Efficient and environment-friendly concentrated hard surface cleaning agent

A hard surface cleaning agent and surfactant technology, applied in the field of high-efficiency and environmentally friendly concentrated hard surface cleaning agent and its preparation, can solve the problems of destroying the FMEE structure, inability to perform easy rinsing, and affecting the use of formulas, so as to improve alkali resistance , Improve decontamination performance, increase the effect of degreasing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

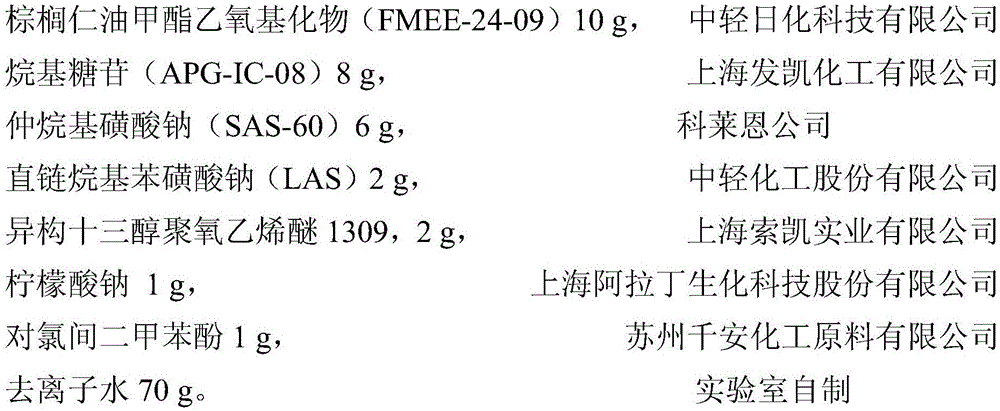

Embodiment 1

[0026]

[0027] Preparation method: mark the two reaction kettles as A and B, add a certain amount of alkyl glycoside (APG-IC-08) and tap water to A, and homogenize at 50℃; add the required fatty acid methyl ester ethoxy group (FMEE), sodium secondary alkyl sulfonate (SAS-60), sodium linear alkyl benzene sulfonate (LAS), isomeric alcohol ethoxylate and added to B, the solution in B is added to A Stir for 15 minutes to form a solution, and add additives until a solution is formed, add the antibacterial agent and the remainder of tap water to 100 mL.

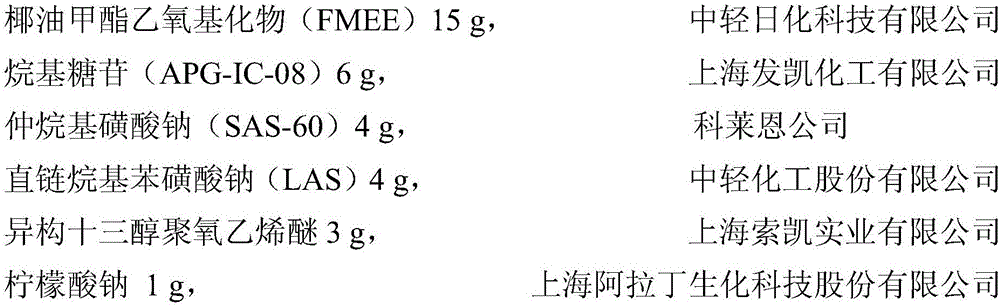

Embodiment 2

[0029]

[0030]

[0031] Preparation method: mark the two reaction kettles as A and B, add a certain amount of alkyl glycoside (APG-IC-08) and tap water to A, and homogenize at 60℃; add the required fatty acid methyl ester ethoxy group (FMEE), sodium secondary alkyl sulfonate (SAS-60), sodium linear alkylbenzene sulfonate (LAS), isomeric alcohol ethoxylate and added to B, add the solution in B to A Stir for 25 minutes to form a solution, and add additives until a solution is formed, add the antibacterial agent and the remainder of tap water to 100 mL.

Embodiment 3

[0033]

[0034] Preparation method: mark the two reaction kettles as A and B, add a certain amount of alkyl glycoside (APG-IC-08) and tap water to A, and homogenize at 60℃; add the required fatty acid methyl ester ethoxy group (FMEE), sodium secondary alkyl sulfonate (SAS-60), sodium linear alkyl benzene sulfonate (LAS), isotridecyl alcohol polyoxyethylene ether 1309 and added to B, add the solution in B Stir in A for 20 minutes to form a solution, and add additives until a solution is formed, add the antibacterial agent and the remainder of tap water to 100 mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com