Graphene/nickel hydroxide composite material and preparation method thereof, and electrode material

A nickel hydroxide and composite material technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, can solve the problems of complex process, poor uniformity, and unsuitable for large-scale industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The embodiment of the present invention discloses a preparation method of graphene / nickel hydroxide composite material, comprising:

[0029] Mix graphene oxide, water, hexamethylenetetramine and a nickel source, heat, and react to obtain a graphene / nickel hydroxide composite material; the nickel source is capable of ionizing Ni in water 2+ source of nickel.

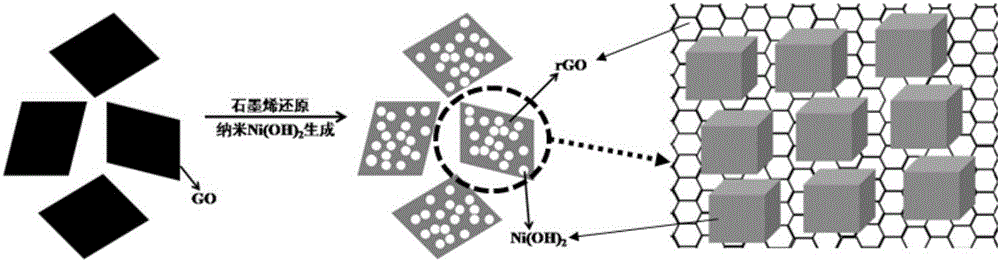

[0030] Such as figure 2 as shown, figure 2 The model diagram prepared for the graphene / nickel hydroxide composite material provided by the present invention, as can be seen from the figure, the application utilizes the hydrothermal method with simple process to simultaneously carry out the generation of nano-nickel hydroxide and the reduction of graphene, from the source and the microcosm The two-phase composite is carried out on the layer, and the nano-nickel hydroxide is uniformly attached to the layered graphene to form a composite material. The composite material prepared by this application has the advant...

Embodiment 1

[0051] Take 0.1g of graphene oxide and disperse it into 100ml of aqueous solution, ultrasonicate with 1000w power ultrasonic equipment for 1h, then add a certain amount of nickel sulfate (NiSO 4 ·6H 2 O) and hexamethylenetetramine ((CH 2 ) 6 N 4 ) were prepared to 0.5mol / L, stirred by magnetic force for 30min, poured the homogeneous ultrasonic solution into the polytetrafluoroethylene reaction kettle, sealed the water heating tank, heated to 180°C and kept it for 20h; Freeze-dried after washing with water to obtain the final product.

