Polyphenol-rich brown sugar production technology

A polyphenol-rich brown sugar and production process technology, applied in the production of sugar, sucrose production, sugar products, etc., can solve the problems of difficulty in industrialized production, turbidity, and high impurity content in brown sugar products, and achieve the effect of improving quality and nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

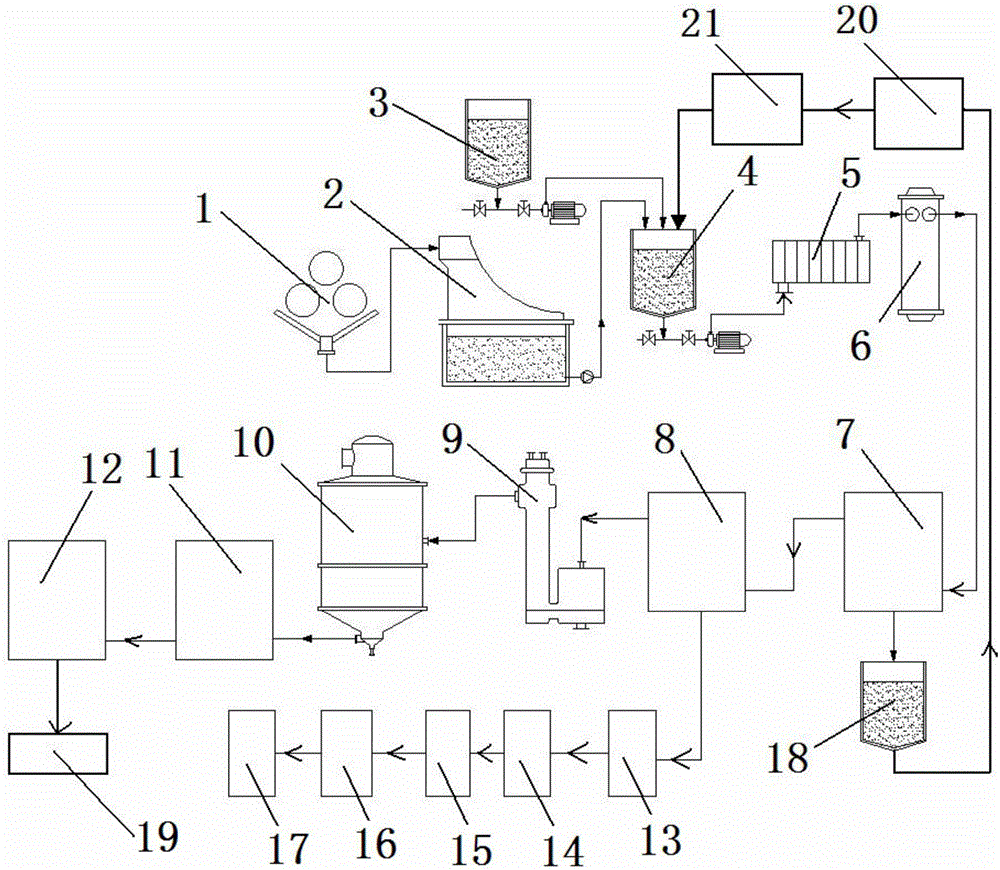

Method used

Image

Examples

Embodiment 1

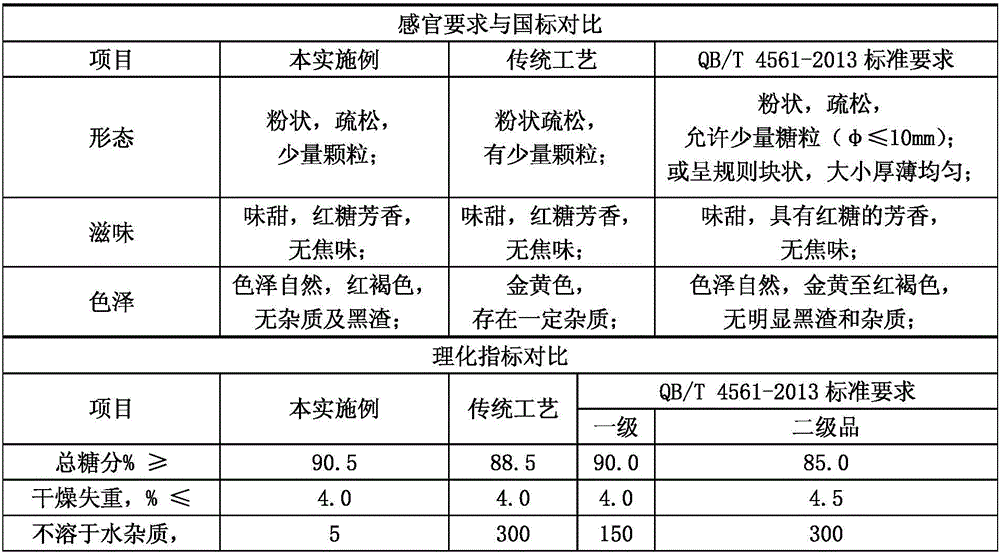

[0028] A production process of polyphenol-rich black sugar, comprising the steps of:

