Method for preparing rare-earth phosphorate

A rare-earth phosphate and rare-earth carbonate technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of high reaction conditions and equipment requirements, difficulty in large-scale application, etc., and achieve easy filtration and washing, simple process, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Get the high-purity lanthanum carbonate produced by Zibo Baotou Steel Ganoderma Lucidum Rare Earth Reprocessing Workshop, and follow the steps below:

[0032] (1) Add 2000mL of pure water into a 5000mL beaker, start stirring, and add 500 grams of high-purity lanthanum carbonate to obtain a suspension of lanthanum carbonate.

[0033] (2) Slowly add 28% phosphoric acid into the suspension of lanthanum carbonate at room temperature under continuous stirring until the pH value is 1.5.

[0034] (3) Stir continuously for 30 minutes, the detected pH value is still 1.5, and the reaction reaches the end point.

[0035] (4) Suction filter the precipitate, wash 5 times with pure water, and obtain the lanthanum phosphate product.

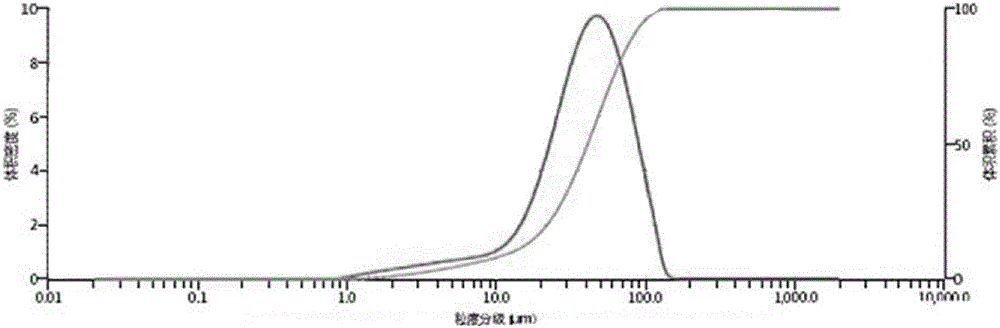

[0036] The prepared lanthanum phosphate product was dried in a 90-degree oven, and the particle size was detected. The test results are shown in Table 1, and the particle size distribution curve is shown in figure 1 .

Embodiment 2

[0038] Get the lanthanum, cerium and terbium carbonate produced by Zibo Baotou Steel Ganoderma lucidum rare earth research and development center, and follow the steps below:

[0039] (1) Add 1000mL of pure water into a 5000mL beaker, start stirring, and add 100 grams of lanthanum cerium carbonate to obtain a suspension of lanthanum cerium terbium carbonate.

[0040] (2) Slowly add 42% phosphoric acid to the suspension of lanthanum, cerium and terbium carbonate at room temperature under continuous stirring until the pH value is 1.0.

[0041] (3) Continue to stir for 10 minutes, and detect that the pH value is 1.5, and the reaction reaches the end point.

[0042] (4) Suction filter the precipitate, wash with pure water 6 times to obtain the lanthanum cerium terbium phosphate product.

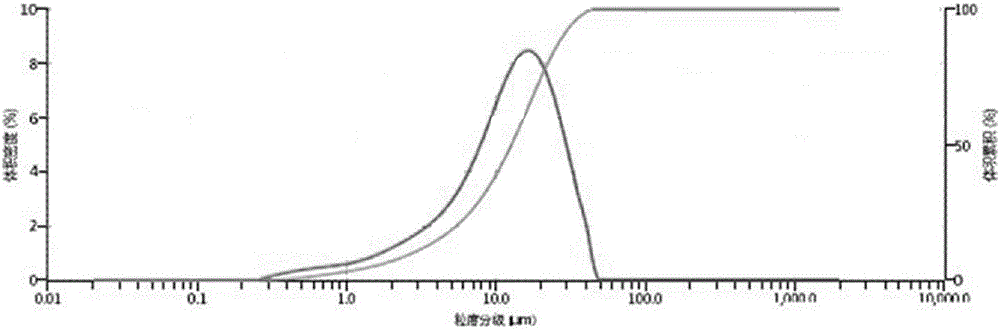

[0043] Dry the prepared lanthanum cerium terbium phosphate in a 90-degree oven to detect the particle size. The test results are shown in Table 1, and the particle size distribution curve is sho...

Embodiment 3

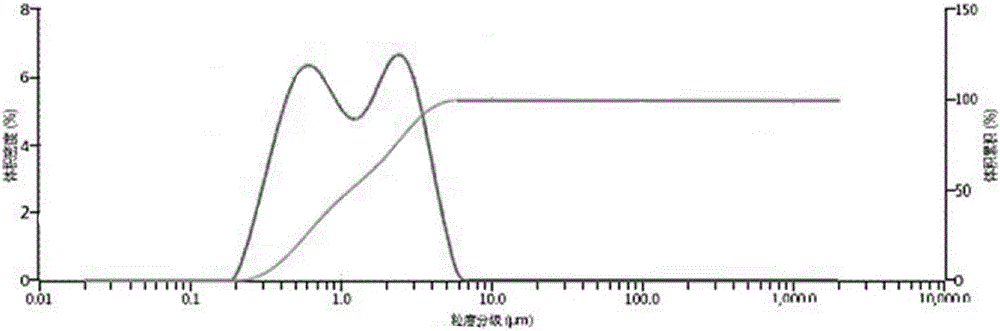

[0045] Get the neodymium carbonate produced by Zibo Baotou Steel Ganoderma lucidum rare earth post-processing workshop, and follow the steps below:

[0046] (1) Add 2000L of pure water to a 5000L reactor, start stirring, add 500 kg of neodymium carbonate to obtain a suspension of neodymium carbonate.

[0047] (2) Slowly add 20% ammonium dihydrogen phosphate to the neodymium carbonate suspension under constant stirring at room temperature until the pH value is 4.5.

[0048] (3) Stirring was continued for 10 minutes, the detected pH value rose to 5.5, and 40% phosphoric acid was added to make the pH value 4.5. Stirring was continued for 30 minutes, the detected pH value was still 4.5, and the reaction reached the end point.

[0049] (4) Centrifuge and dehydrate the precipitate, rinse it with pure water for 15 minutes, and obtain the neodymium phosphate product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com