A kind of multifunctional epoxy resin-based radiation protection composite material and preparation method thereof

A technology of epoxy resin and composite material, applied in the field of nuclear radiation protection, can solve problems such as restricting the scope of use, and achieve the effects of good neutron and gamma ray shielding performance, easy availability of raw materials, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

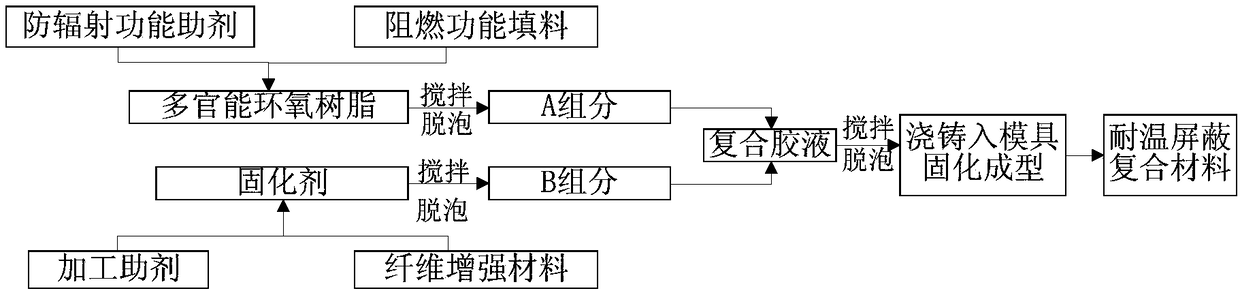

[0070] This embodiment provides a method for preparing a multifunctional epoxy resin-based radiation protection composite material. The process flow chart is as follows figure 1 Shown from figure 1 It can be seen that the preparation method includes the following specific steps:

[0071] When the matrix material is multifunctional epoxy resin, the prepared radiation protection composite material is divided into components A and B for storage separately, and mixed during use.

[0072] (1) The radiation protection composite material is prepared from the following components (as shown in Table 1) in parts by weight:

[0073] Table 1

[0074] raw material name

Mass parts

manufacturer

Glycidylamine type tetrafunctional epoxy resin

100 servings

Changshu Jiafa Chemical Company

Methyl Nadic Anhydride

140 servings

Polin Chemical

60 servings

Ning'an Bohai Boron Carbide Co., Ltd.

160 servings

Beijing Youxinglian Nonferrous Metals Co., Ltd.

car...

Embodiment 2

[0080] This embodiment provides a method for preparing a multifunctional epoxy resin-based radiation protection composite material. The process flow chart is as follows figure 1 Shown from figure 1 It can be seen that the preparation method includes the following specific steps:

[0081] When the matrix material is a multifunctional epoxy resin, the prepared radiation protection composite material is divided into components A and B for storage separately, and mixed during use.

[0082] (1) The radiation protection composite material is prepared by weight parts of the following components (as shown in Table 2):

[0083] Table 2

[0084] raw material name

Mass parts

manufacturer

Glycidylamine type tetrafunctional epoxy resin

100 servings

Changshu Jiafa Chemical Company

Diaminodiphenylsulfone

44 servings

Zhengzhou Shengkai Chemical Products Co., Ltd.

10 servings

Ning'an Bohai Boron Carbide Co., Ltd.

20 servings

Beijing Youxinglian Nonfer...

Embodiment 3

[0090] This embodiment provides a method for preparing a multifunctional epoxy resin-based radiation protection composite material. The process flow chart is as follows figure 1 Shown from figure 1 It can be seen that the preparation method includes the following specific steps:

[0091] When the matrix material is a multifunctional epoxy resin, the prepared radiation protection composite material is divided into components A and B for storage separately, and mixed during use.

[0092] (1) The radiation protection composite material is prepared by weight parts of the following components (as shown in Table 3):

[0093] table 3

[0094] raw material name

Mass parts

manufacturer

Glycidylamine type trifunctional epoxy resin

100 servings

Changshu Jiafa Chemical Company

Methyltetrahydrophthalic anhydride

138 copies

Polin Chemical

20 servings

Ning'an Bohai Boron Carbide Co., Ltd.

lead

200 servings

Beijing Youxinglian Nonferrous Metals Co., Ltd.

glass fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| coefficient of linear thermal expansion | aaaaa | aaaaa |

| coefficient of linear thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com