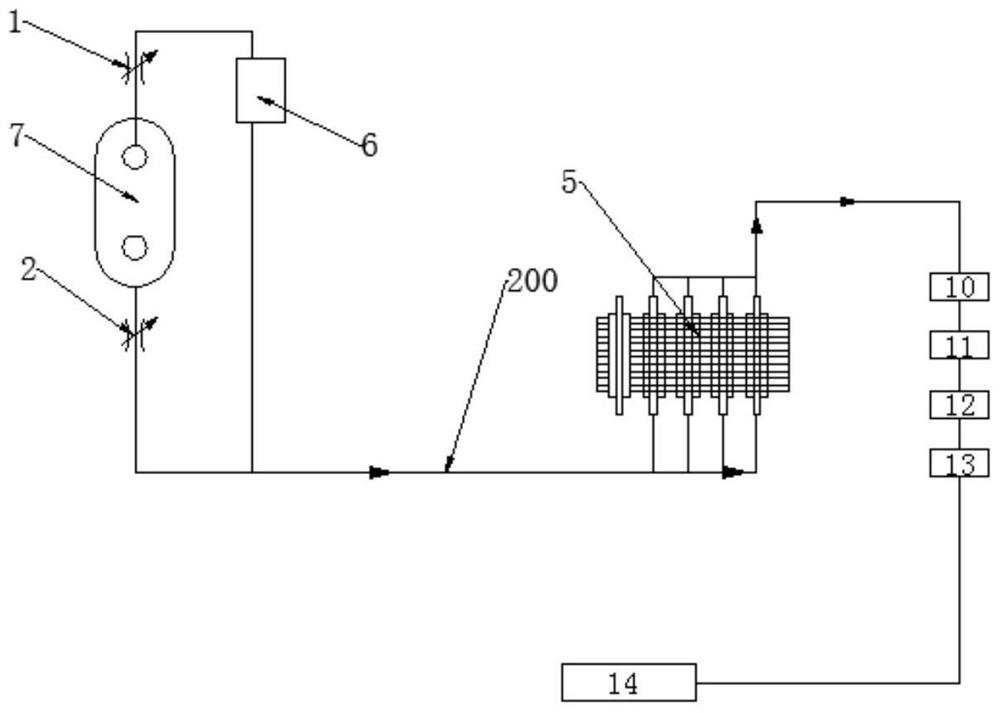

[0041] Embodiment 1: see attached Figure 1-3 , an LNG comprehensive utilization system, which includes an LNG storage tank 7, a first heat exchanger 6, a second heat exchanger 5, an air-conditioning pipeline 100, an air supply pipeline 200 and a coolant pipeline 300, wherein:

[0042] The second heat exchanger 5 is arranged in the air duct 9 of the air conditioning box;

[0043] One end of the air-conditioning pipeline 100 is connected to the evaporator 8, and the other end is connected to the first heat exchanger 6. The evaporator 8 is arranged in the air duct 9 of the air-conditioning box. After the heat exchange operation in the first heat exchanger 6, the air-conditioning pipeline 100 returns to the evaporator 8, and the air in the air-conditioning box air duct 9 is cooled by the air-conditioning refrigerant, and then enters the air-conditioning use room;

[0044] The gas supply pipeline 200 includes a main pipeline and two branch pipelines, the two branch pipelines are ...

Embodiment 2

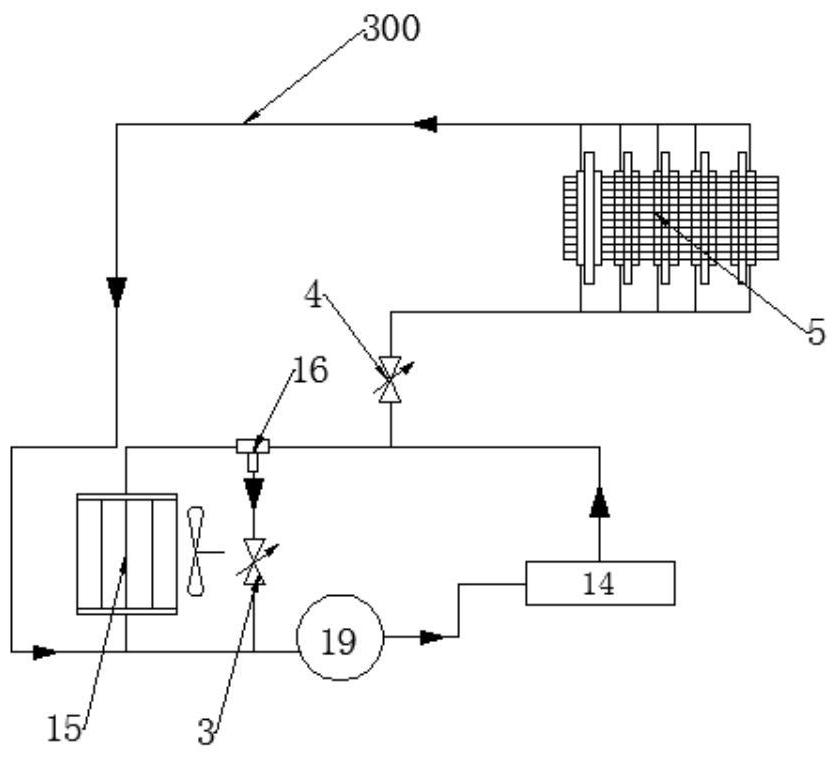

[0048] Embodiment 2: see attached figure 1 with 4 , the described LNG comprehensive utilization system also includes a self-pressurization pipeline 400, one end of the self-pressurization pipeline 400 is connected with the liquid outlet of the LNG storage tank 7, and the other end passes through the second heat exchanger 5 and connects with the LNG Storage tank 7 air inlets are connected.

[0049] By adopting the above-mentioned technical scheme, the liquid LNG is gasified and flowed back into the LNG storage tank 7 after exchanging heat in the second heat exchanger 5, and the pressure in the LNG storage tank 7 increases to provide sufficient power for the LNG gas outlet without using a booster. Pressure pump or conveying pump, saving equipment cost and reducing energy loss.

Embodiment 3

[0050] Embodiment 3: described a kind of LNG comprehensive utilization system also comprises PLC controller and temperature sensor, in air-conditioning use room, in the air duct 9 of air-conditioning box, engine 14 coolant inlet and natural gas inlet are respectively provided with temperature sensor, the first The control valve 1, the second control valve 2, the third control valve 3, the fourth control valve 4, the air supply main control valve 13 and the temperature sensor are respectively connected to the PLC controller; the temperature sensor is equivalent to the information collection unit of the PLC controller , pre-set the basic data in the PLC controller, when the information collected by each temperature sensor is sent back to the PLC controller for comparison, if everything is normal, the original state will be maintained, and if there is an abnormality, the PLC controller will report to each The control valve sends execution instructions until the data is normal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com