Compound microbial fertilizer produced from tobacco waste

A technology of compound microorganisms and tobacco waste, applied in the field of compound microorganism fertilizer, can solve problems such as pollution and scourge, and achieve the effects of maximizing fertilizer efficiency and fertility, improving soil structure, and reducing construction, operation and maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

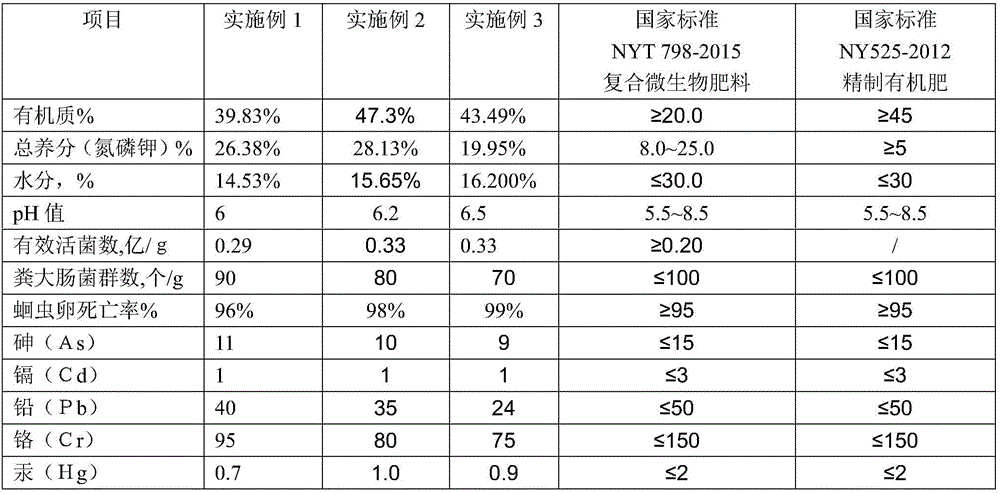

Embodiment 1

[0040] 1. Pulverizing and mixing: crushing tobacco waste and defective soybeans to obtain 60-80 mesh tobacco powder, adding 7% defective soybean powder, 15% mushroom dregs, and 8% bran chaff by total weight, and entering The mixed material is made from smoke powder, the actual amount of smoke powder is 70%, and the material indicators after fermentation and maturity are: organic matter 65%, nitrogen 2.72%, phosphorus 0.73%, potassium 5.46%, moisture 21.55%.

[0041] 2. Inoculation fermentation: add the composite fermentation strains into the mixed material and stir evenly, the weight ratio added is the composite fermentation strains: the inoculation amount is 0.1%, then add tobacco extract to adjust the humidity of the material to 40%, fully stir Evenly, pile up into stacks (do not cover with plastic film, etc.) for fermentation.

[0042] 3. Turning and decomposing: When the temperature rises above 60°C, keep warm for 1-2 days, and then turn; when the temperature of the materi...

Embodiment 2

[0047] 1. Pulverizing and mixing: crushing tobacco waste and defective soybeans to obtain 60-80 mesh smoke powder, adding 5% defective soybean powder, 15% mushroom dregs, 5% bran chaff by total weight, and entering The mixed material is made from tobacco powder, the actual amount of tobacco powder is 75%, and the material indicators after fermentation and maturity are: organic matter 66.5%, nitrogen 2.61%, phosphorus 0.68%, potassium 5.72%, moisture 22.5%.

[0048] 2, inoculation fermentation: add compound fermentation strain in the mixed material and stir evenly, the weight ratio of adding is compound fermentation strain: inoculum amount is 0.1%, then add tobacco leachate and adjust the humidity of material to 40-50%, Stir well, pile up into stacks (do not cover with plastic film, etc.) for fermentation.

[0049] 3. Turning and decomposing: When the temperature rises above 60°C, keep warm for 1-2 days, and then turn; when the temperature of the material rises to above 60°C ag...

Embodiment 3

[0054] 1. Pulverizing and mixing: crushing tobacco waste and defective soybeans to obtain 60-80 mesh smoke powder, adding 10% defective soybean powder, 15% mushroom dregs, 8% bran chaff by total weight, and entering The mixed material is made from tobacco powder, the actual amount of tobacco powder is 67%, and the material indicators after fermentation and maturity are: organic matter 66.9%, nitrogen 2.79%, phosphorus 0.78%, potassium 5.35%, moisture 21.39%.

[0055] 2, inoculation fermentation: add compound fermentation strain in the mixed material and stir evenly, the weight ratio of adding is compound fermentation strain: inoculum amount is 0.1%, then add tobacco leachate and adjust the humidity of material to 40-50%, Stir well, pile up into stacks (do not cover with plastic film, etc.) for fermentation.

[0056] 3. Turning and decomposing: When the temperature rises above 60°C, keep warm for 1-2 days, and then turn; when the temperature of the material rises to above 60°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com