Alumina whisker preparation method

An alumina whisker and carbon dioxide technology, applied in the chemical industry, can solve the problems of difficult filtration and high cost, and achieve the effects of low cost, simple equipment and easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Configure aluminum sulfate solution 0.4mol / L, put calcium carbonate into the reaction kettle, and pour hydrochloric acid. Close the reaction kettle and stir until the reaction is complete, pass carbon dioxide into the ammonia water container and then pass into the above-mentioned aluminum sulfate solution. Stir at 300 rpm for 20 hours until the reaction is complete. 0.6 MPa of carbon dioxide is introduced into the airtight container for pressure filtration. Dry at 100°C and calcined at 1200°C for 1 hour to obtain alumina whiskers.

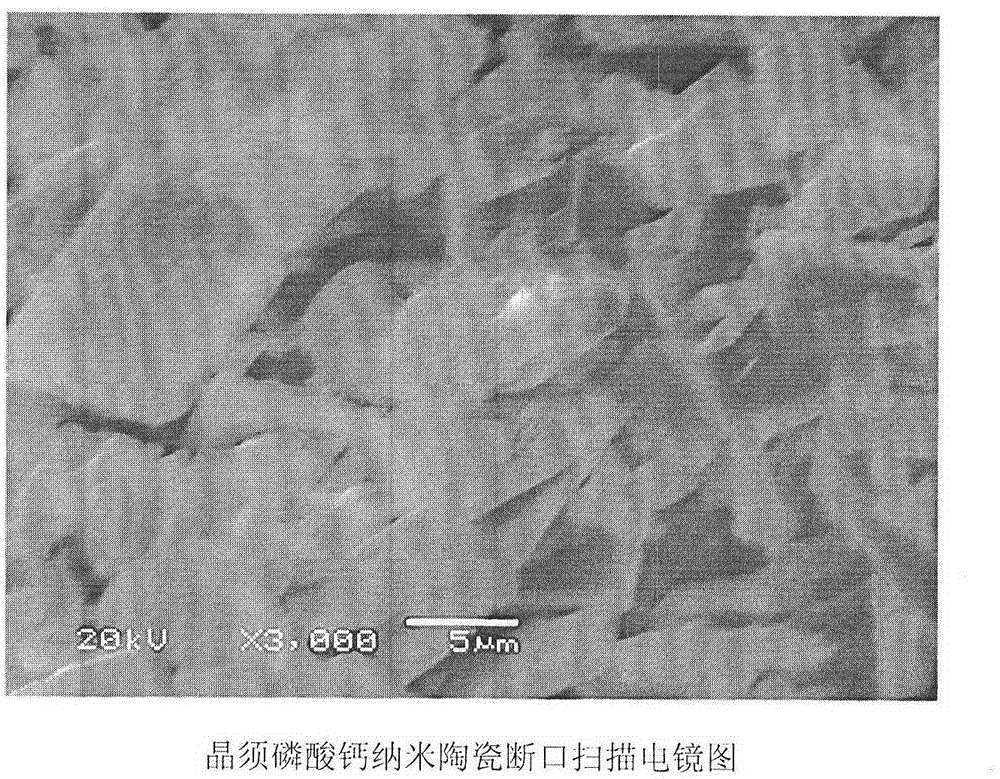

[0020] The SEM scanning image of the final alumina whisker product is shown in Fig. 1 . The average diameter of the alumina whiskers is 50-100 nm, and the average length of the alumina whiskers is 1-5 μm.

Embodiment 2

[0022] Configure aluminum sulfate solution 0.45mol / L, put calcium carbonate into the reaction kettle, and quickly pour hydrochloric acid. Close the reaction kettle, stir until the reaction is complete, pass carbon dioxide into the ammonia water container and then pass into the above-mentioned aluminum sulfate solution. Stir at 400 rpm for 20 hours until the reaction is complete. 0.5 MPa of carbon dioxide is introduced into the airtight container for pressure filtration. Dry at 100 degrees and calcined at 1150 degrees for 1 hour. Alumina whiskers are obtained.

Embodiment 3

[0024] Configure aluminum sulfate solution 0.5mol / L, put calcium carbonate into the reaction kettle, and quickly pour hydrochloric acid. Close the reaction kettle, stir until the reaction is complete, and pass carbon dioxide into the above-mentioned aluminum sulfate solution. Stir at 300 rpm for 20 hours until the reaction is complete. 0.4MPa carbon dioxide is passed through the airtight container for pressure filtration. Dry at 100 degrees and calcined at 1200 degrees for 1 hour. Alumina whiskers are obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com