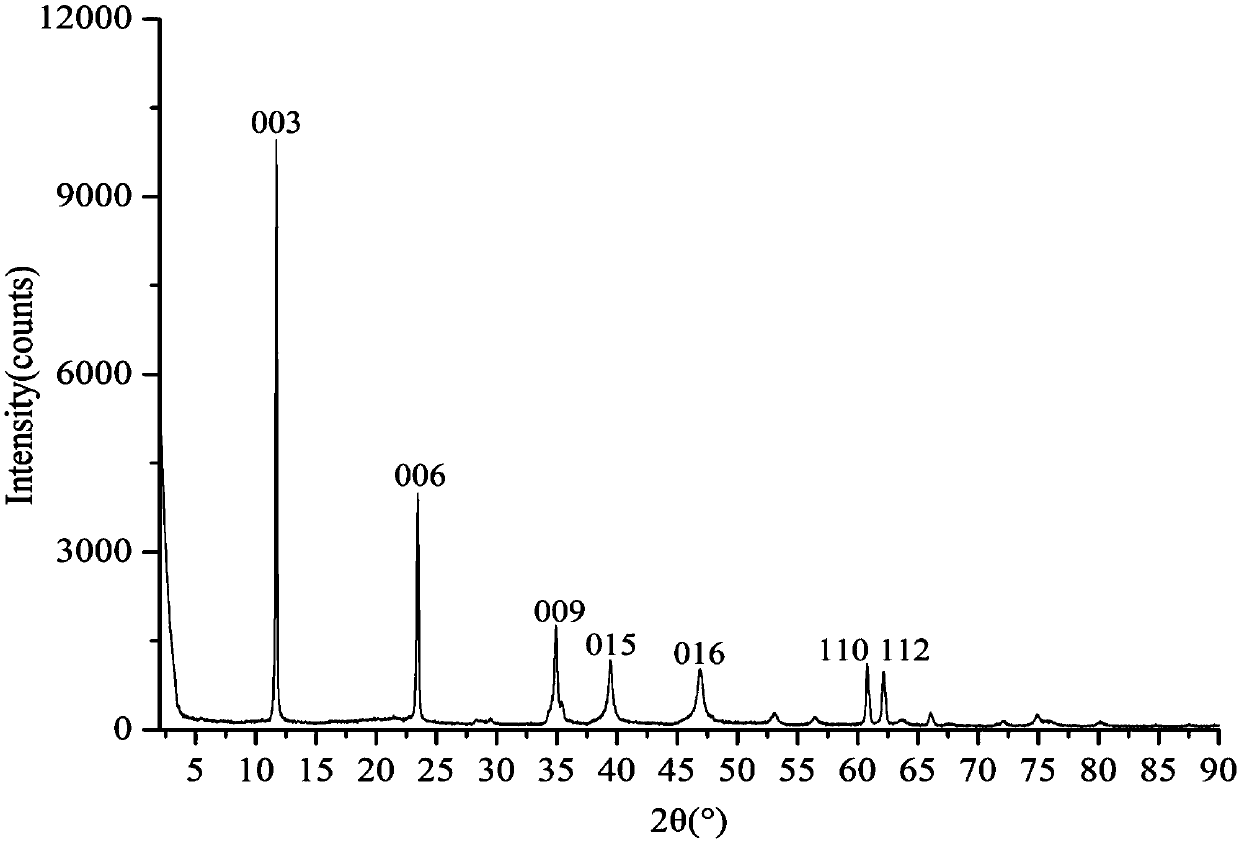

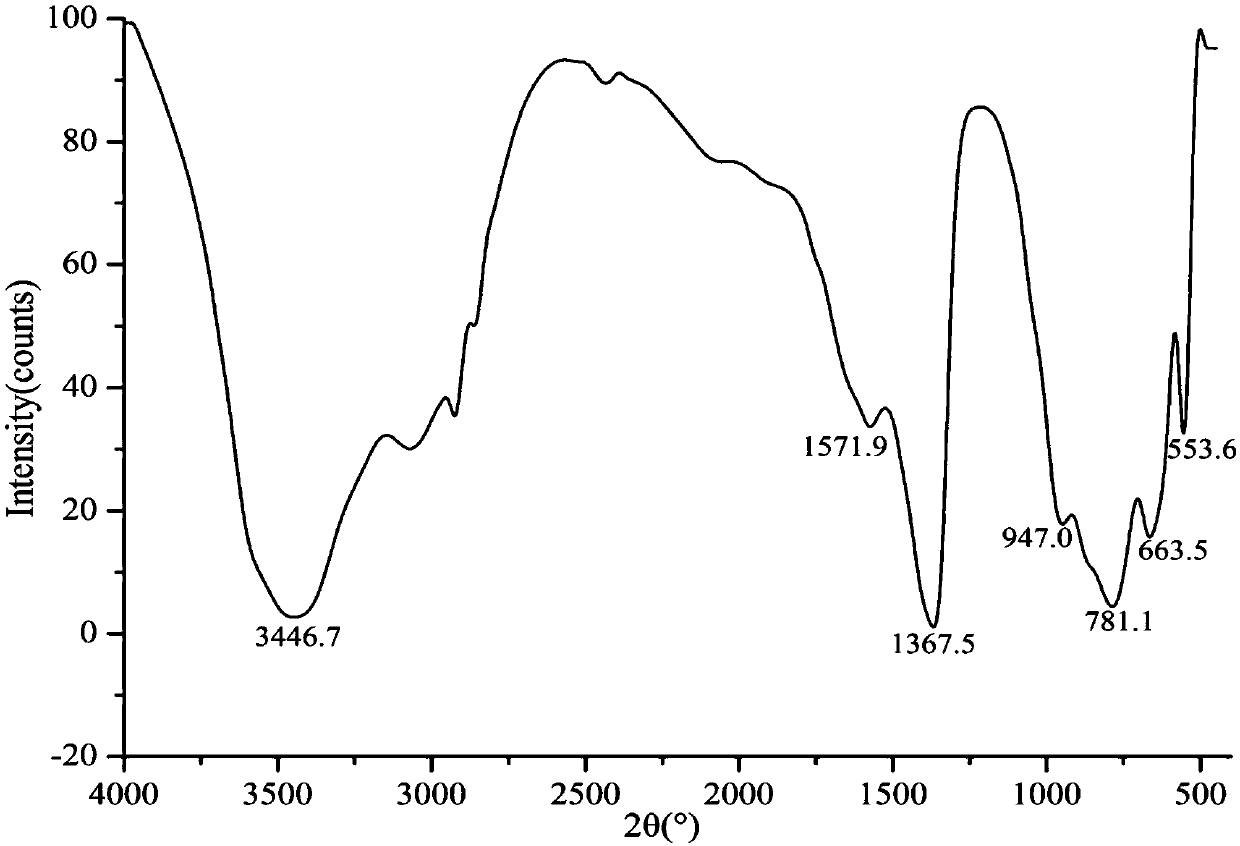

Synthesis of magnesium-aluminum toluene-4-sulfonate sodium pillared hydrotalcite

A technology of sodium sulfonate and hydrotalcite, applied in aluminum compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of low efficiency, complicated operation, time-consuming and energy-consuming, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