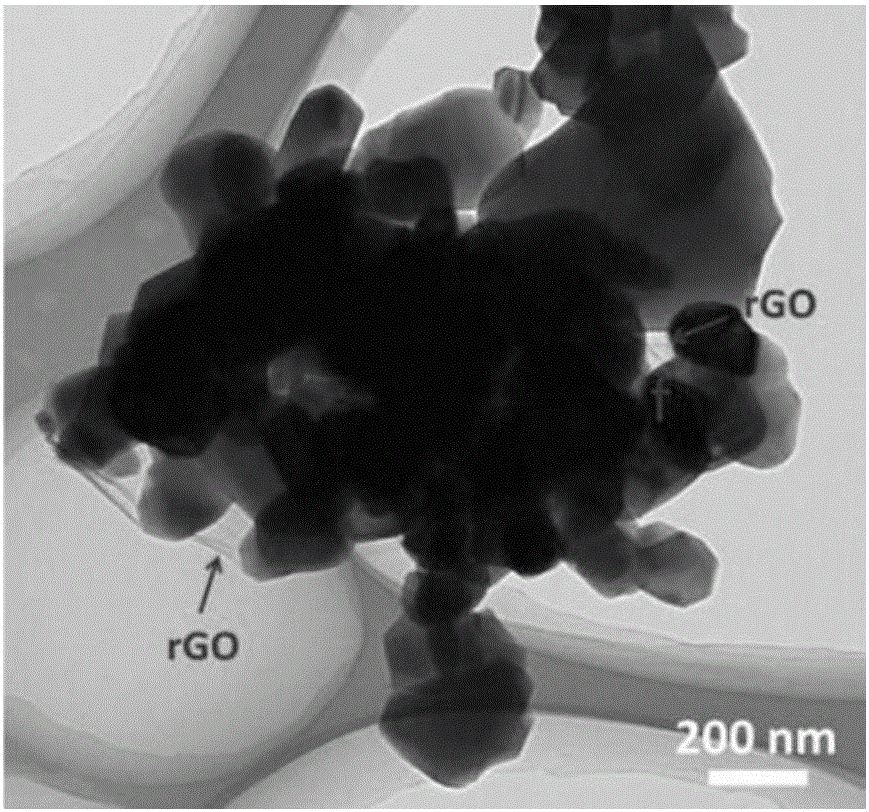

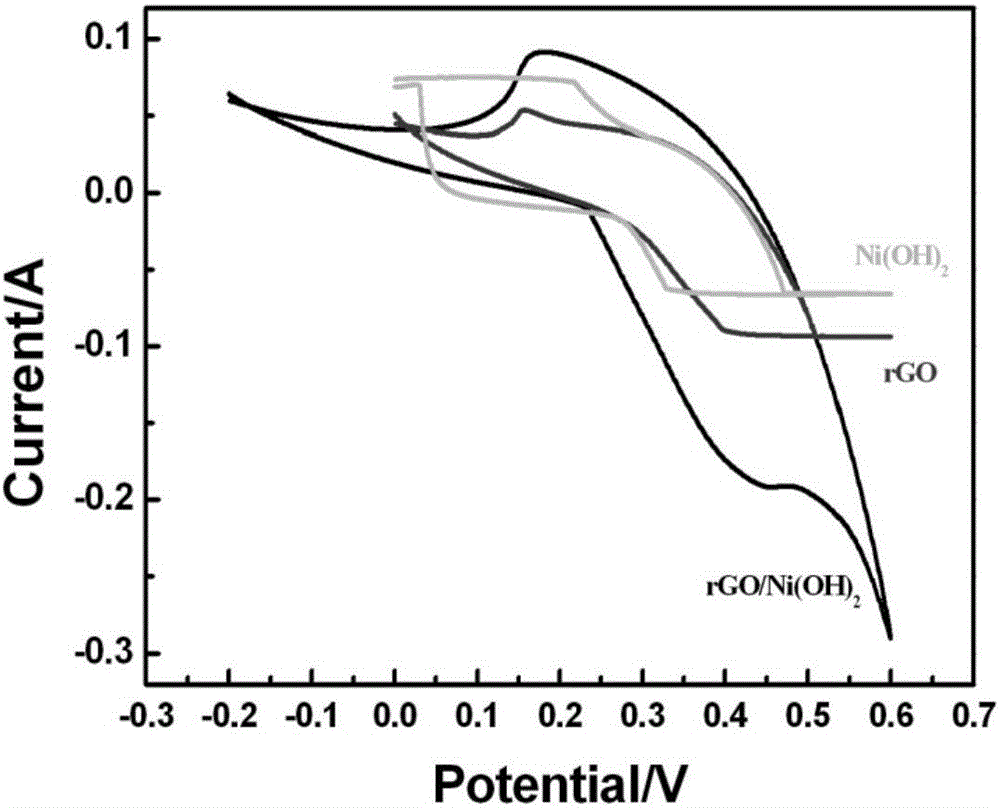

[0052] Such as figure 1 as shown, figure 1 For the TEM photo of the graphene / nickel hydroxide composite material prepared by the present embodiment, graphene (arrow place) among the figure is the large tulle layer of specific surface area, and nanometer nickel hydroxide is attached on the graphene layer, forms graphene / nickel hydroxide Nickel hydroxide composite structure; image 3 and Figure 4 single-phase Ni(OH) 2 , rGO and rGO / Ni(OH...

Embodiment 2

[0057] Take 0.05g of graphene oxide and disperse it into 100ml of aqueous solution, ultrasonicate with 1000w power ultrasonic equipment for 1h, then add a certain amount of nickel sulfate (NiSO 4 ·6H 2 O) and hexamethylenetetramine ((CH 2 ) 6 N 4 ) were all prepared to 0.4mol / L, stirred by magnetic force for 30min, poured the homogeneous ultrasonic solution into the polytetrafluoroethylene reaction kettle, sealed the water heating tank, heated to 180°C and kept it for 18h; Freeze-dried after washing with water to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com