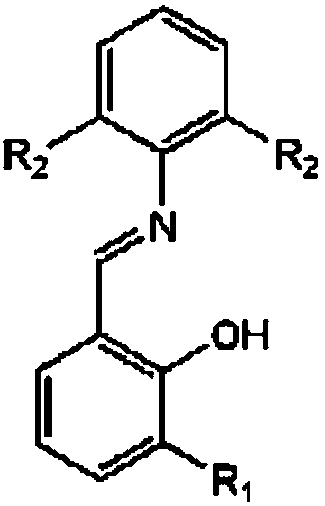

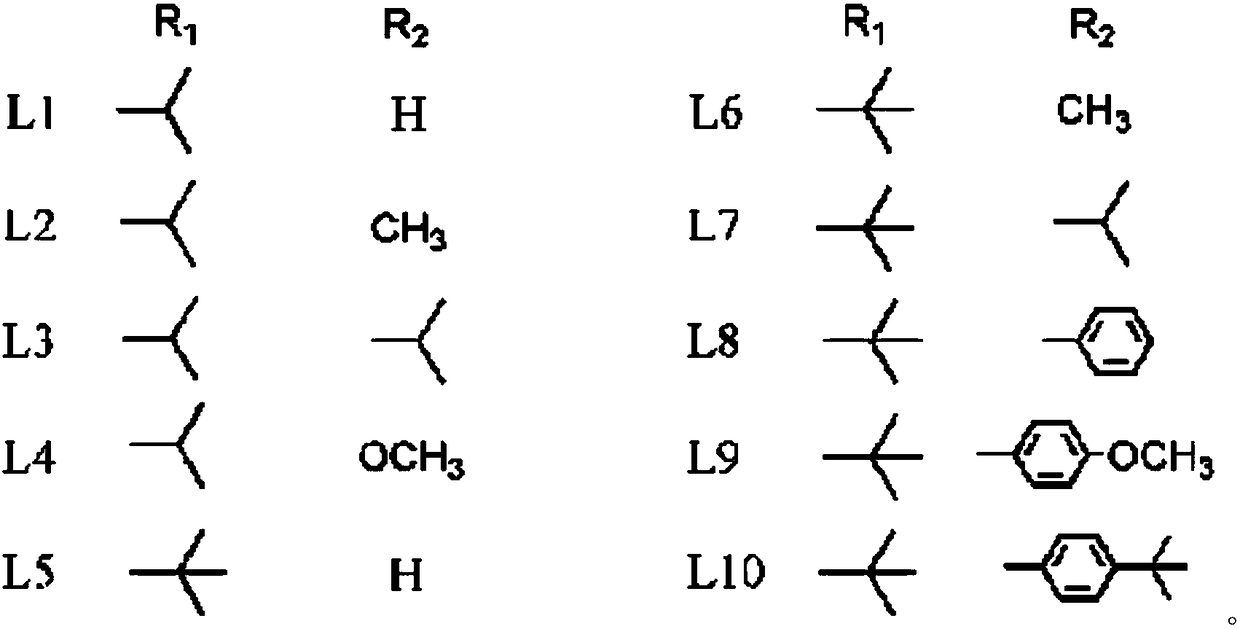

A kind of supported mgcl2/tcl4 catalyst modified by salicylaldimine type modifier and its preparation method and application

A technology of salicylaldimine type and catalyst, which is applied in the chemical industry to achieve the effect of increasing insertion amount, uniform composition distribution and increasing molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take about 1g of industrial loaded TiCl 4 / MgCl 2 Catalyst, add 20mL of n-heptane. According to the molar ratio of modifier to Ti being 0.5, take a corresponding amount of modifier L1, dissolve it in 30 mL of n-heptane, add it all at once to the reaction system, and continue to stir and react at 30°C for 4 hours. Stand for stratification, take out the supernatant, wash twice with 20mL n-heptane, take out the supernatant, and finally vacuum-dry at 60°C to obtain the modified catalyst Cat-1.

[0030]Using 17mg of Cat-1 as the main catalyst, catalyzed the slurry polymerization of ethylene and 1-hexene in a 100mL round bottom flask at 60°C and normal pressure under the protection of nitrogen. TEA was added as a cocatalyst according to the aluminum-titanium molar ratio of 100, 1-hexene was added as a co-monomer at a concentration of 0.2 mol / L, and 50 mL of n-heptane was used as a solvent, and polymerized for 30 minutes to obtain 4.1 g of a polymer. The catalytic activity ...

Embodiment 2

[0032] The preparation method of modified catalyst and polymerization condition are all the same as embodiment 1, only promotor TEA is changed into MAO. 4.7 g of polymer were obtained. The catalytic activity was 554 g polymer / g catalyst·h. The weight average molecular weight of the polymer is 143.9 kg / mol, the molecular weight distribution index is 6.7, the 1-hexene structural unit content in the polymer is 7.6 mol%, [H]s / [H]i=5.2.

Embodiment 3

[0034] The preparation method and polymerization conditions of the modified catalyst are all the same as in Example 1, except that the cocatalyst TEA is changed into MMAO. 4.9 g of polymer were obtained. The catalytic activity was 578 g polymer / g catalyst·h. The weight average molecular weight of the polymer is 152.3 kg / mol, the molecular weight distribution index is 5.8, the 1-hexene structural unit content in the polymer is 7.8 mol%, [H]s / [H]i=3.8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com