Acrylamide copolymer, preparation method and application thereof

An acrylamide copolymer and acrylamide copolymerization technology, applied in the application field of acrylamide copolymer, can solve the problems of small molecular weight of the product, limitations of polymer application, cumbersome process operation, etc., and achieve high molecular weight, low residual monomer content, Good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

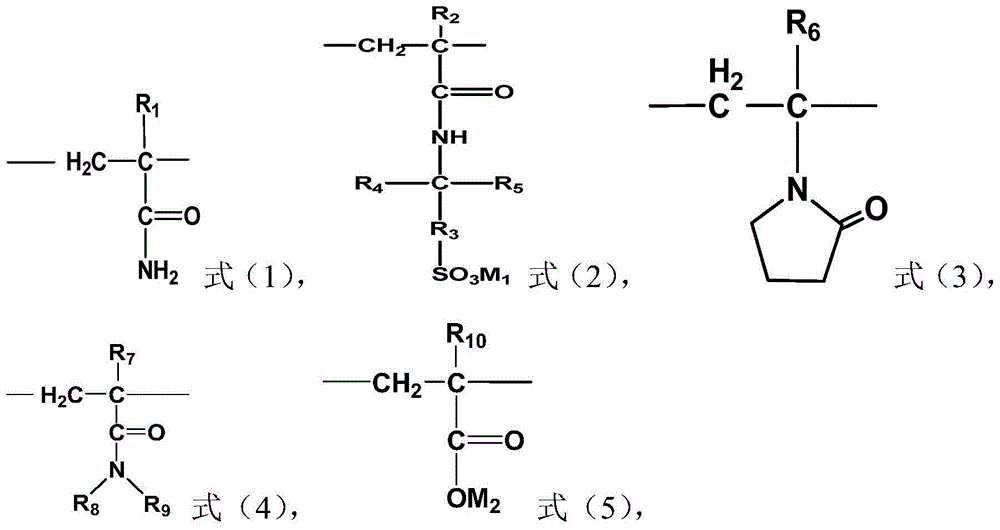

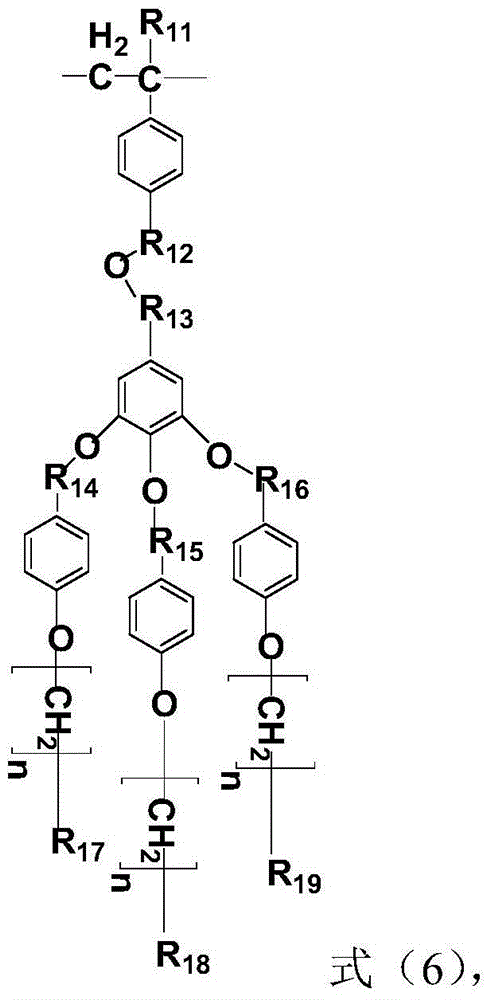

[0038] The present invention also provides a method for preparing an acrylamide copolymer, the preparation method comprising: polymerizing a monomer mixture in water under solution polymerization conditions and in the presence of an initiator, wherein the monomer The mixture contains monomer E, monomer F and monomer G, the monomer E is a monomer having a structure shown in formula (8), and the monomer F is a monomer having a structure shown in formula (9)-(12) At least one of the monomers of the structure, the monomer G is a monomer having a structure shown in formula (13), and the weight ratio of the monomer E, the monomer F and the monomer G is 1: 0.001-10: 0.001-10, more preferably 1: 0.01-1.5: 0.01-0.2, most preferably 1: 0.01-1: 0.01-0.1; the solution polymerization reaction conditions make the polymer obtained after the polymerization reaction The viscosity average molecular weight is 30 million-38 million, preferably 32 million-35 million,

[0039]

[0040]

[00...

Embodiment 1

[0082] This embodiment is used to illustrate the preparation method of the acrylamide copolymer provided by the present invention

[0083] Add 1000 grams of acrylamide (AM), 10 grams of 2-acrylamido-2-methylpropanesulfonic acid and 10 grams of surface-active functional monomers of the structure shown in formula (15), 4080 grams of deionized water in a beaker , under stirring, the temperature of the solution was controlled at 5°C with frozen brine, and the pH was adjusted to 7 by adding sodium hydroxide. Transfer the monomer solution to a polymerization bottle, add 10.2 mg of water-soluble azo initiator 2,2'-azobis(2-amidinopropane) dihydrochloride and 10.2 mg of amine N,N,N', For N'-tetramethylethylenediamine, deoxygenate with high-purity nitrogen gas for 0.5 hour, add 10.2 mg of sodium bisulfite and 10.2 mg of ammonium persulfate, continue nitrogen gas flow until the thermocouple in the polymerization bottle starts to heat up, and the reaction time is 8 hours. The colloid is...

Embodiment 2

[0085] This embodiment is used to illustrate the preparation method of the acrylamide copolymer provided by the present invention

[0086] Add 1000 grams of acrylamide (AM), 1000 grams of 2-acrylamido-2-methylpropanesulfonic acid and 100 grams of surface-active functional monomers of the structure shown in formula (15), 4900 grams of deionized water in a beaker , under stirring, the temperature of the solution was controlled at 15°C with frozen brine, and the pH was adjusted to 7 by adding sodium hydroxide. Transfer the monomer solution to a polymerization bottle, add 1.05 grams of water-soluble azo initiator 2,2'-azobis(2-amidinopropane) dihydrochloride and 1.05 grams of amines N,N,N', For N'-tetramethylethylenediamine, deoxygenate with high-purity nitrogen for 0.5 hour, add 1.05 grams of sodium bisulfite and 1.05 grams of ammonium persulfate, and continue to pass nitrogen until the thermocouple in the polymerization bottle starts to heat up, and the reaction time is 4 hours....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com