Synthesis method of self-repairing elastomer material based on eucommia rubber

A technology of elastomer materials and synthesis methods, applied in the field of synthesis of self-healing elastomer materials, can solve problems such as difficult to be repaired in time, macro cracks, material failure, etc., and achieve low-cost raw materials, easy-to-obtain raw materials, and mature process routes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

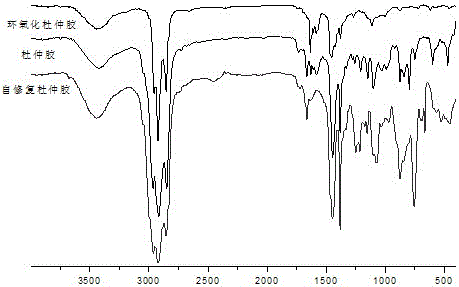

[0023] Add 10 g of eucommia gum to 120 ml of petroleum ether, raise the temperature to 42°C until completely dissolved, continue to add 100 ml of deionized water and stir to obtain a stable emulsion of eucommia gum. To this was added 6 ml of formic acid and H 2 o 2 20 ml, and epoxidation reaction at 42°C for 5h. After the epoxidation reaction, the emulsion system was adjusted to pH=5 with 10% aqueous sodium hydroxide solution, and 5 ml of methyltriethoxysilane, 10.0 ml of formic acid, and 5 ml of absolute ethanol were added to continue the reaction for 3 h. The product was precipitated by absolute ethanol, washed, and dried in vacuo to constant weight.

Embodiment 2

[0025] Add 20 g of eucommia gum to 260 ml of cyclohexane, raise the temperature to 60°C until completely dissolved, continue to add 150 ml of deionized water and stir to obtain a stable emulsion of eucommia gum. To this was added 6 ml of formic acid and H 2 o 2 30ml, epoxidation reaction 2 h. After the epoxidation reaction, the pH of the system was adjusted to 9 with ammonia water. A solution made of 6 ml dichlorodimethylsilane, 12 ml absolute ethanol, 12 ml deionized water and 0.3 ml hydrochloric acid was added dropwise at a constant speed, and the reaction was continued for 2 h after the addition was completed. The product was precipitated by absolute ethanol, washed, and dried in vacuo to constant weight.

Embodiment 3

[0027] Dissolve 20 g of Eucommia gum in 260 ml of cyclohexane, raise the temperature to 50°C until completely dissolved, continue to add 150 ml of deionized water and stir to obtain a stable emulsion of Eucommia gum. To this was added 10 ml of formic acid and H 2 o 230 ml, and epoxidized at 50°C for 3 h. After the epoxidation reaction, the pH of the system was adjusted to 4 with 10% aqueous sodium hydroxide solution. 8 ml of 3-aminopropyltrihydroxysilane, 26 ml of formic acid, 10 ml of absolute ethanol, and 10 ml of deionized water were successively added thereto, and the reaction was continued for 2 h. The product was precipitated by absolute ethanol, washed, and dried in vacuo to constant weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com