Adhesive material for restoration of ancient architecture of masonry structure and preparation method

A technology of masonry structure and bonding material, applied in the field of building materials, can solve the problems of slow curing speed, poor dry shrinkage resistance, insufficient building compressive strength, etc., and achieve the effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

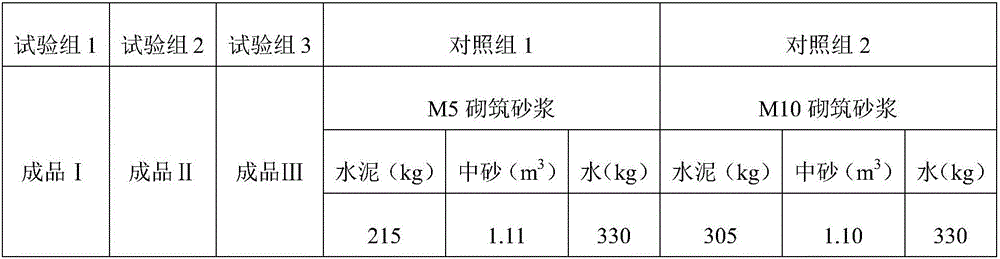

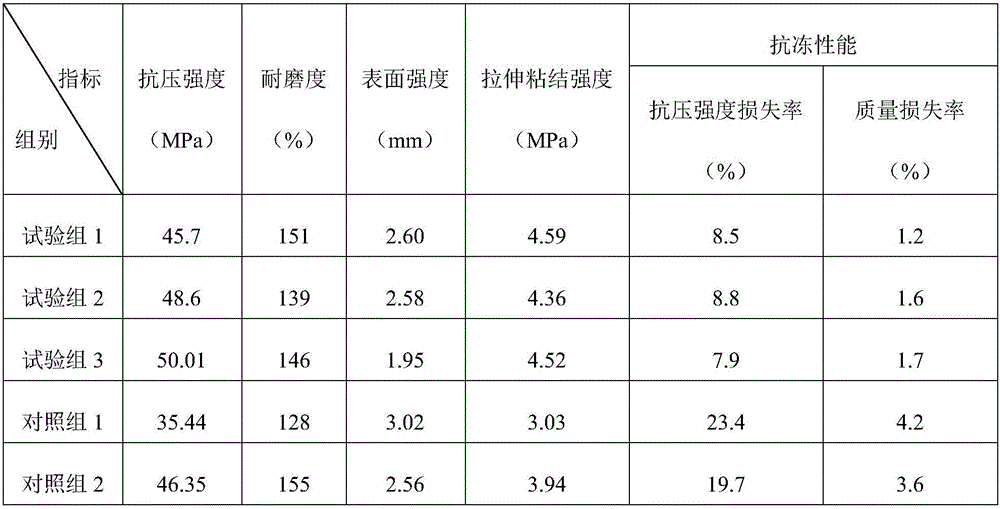

Examples

Embodiment 1

[0034] Embodiment 1, finished product I, a kind of bonding material for repairing ancient buildings with masonry structure, is made up of the following materials in parts by mass: 45 parts of gel material, 15 parts of fine aggregate, 5 parts of reinforcing material, 0.6 part of water-reducing agent, 0.5 parts of antifreeze and 16 parts of water; calculated in parts by mass, the gel material is composed of 15 parts of glutinous rice porridge, 5 parts of lime, 5 parts of gypsum and 8 parts of clay; calculated in parts by mass, the fine The aggregate is composed of 5 parts of natural sand, 10 parts of coal ash and 25 parts of slag; calculated in parts by mass, the reinforcing material is composed of 35 parts of hemp knife, 7 parts of pulp, 2 parts of rice bran and 3 parts of bamboo fiber.

[0035] The water reducer is sodium lignosulfonate water reducer, the natural sand is sea sand, the fineness modulus of the sea sand is 2.2, the particle size of the slag is 0.6 mm, and the anti...

Embodiment 2

[0049] Embodiment 2, finished product II, a kind of bonding material for repairing ancient buildings with masonry structure, consists of the following materials in parts by mass: 65 parts of gel material, 25 parts of fine aggregate, 10 parts of reinforcing material, 1.5 parts of water reducing material agent, 1.2 parts of antifreeze and 28 parts of water; calculated in parts by mass, the gel material is composed of 38 parts of glutinous rice porridge, 12 parts of lime, 12 parts of gypsum and 13 parts of clay; calculated in parts by mass, the fine The aggregate is composed of 12 parts of natural sand, 25 parts of coal ash and 40 parts of slag; calculated in parts by mass, the reinforcing material is composed of 46 parts of hemp knife, 13 parts of pulp, 6 parts of rice bran and 7 parts of bamboo fiber.

[0050] The water reducer is a polycarboxylate water reducer, the natural sand is sea sand, the fineness modulus of the sea sand is 2.5, the particle diameter of the slag is 0.8 m...

Embodiment 3

[0064] Embodiment 3, finished product III, a kind of bonding material for repairing ancient buildings with masonry structure, consists of the following materials in parts by mass: 55 parts of gel material, 20 parts of fine aggregate, 7 parts of reinforcing material, 1 part of water reducing material agent, 1 part of antifreeze and 22 parts of water; calculated in parts by mass, the gel material is composed of 27 parts of glutinous rice porridge, 8 parts of lime, 7 parts of gypsum and 10 parts of clay; calculated in parts by mass, the fine The aggregate is composed of 7 parts of natural sand, 18 parts of coal ash and 33 parts of slag; calculated by mass parts, the reinforcing material is composed of 40 parts of hemp knife, 10 parts of pulp, 4 parts of rice bran and 5 parts of bamboo fiber.

[0065] The water reducer is a mixture of sodium lignosulfonate water reducer and polycarboxylate water reducer in a ratio of 1:1, the natural sand is sea sand, and the fineness modulus of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com