[0029] (1) get the sugarcane that does not remove cane tip and sugarcane leaf as raw material;

[0030] (2) Squeezing sugarcane to obtain mixed juice, using a 100-mesh vibrating sieve to remove large particles of impurities such as bagasse, and then using a 200-mesh rotary vibrating sieve to remove small particles of impurities to obtain a raw material solution;

[0031] (3) Add lime milk to the raw material liquid to adjust the pH to 7.5, then heat it to 60°C through a tubular heat exchanger, pump it to the buffer tank, and heat it to 85°C with steam to obtain a heated raw material liquid;

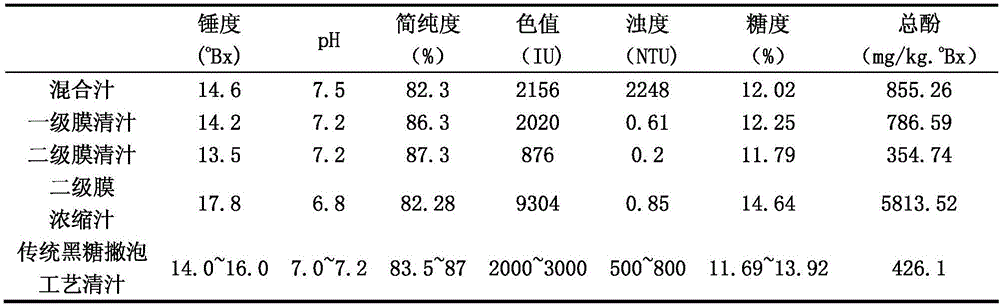

[0032] (4) Clarify and filter through a 50nm first-class ceramic membrane, the transmembrane pressure difference is 0.45Mpa, the membrane surface flow rate is 4m / s, and the volume concentration factor is 10 to remove most of the non-sugar impurities such as bacteria, ash, and colloid in the mixed juice ...

Embodiment 2

[0044] A production process of polyphenol-rich black sugar, comprising the steps of:

[0045] (1) get the sugarcane that does not remove cane tip and sugarcane leaf as raw material;

[0046] (2) Sugarcane is squeezed to obtain mixed juice, and a 50-mesh vibrating sieve is used to remove large particles of sugarcane pulp such as bagasse, and then filtered with a 250-mesh rotary vibrating sieve to remove small particles of impurities to obtain a raw material solution;

[0047] (2) Add lime milk to the raw material liquid to adjust the pH to 7.0, then heat it to 55°C through a tubular heat exchanger, pump it to the buffer tank of the raw material tank, and heat it to 80°C with steam to obtain a heated raw material liquid;

[0048] (3) Clarify and filter through a 100nm first-level ceramic membrane, with a transmembrane pressure difference of 0.35Mpa, a membrane surface flow rate of 4.5m / s, and a volume concentration factor of 10 to remove most impurities such as bacteria, ash, and ...

Embodiment 3

[0060] A production process of polyphenol-rich black sugar, comprising the steps of:

[0061] (1) Sugarcane is squeezed to obtain mixed juice, and a 80-mesh vibrating sieve is used to remove large-particle impurities such as bagasse, and then a 300-mesh rotary vibrating sieve is used to remove small-particle impurities to obtain a raw material liquid;

[0062] (2) Add lime milk to the raw material liquid to adjust the pH to 7.2, then heat it to 65°C through a tubular heat exchanger, pump it to the buffer tank of the raw material tank, and heat it to 90°C with steam to obtain a heated raw material liquid;

[0063] (3) Carry out clarification and filtration through a 200nm first-class ceramic membrane, the transmembrane pressure difference is 0.25Mpa, the membrane surface flow velocity is 5m / s, and the volume concentration multiple is 10, so as to remove most of the impurities such as bacteria, ash, and colloid in the mixed juice, and obtain The first-level membrane clear juice ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com