Lithium ion secondary battery

A secondary battery, lithium ion technology, applied in the field of non-aqueous electrolyte batteries, can solve the problems of cathode deterioration, attacking lithium-nickel composite oxides, etc., to achieve the effect of preventing deterioration and improving cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

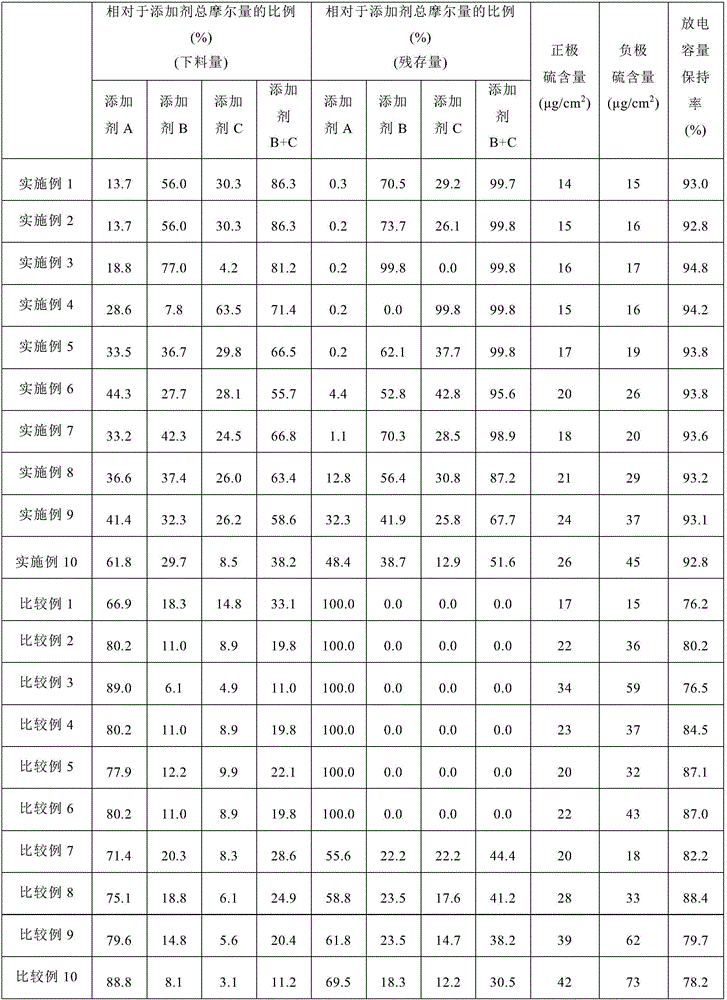

Examples

Embodiment

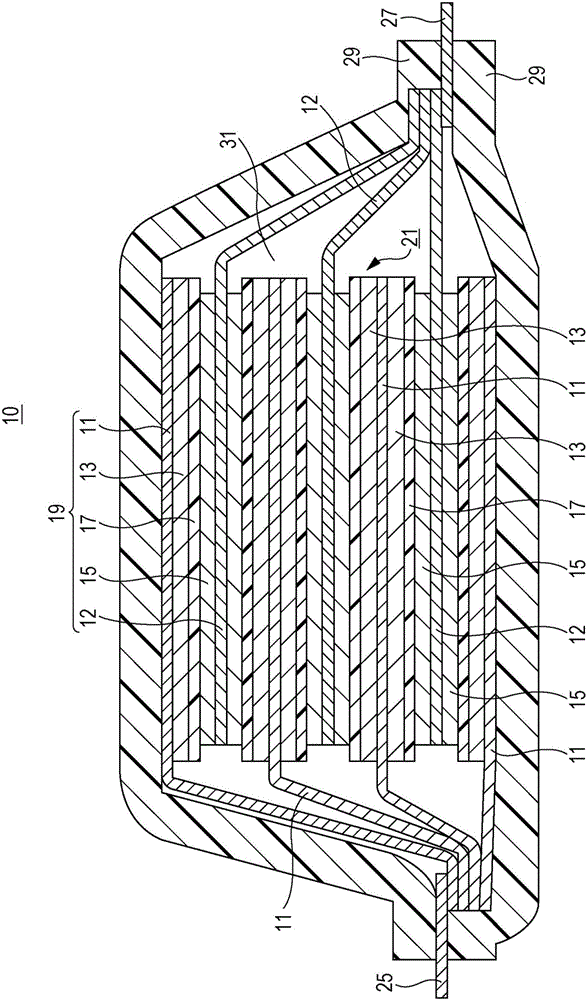

[0032]

[0033] As the negative electrode active material, a 3.4m 2 / g graphite powder with BET specific surface area. The graphite powder, as a conductive additive, has a 62m 2 Carbon black powder (hereinafter referred to as "CB") with a BET specific surface area of / g, carboxymethylcellulose (hereinafter referred to as "CMC") as a binder resin, and styrene-butadiene copolymer latex (hereinafter referred to as referred to as "SBR") was mixed at a ratio of solid component mass ratio CB:CMC:SBR=0.3:1.0:2.0. After adding the obtained mixture to ion-exchanged water, it stirred with ion-exchanged water. Thus, a slurry comprising the material uniformly dispersed in water was prepared. The obtained slurry was coated on a copper foil having a thickness of 10 μm as a negative electrode current collector. Next, water was evaporated by heating the electrode at 125°C for 10 minutes. Thus, a negative electrode active material layer was formed. In addition, a negative electrode h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com