Application of trace-Pt modified porous ZnO composite material in detection of benzene hydrocarbon gases

A composite material and gas detection technology, applied in the field of gas sensing, can solve the problems of high precious metal content, unfavorable production cost, complicated preparation process, etc., and achieve the effect of less dosage and less cost impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Preparation of Pt-modified ZnO precursor: 0.30 g of zinc acetate dihydrate and 0.30 mg of chloroplatinic acid hexahydrate were dissolved in a mixed solvent consisting of 13 mL of glycerol and 40 mL of isopropanol, and then transferred to a reaction kettle React at 160°C for 2 hours, then cool naturally to room temperature, and centrifuge with ethanol to obtain the Pt-modified ZnO precursor;

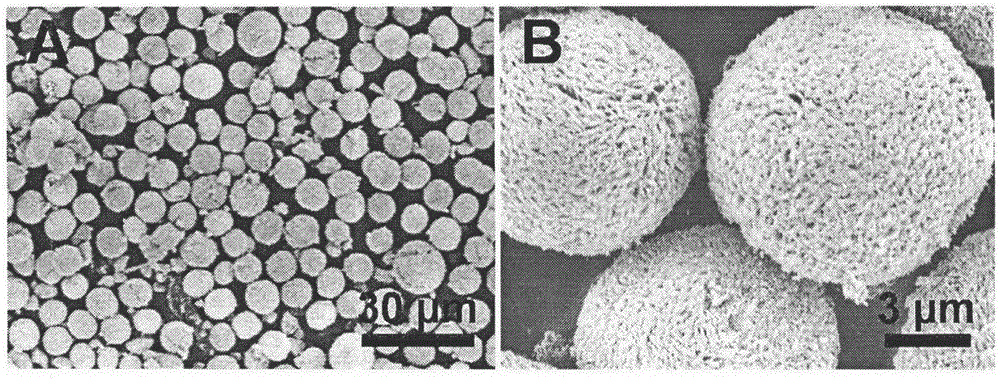

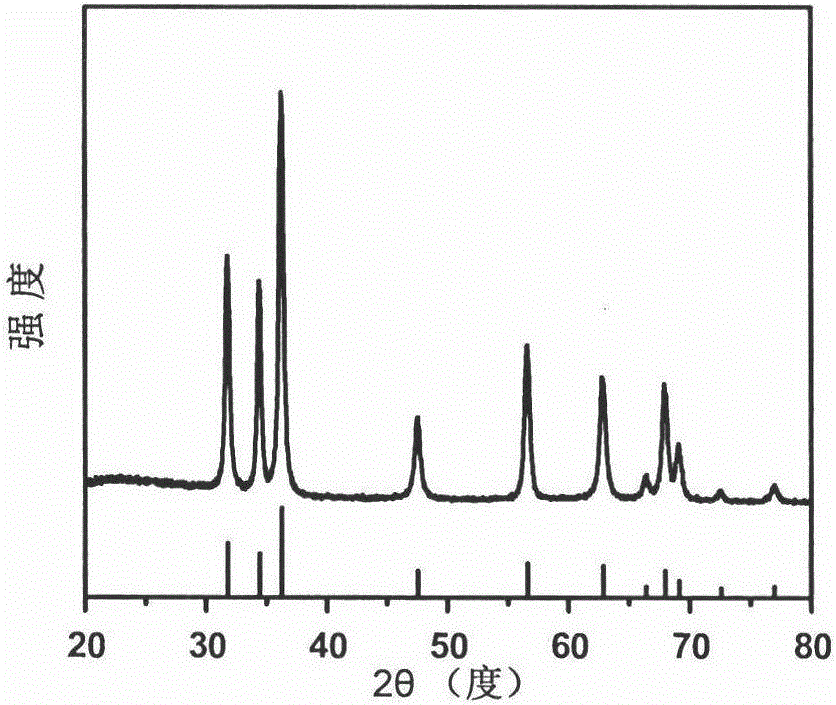

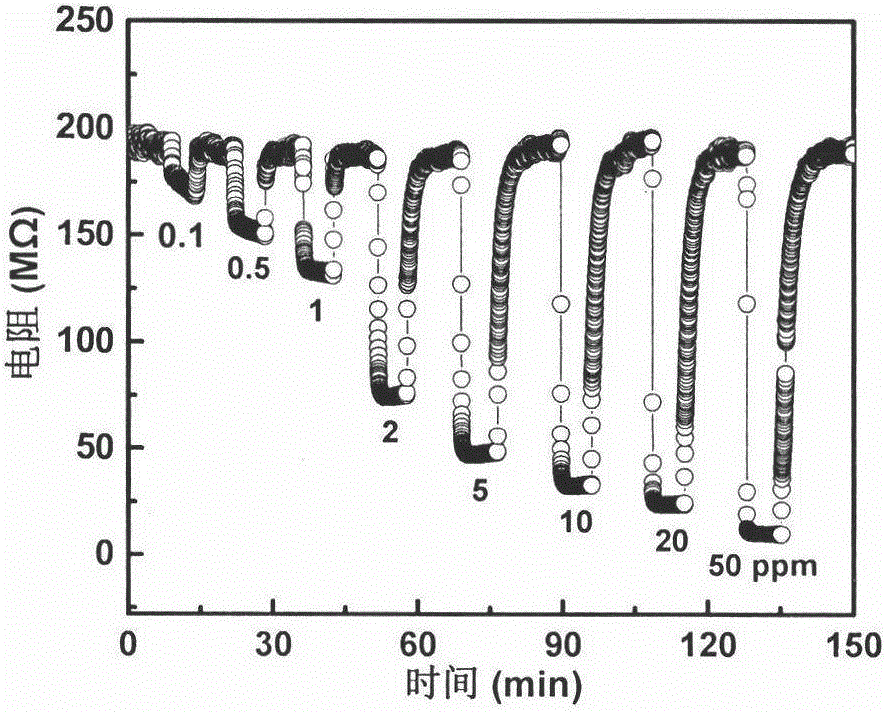

[0021] 2) Preparation of Pt-modified porous ZnO composite material: the above-mentioned precursor powder was placed in a muffle furnace and calcined at 400° C. for 2 hours in an air atmosphere to obtain the Pt-modified porous ZnO microsphere composite material ( Such as figure 1 ). The composition and structure of the above samples were analyzed, figure 2 It is the XRD spectrum of Pt-modified porous ZnO microspheres. It can be observed from the figure that the peak positions of all diffraction peaks match PDF#36-1451. Since the amount of Pt modification in the sample is very ...

Embodiment 2

[0025] The same as in Example 1, except that the amount of chloroplatinic acid hexahydrate was changed to 0.60 mg. The response value of the composite material to 100ppm benzene is 35, the response time is 4s, the recovery time is 200s, and the detection limit of benzene is 500ppb.

Embodiment 3

[0027] Same as Example 1, except that the consumption of chloroplatinic acid hexahydrate was changed to 0.45 mg. The response value of the composite material to 100ppm benzene is 48, the response time is 4s, the recovery time is 250s, and the detection limit of benzene is 500ppb.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com