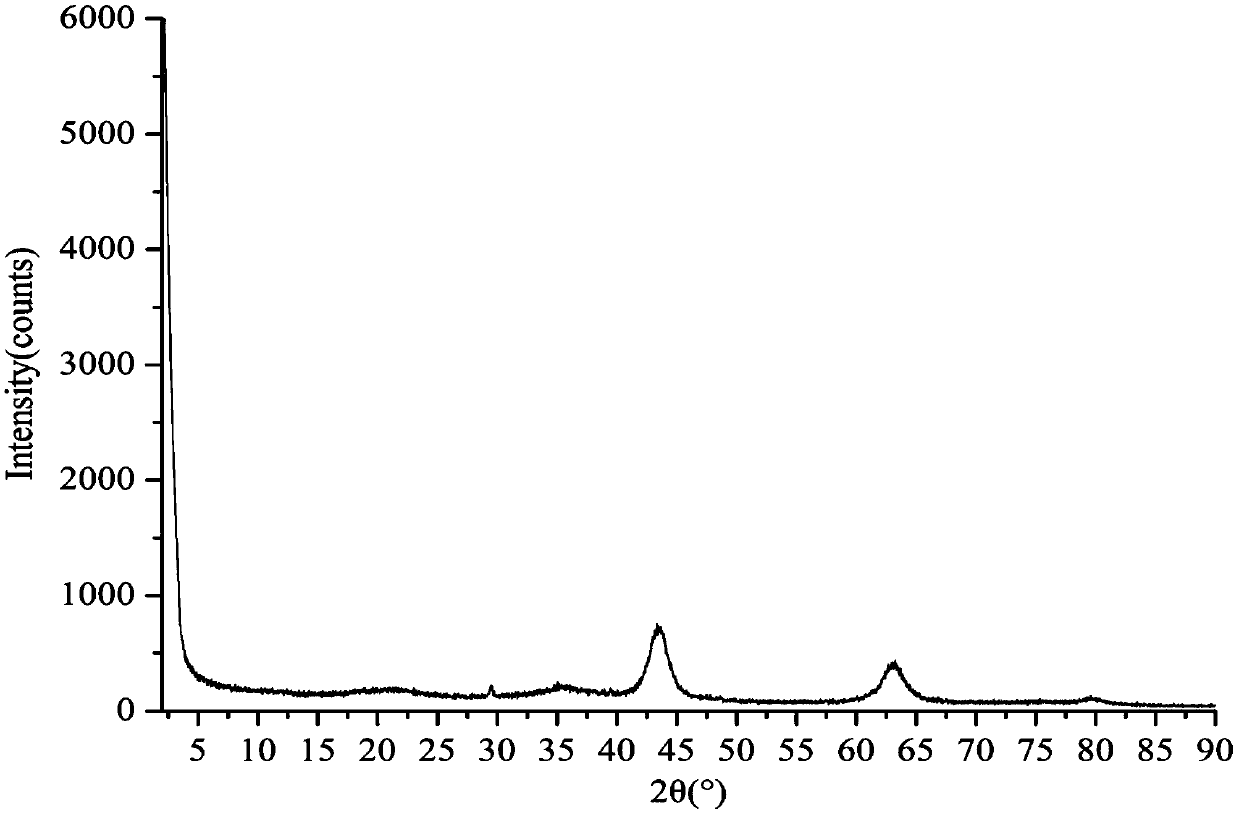

[0055] (1) Roasting: the precursor magnesium aluminum type hydrotalcite Mg 6 Al 2 (OH) 16 CO 3 4H 2 O is placed in a muffle furnace at a heating rate of 5°C

[0056] / min heated to a temperature of 500°C and roasted for 6 hours to obtain the roasted product Mg 6 Al 2 o 8 (OH) 2 ;

[0057] (2) Weighing: Weigh 11.711g of the intercalation agent toluene-4-sodium sulfonate and 7.236g of the roasted product Mg in a microwave digestion tank 6 Al 2 o 8 (OH) 2 , the amount ratio of the two substances is 3:1.

[0058] (3) Microwave crystallization hydrothermal synthesis: Boil deionized water and keep it for 30 minutes, then add 100mL to the above-mentioned microwave digestion tank with intercalation agent and roasted product, seal it, and place the microwave digestion tank in a microwave digestion instrument , microwave heating at 100°C for 30 minutes to complete the synthesis;

[0059] (4) Washing and drying: Pour out all the solids and liquids in the microwave digestion...

Embodiment 2

[0061] (1) Roasting: the precursor magnesium aluminum type hydrotalcite Mg 6 Al 2 (OH) 16 CO 3 4H 2 O is placed in a muffle furnace, heated to a temperature of 500°C at a heating rate of 5°C / min, and roasted for 5 hours to obtain the roasted product Mg 6 Al 2 o 8 (OH) 2 ;

[0062] (2) Weighing: Weigh 15.615g of the intercalation agent toluene-4-sodium sulfonate and 7.236g of the roasted product Mg in a microwave digestion tank 6 Al 2 o 8 (OH) 2 , the amount ratio of the two substances is 4:1.

[0063] (3) Microwave crystallization hydrothermal synthesis: Boil deionized water and keep it for 60 minutes, then add 100mL to the above-mentioned microwave digestion tank with intercalation agent and roasted product, seal it, and place the microwave digestion tank in a microwave digestion instrument , microwave heating at 180°C for 60 minutes to complete the synthesis;

[0064] (4) Washing and drying: Pour out all the solids and liquids in the microwave digestion tank, bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com