Long-acting, anti-bacterial and mould-proof ABS (acrylonitrile butadiene styrene) functional material and preparation method thereof

A functional material, antibacterial and antifungal technology, applied in the field of modified plastics, can solve the problems of short aging, low efficiency of antibacterial plastics, etc., and achieve the effect of low cost, long-term antibacterial and antifungal characteristics, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

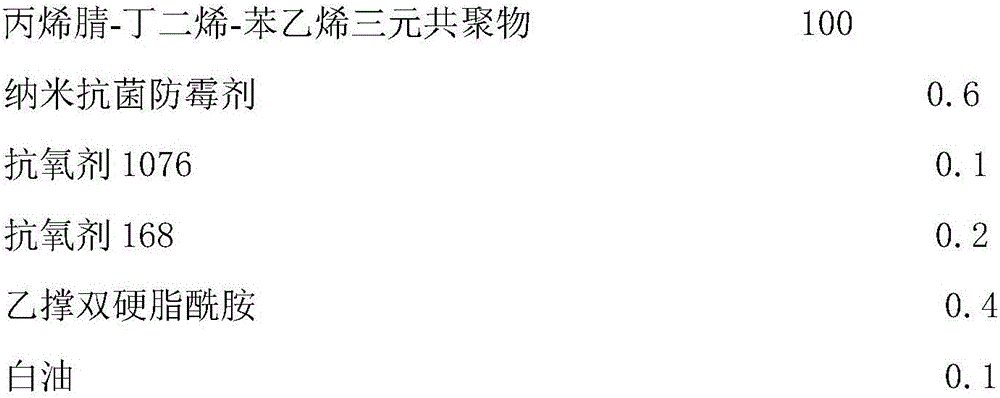

[0034] The long-acting antibacterial and antifungal ABS functional material in this embodiment is composed of the following raw materials in parts by weight:

[0035]

[0036] The specific preparation method includes the following steps:

[0037] (1) Add the acrylonitrile-butadiene-styrene terpolymer and white oil into the high-mixer and mix at a speed of 150r / min for 5 minutes;

[0038] (2) Add the nano antibacterial and antifungal agent, antioxidant and lubricant to the high-mixer and mix for 1 minute at a speed of 400r / min;

[0039] (3) Add the mixture in step (2) to the mixture in step (1), and mix in a high mixer at a speed of 200r / min for 10 minutes;

[0040] (4) Put the mixture in step (3) into a parallel twin-screw extruder to melt, melt, mix, extrude, and pellet to obtain a long-lasting antibacterial and antifungal ABS functional material, where the barrel temperature of the extruder is 180~210℃, screw speed is 400r / min, melt pressure is controlled at 1.5MPa, vacuum degree is ...

Embodiment 2

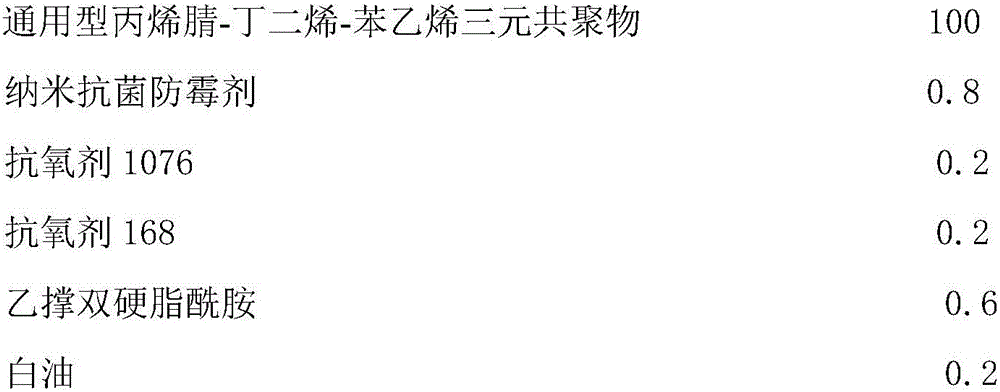

[0042] The long-lasting antibacterial and mildew resistant ABS functional material in this embodiment is composed of the following raw materials in parts by weight:

[0043]

[0044] The specific preparation method includes the following steps:

[0045] (1) Add the acrylonitrile-butadiene-styrene terpolymer and white oil into the high-mixer and mix at a speed of 200r / min for 4 minutes;

[0046] (2) Add the nano antibacterial and antifungal agent, antioxidant and lubricant to the high-mixer and mix for 2 minutes at a speed of 500r / min;

[0047] (3) Add the mixture in step (2) to the mixture in step (1), and mix in a high-mixer at 300r / min for 8 minutes;

[0048] (4) Put the mixture in step (3) into a parallel twin-screw extruder to melt, melt, mix, extrude, and pellet to obtain a long-lasting antibacterial and antifungal ABS functional material, where the barrel temperature of the extruder is 180~210℃, screw speed 450r / min, melt pressure controlled at 1.6MPa, vacuum degree -0.08MPa.

Embodiment 3

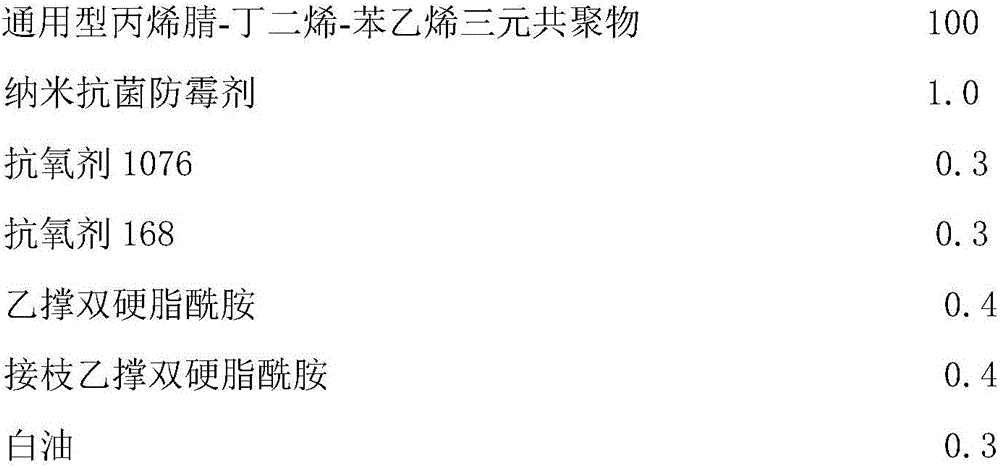

[0050] The long-lasting antibacterial and mildew resistant ABS functional material in this embodiment is composed of the following raw materials in parts by weight:

[0051]

[0052] The specific preparation method includes the following steps:

[0053] (1) Add the acrylonitrile-butadiene-styrene terpolymer and white oil to the high-mixer and mix at 250r / min for 3 minutes;

[0054] (2) Add the nano antibacterial and antifungal agent, antioxidant and lubricant to the high-mixer and mix for 1 minute at a speed of 600r / min;

[0055] (3) Add the mixture in step (2) to the mixture in step (1), and mix in a high mixer at a speed of 400r / min for 6 minutes;

[0056] (4) Put the mixture in step (3) into a parallel twin-screw extruder to melt, melt, mix, extrude, and pellet to obtain a long-lasting antibacterial and antifungal ABS functional material, where the barrel temperature of the extruder is 180~210℃, screw speed is 500r / min, melt pressure is controlled at 1.8MPa, vacuum degree is -0.1MPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com