Integrated wastewater treatment equipment of IBR (integral biological reactor) and treatment process

A wastewater treatment and reactor technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. , to achieve the effect of improving precipitation efficiency, reducing cost and power consumption, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

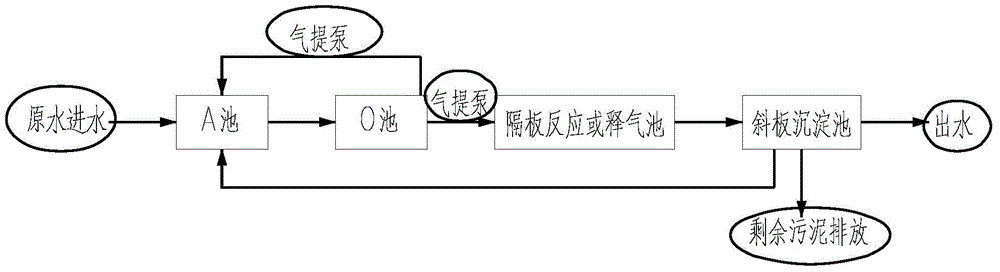

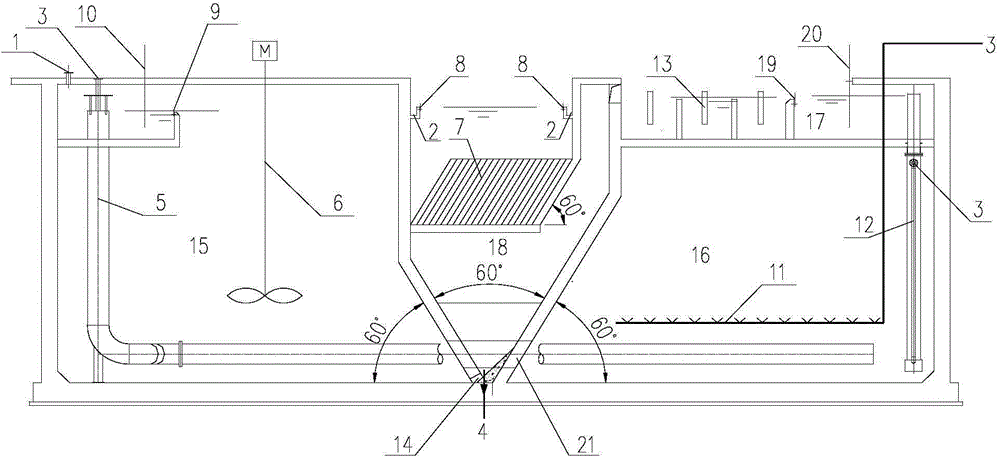

[0030] see figure 1 , figure 2 , This embodiment consists of four parts: A / O biochemical pool, reaction and degassing pool 17, and sedimentation pool 18. This embodiment has an integrated structure, and the total height is between 6 and 8 m. This embodiment is a reinforced concrete structure or a steel structure. The steel structure is made of carbon steel anti-corrosion, SS304, SS316 and other stainless steel materials.

[0031] The A / O biochemical pool is divided into A pool 15 and O pool 16. The sedimentation tank 18 is placed between the A pool 15 and the O pool 16, which naturally separates the A / O system. The A pool 15 is open or semi-open Or fully enclosed, the present embodiment is an open type. A pond 15 is provided with waste water inlet 1, mixed solution backflow port, and the bottom of A pond 15 is provided with the pipeline that communicates with O pond 16, and A pond 15 is provided with mixed liquor reflux lift pump 5, air pipe 3, mixer 6, The mixing of mud ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com