Full-automatic three-time packaging system for powdery materials

A fully automatic technology for powdery materials, applied in the field of automatic systems, can solve problems such as low efficiency, difficulty in forming product quality consistency, and inability to guarantee product hygiene quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

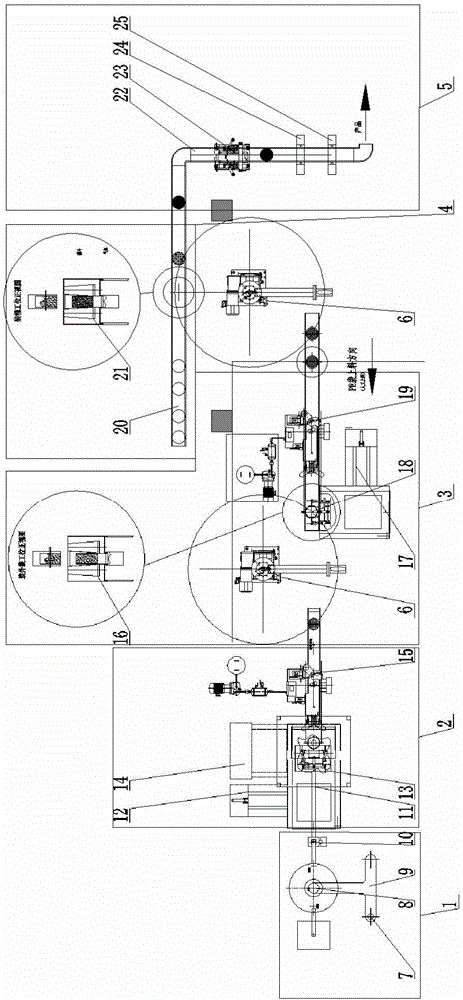

[0013] Such as figure 1 As shown, the fully automatic system for three sets of powder materials according to the present invention includes: screening system 1, inner bag packaging system 2, outer bag packaging system 3, barrel loading system 4, spraying code scanning assembly line 5, station conversion Cartesian coordinate robot 6. Control system.

[0014] Among them, the mechanical structure mainly includes: double cone dryer 7, vibrating screen 8, vacuum removal device 9, metal removal device 10, air delivery equipment 11, inner bag bagging machine 12, inner bag opening machine 13, weighing and feeding Machine 14, inner bag vacuum heat sealing machine 15, outer packaging guiding equipment 16, outer bag loading machine 17, outer bag opening machine 18, outer bag vacuum heat sealing machine 19, barrel guiding equipment 20, barrel guiding equipment 21 .

[0015] The screening system 1 and the inner bag packaging system 2 are connected through the process of the conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com