Preparation method of high(001)-crystal-facet ultrathin anatase nanosheet self-assembled microspheres

A technology of anatase and nanosheets, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of high cost and complicated process, and achieve the effect of fast reaction speed, simple process and high photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

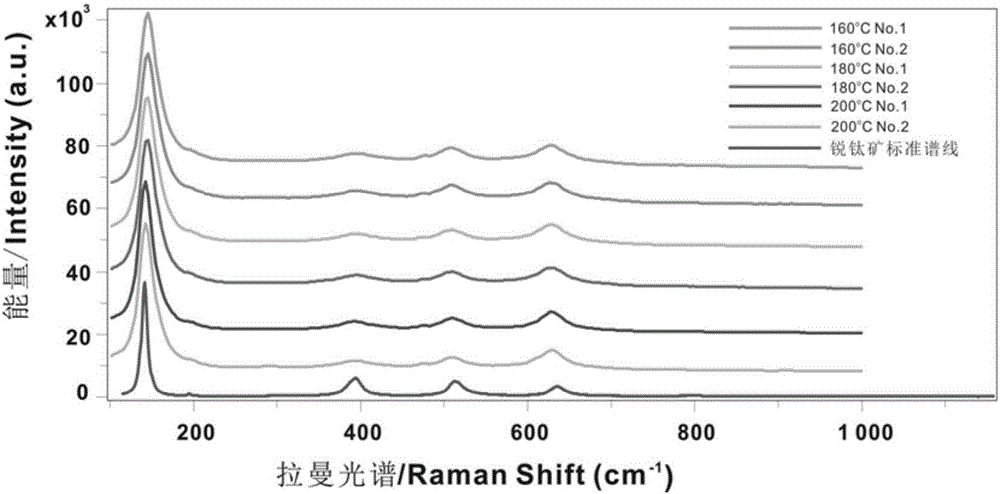

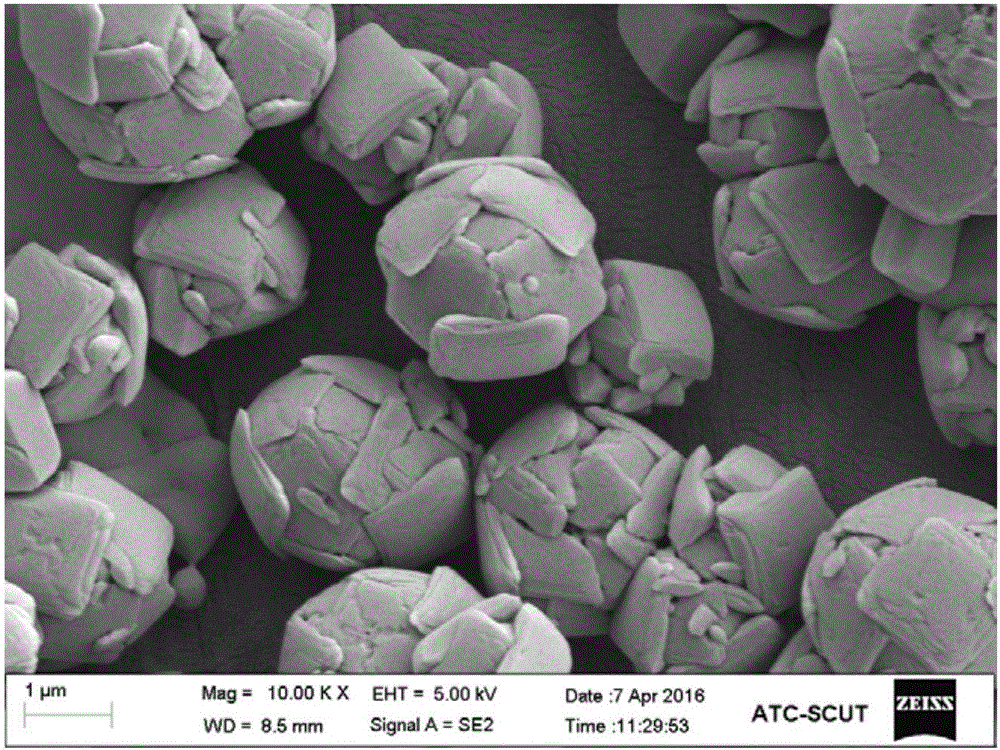

[0038] The preparation method of the high (001) surface ultrathin anatase nanosheet self-assembled microspheres provided by the present embodiment comprises the following steps:

[0039] (1) 0.48g potassium fluotitanate (K 2 TiF 6 , commercially available, the same below) was dissolved in 100mL deionized water and fully dissolved to obtain a 0.02mol / L reaction solution;

[0040] (2) the reaction solution prepared in step (1) is packed in the hydrothermal reactor of polytetrafluoroethylene liner, and filling degree is controlled to be about 70%, and a polytetrafluoroethylene thin plate is placed at the bottom of the reaction kettle, and the thickness of the thin plate is The shape matches the size of the bottom of the hydrothermal autoclave. After sealing the hydrothermal reaction kettle, put the reaction kettle into the heating box and raise the temperature to 200°C for 2 hours;

[0041] (3) After the reaction is over, take out the hydrothermal reactor in step (2) from the h...

Embodiment 2

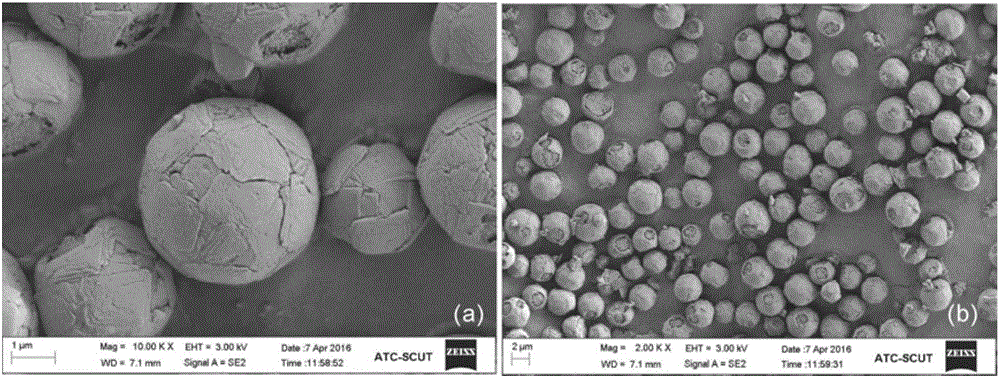

[0046] The preparation method of the high (001) surface ultrathin anatase nanosheet self-assembled microspheres provided by the present embodiment comprises the following steps:

[0047] (1) 0.96g potassium hexafluorotitanate (K 2 TiF 6 ) was dissolved in 100mL deionized water and fully dissolved to obtain a 0.04mol / L reaction solution;

[0048] (2) the reaction solution prepared in the step (1) is packed in the hydrothermal kettle of the polytetrafluoroethylene liner, and the filling degree is controlled to be about 60%, and a polytetrafluoroethylene sheet is placed at the bottom of the reaction kettle, and the water is sealed. After heating the reaction kettle, put the reaction kettle into a heating box, and raise the temperature to 180°C for 2 hours;

[0049] (3) After the reaction is over, take out the hydrothermal reactor in step (2) from the heating box and cool it down naturally. After the temperature of the hydrothermal reactor drops to room temperature, open the rea...

Embodiment 3

[0054] The preparation method of the high (001) surface ultrathin anatase nanosheet self-assembled microspheres provided by the present embodiment comprises the following steps:

[0055] (1) 0.96g potassium hexafluorotitanate (K 2 TiF 6 ) was dissolved in 100mL deionized water and fully dissolved to obtain a 0.04mol / L reaction solution;

[0056] (2) the reaction solution that step (1) is made is packed in the hydrothermal reaction kettle of polytetrafluoroethylene liner, and filling degree is controlled to be about 80%, and a polytetrafluoroethylene thin plate is placed at the bottom of the reaction kettle, and the water is sealed. After heating the reaction kettle, put the reaction kettle into a heating box, and raise the temperature to 160°C for 3 hours;

[0057] (3) After the reaction is over, take out the hydrothermal reactor in step (2) from the heating box and cool it down naturally. After the temperature of the hydrothermal reactor drops to room temperature, open the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com